Self-walking device of large transformer

A technology of self-propelled devices and transformers, which is applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of adverse effects on economic and social benefits of enterprises, slow transfer process, and restricted construction period, etc., to achieve economic benefits It has considerable social benefits, shortens the construction period of the project, and has the effect of coherent delivery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

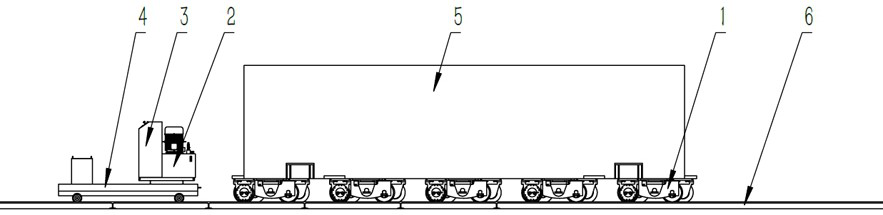

[0023] Such as figure 1 , figure 2 , the present invention provides a large-scale transformer self-propelled device, the self-propelled device is composed of a traveling wheel mechanism 1, a hydraulic drive system 2 and a control cabinet 3, and the hydraulic drive system 2 and the control cabinet 3 are integrated in a driven travel mechanism 4 Above, this scheme has ten sets of traveling wheel mechanisms 1 to form a traveling wheel set, which is divided into left and right columns, with five sets of traveling wheel mechanisms 1 in each column, carrying the transformer 5 and walking on the track 6, and the integrated trolley 4 is hung on the track through a hard connection. Connected to the transformer 5, the hydraulic pump station 2 supplies oil to the traveling wheel mechanism 1 through the high-pressure oil pipe, and the PLC system in the control ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com