Bagged washing powder filling, sealing and packaging device

A filling and sealing, washing powder technology, applied in packaging, packaging recycling, transportation packaging, etc., can solve the problems of low work efficiency, waste, and difficulty in keeping the filling volume consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

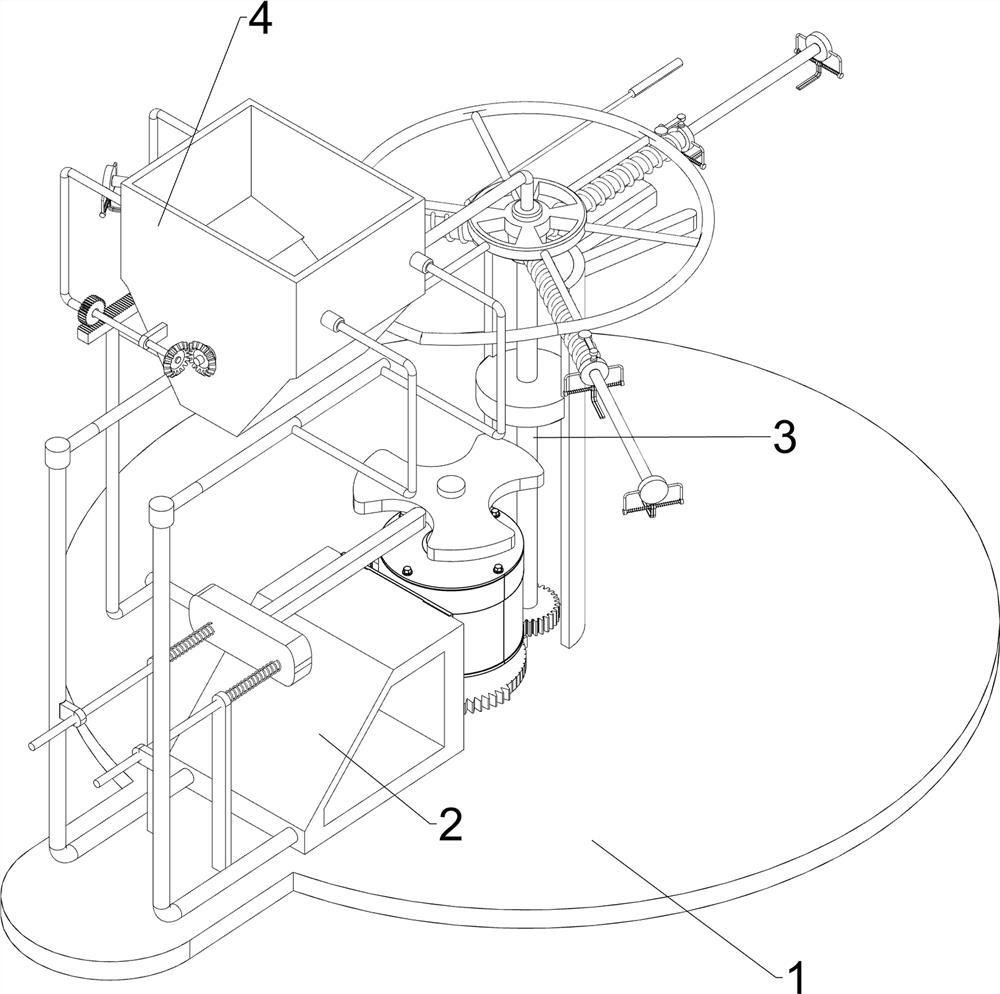

[0022] Such as Figure 1-4 As shown, a bagged washing powder filling, sealing and packaging device includes a bottom plate 1, a fixing seat 2, a transmission mechanism 3 and a filling mechanism 4. The fixing seat 2 is arranged on the left side of the top of the bottom There is a transmission mechanism 3, and a filling mechanism 4 is arranged on the left side of the fixed seat 2.

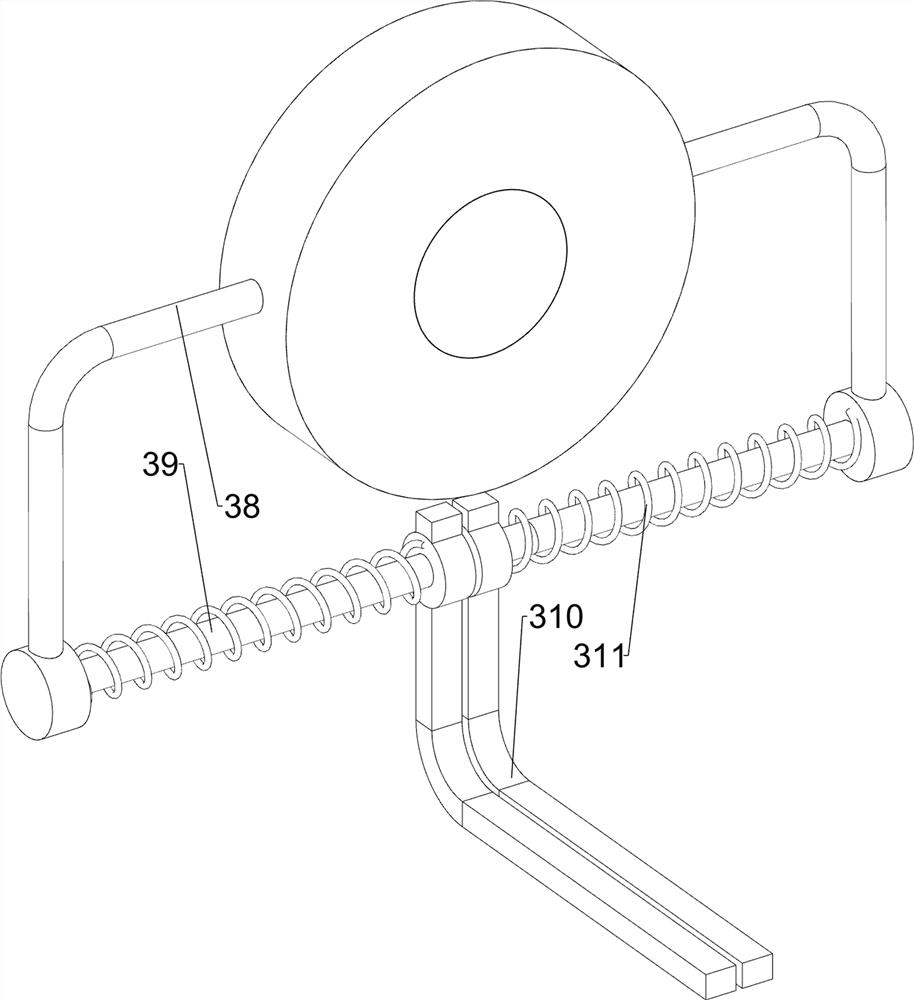

[0023] The transmission mechanism 3 includes a pillar 31, a bearing 32, a first rotating shaft 33, an axle sleeve 34, a sliding shaft 35, a sliding sleeve 36, a round block 37, an L-shaped rod 38, a first guide rod 39, a clip 310, a first elastic Part 311, second elastic member 312, biaxial motor 313, missing gear 314 and first round gear 315, a pillar 31 is arranged in the middle of the top of the bottom plate 1, a bearing 32 is arranged on the upper side of the pillar 31, and a first rotating shaft is arranged in the bearing 32 33. The first rotating shaft 33 is rotationally connected with the bot...

Embodiment 2

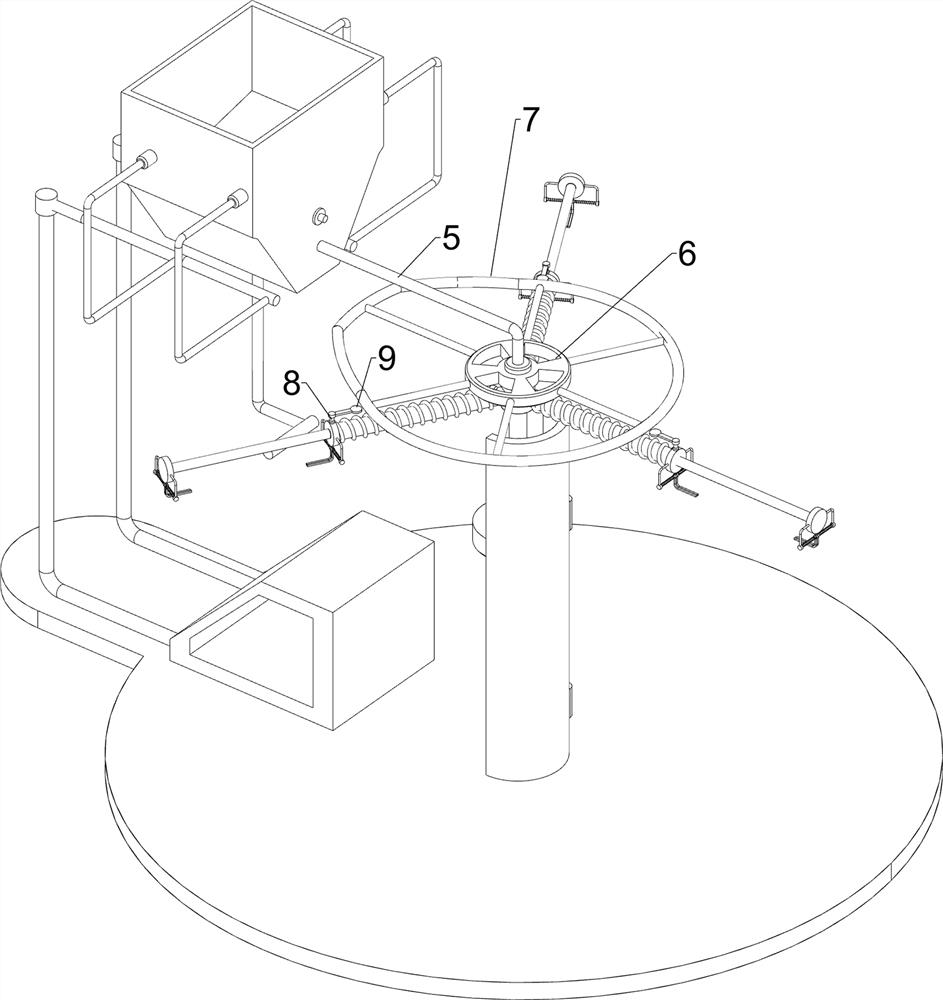

[0027] Such as Figure 5-6 As shown, on the basis of Example 1, a bagged washing powder filling and sealing packaging device also includes a second fixing rod 5, a fixing frame 6, a ring guide rail 7, a third fixing rod 8 and a top block 9, The right side of the funnel 44 is provided with a second fixed rod 5, the right end of the second fixed rod 5 is provided with a fixed mount 6, the outer side of the fixed mount 6 is provided with an annular guide rail 7, the top of the sliding sleeve 36 is provided with a third fixed rod 8, and the third fixed rod 8 A top block 9 is provided near the side of the pillar 31, and the top block 9 contacts and fits with the ring guide rail 7.

[0028] When the clip 310 clamps the washing powder packaging bag and rotates close to the funnel 44, the top block 9 drives the sliding sleeve 36 to move on the sliding shaft 35 in the contact and fit of the ring guide rail 7 and moves close to the round block 37 to open the opening of the washing powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com