Preparation method of PVA fibers

A fiber and spinning dope technology, applied in the field of PVA fiber preparation, can solve the problems of increasing the risk of foreign matter left on the wound surface, and achieve the effect of less impurities and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

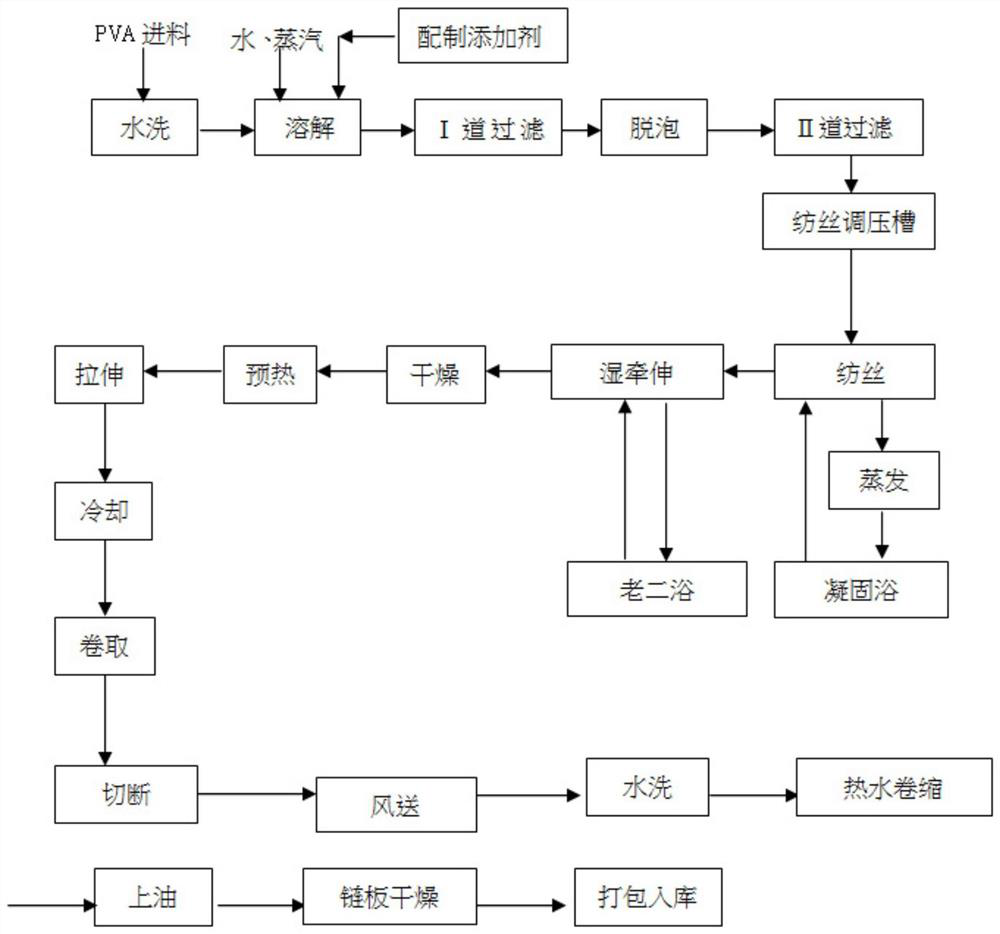

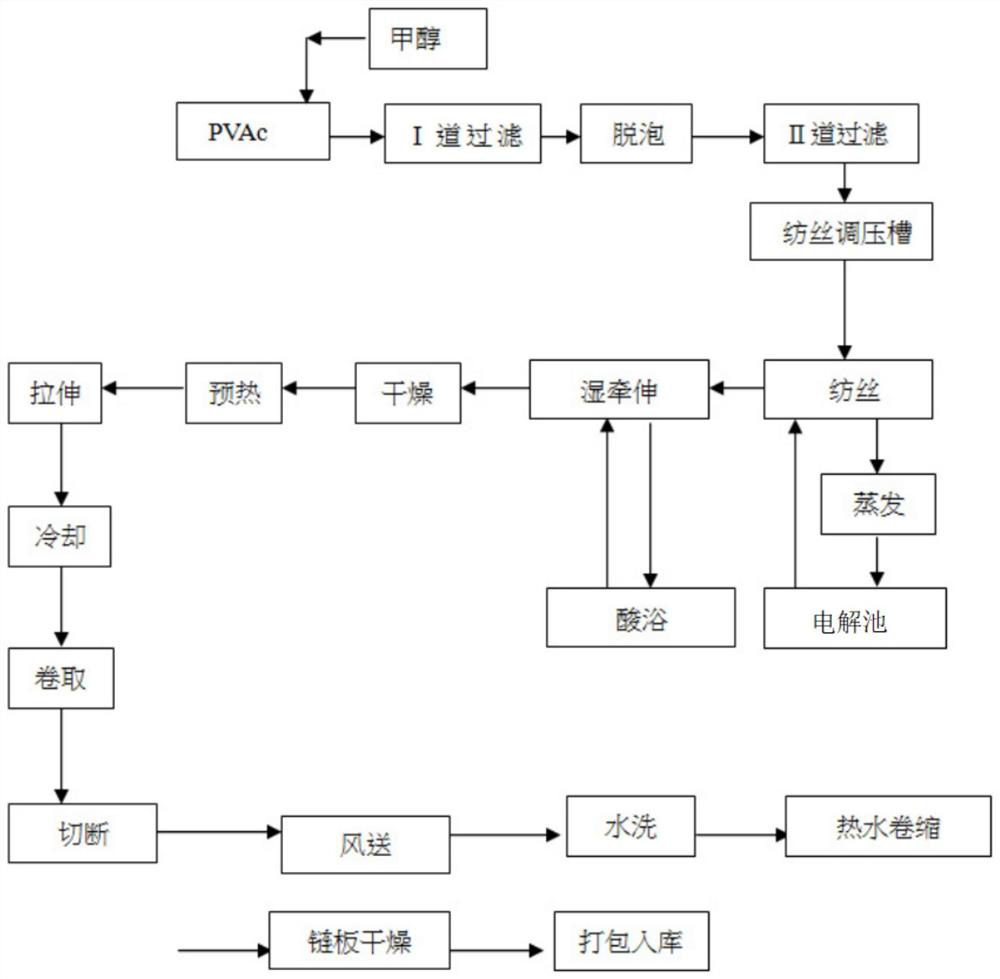

[0039] Such as figure 2 Shown, a kind of preparation method of PVA fiber comprises the following contents:

[0040] Step 1, preparing spinning dope;

[0041] The raw material adopts PVAc, and after adding methanol to dissolve, it is filtered to obtain the spinning stock solution; as an example, the concentration ratio range of PVAc and methanol in the spinning stock solution is 15-80 to 20-85; as a kind of preference, the spinning stock solution The mass fraction of PVAc is 40-45%, and the mass fraction of methanol is 55-60%.

[0042] Step 2, spinning;

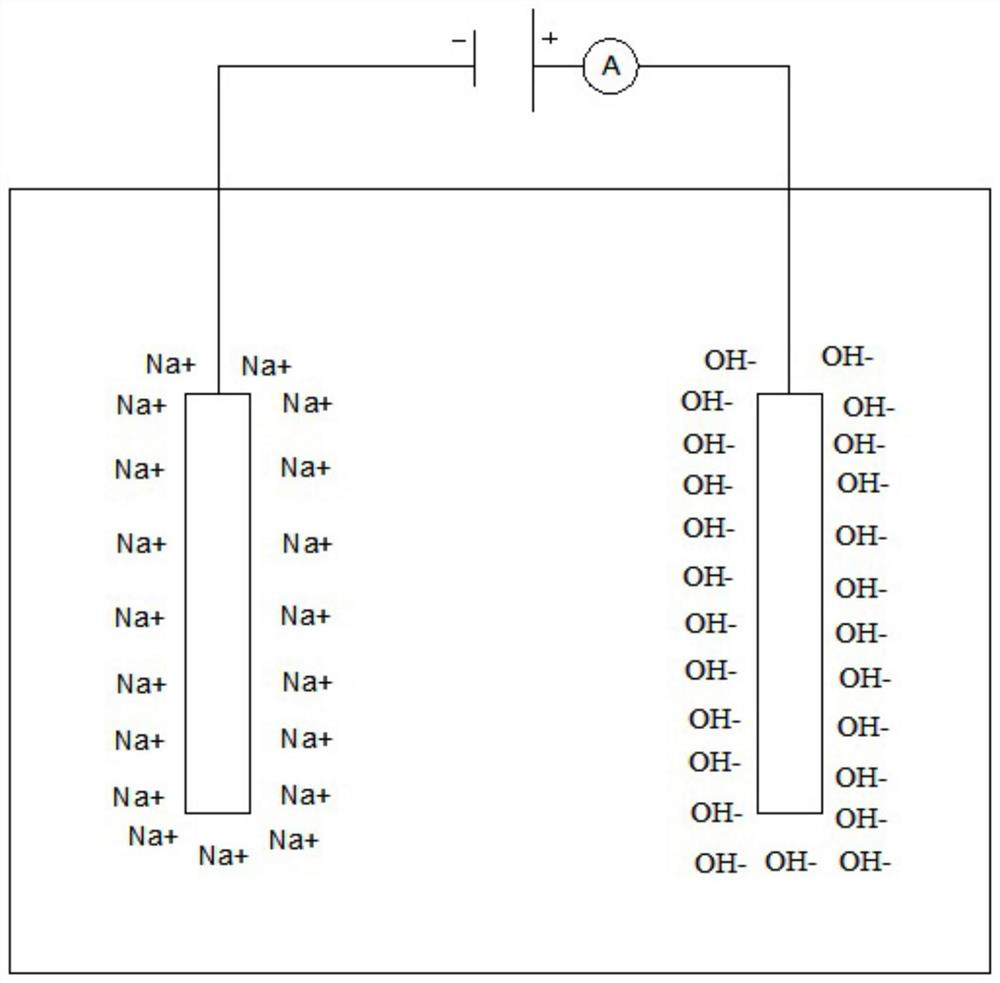

[0043] Under the conditions of 0.05-0.6MPa and temperature of 45-55°C, the spinning stock solution is injected into the spinneret, and the ejected fibers enter the DC electrolytic cell, such as image 3 As shown, the coagulation bath is carried out, the DC voltage of the DC electrolytic cell is 1.23V-200V, and a series of reactions of alcoholysis, electrolytic catalytic alcoholysis and alcohol leverage are carried out; the...

Embodiment 1

[0049] first step,

[0050] Weigh 180 kg of polyvinyl acetate particles and 270 kg of methanol solution respectively, and add polyvinyl acetate first, followed by methanol, and add them to the reaction kettle. The temperature rises to 50 ° C to fully dissolve polyvinyl acetate to in methanol solution. The concentration ratio range of PVAc to methanol in the spinning dope is 2:3.

[0051] The obtained PVAc / MT solution is filtered through stage I, degassed, and filtered through stage II, and the PVAc / MT solution is introduced into the spinning pressure regulating tank.

[0052] In the second step, the electrolyte

[0053] Add 700 kilograms of water in the insulator electrolytic cell, drop into 270 kilograms of potassium hydroxide solids and 30 kilograms of 99% isopropanol in water.

[0054] ②Electrolytic cell

[0055] Combined with the process flow chart, an anode and a cathode electrode are formed in the electrolytic cell through the wire, and the electrode material is grap...

Embodiment 2

[0064] first step,

[0065] Weigh 200 kg of polyvinyl acetate particles and 250 kg of methanol solution respectively, and add polyvinyl acetate first, followed by methanol, and add them to the reaction kettle. The temperature rises to 55 ° C to fully dissolve polyvinyl acetate to in methanol solution. The concentration ratio of PVAc to methanol in the spinning dope ranges from 4 to 5.

[0066] The obtained PVAc / MT solution is filtered through stage I, degassed, and filtered through stage II, and the PVAc / MT solution is introduced into the spinning pressure regulating tank.

[0067] second step,

[0068] ①Electrolyte

[0069] Add 700 kilograms of water in the insulator electrolytic cell, drop into the alcohol of 280 kilograms of potassium hydroxide and 20 kilograms of 99% in water.

[0070] ②Electrolytic cell

[0071] Combined with the process flow chart, an anode and a cathode electrode are formed in the electrolytic cell through the wire, and the electrode material is gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com