Medium-voltage fireproof cable and preparation method thereof

A fireproof cable, medium voltage technology, applied in the direction of cable/conductor manufacturing, insulated cable, bendable cable, etc., can solve the problem of fireproof cable losing normal power transmission capacity, insufficient fire resistance, etc. Good, improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

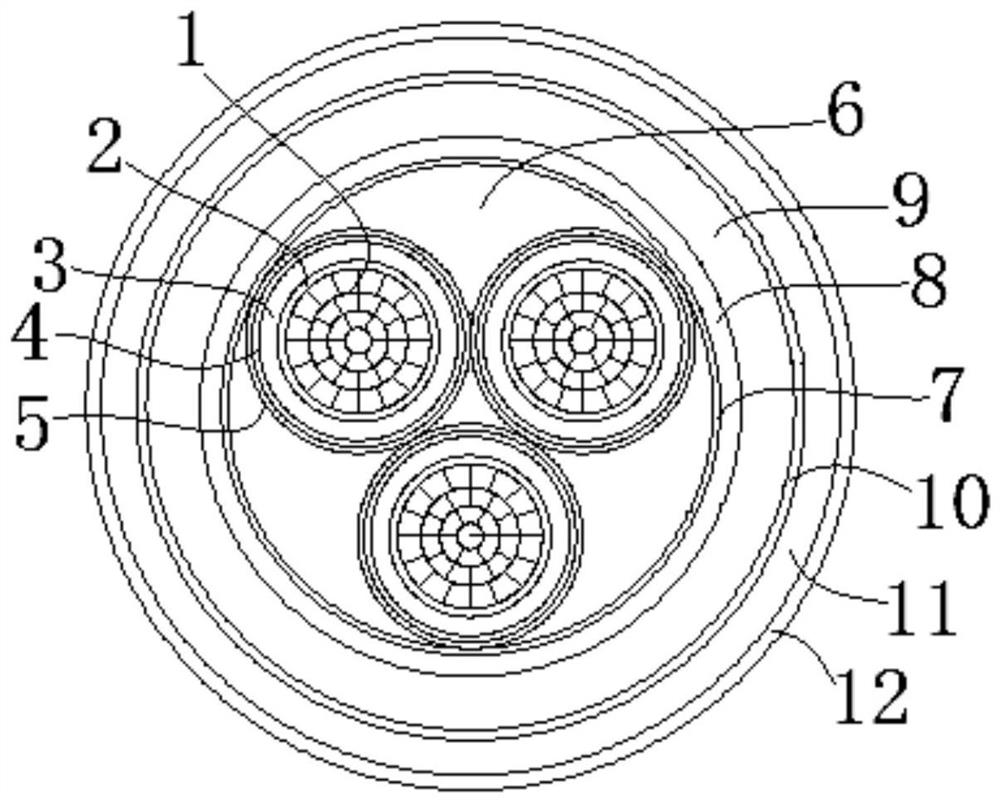

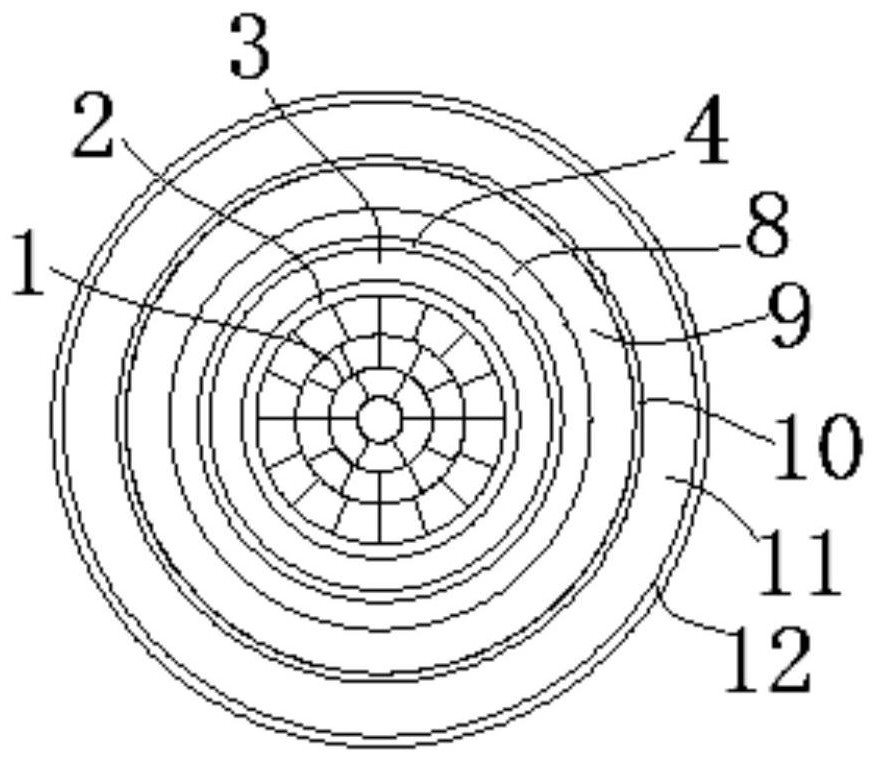

[0048] see figure 1 As shown, the present invention includes an insulating structural cable core, and the exterior of the insulating structural cable core is sequentially coated with a metal isolation layer 8, a fireproof cooling layer 9, an outer wrapping layer 10 and a fireproof sheath layer from the inside to the outside.

[0049] Wherein, the insulating structure cable core is a stranded structure of three insulated conductors, and the stranded gaps of these insulated conductors are filled with non-hygroscopic materials—such as filling layers 6 of polyolefin materials, and the insulated conductors and filling layers 6 of these stranded structures It is tightly formed by the inner tape layer 7 which is wrapped two layers (or three layers; the thickness is about 0.2mm). The inner tape layer 7 is a halogen-free, low-smoke, flame-retardant glass fiber tape wrapping structure. Each of the aforementioned insulated conductors is mainly composed of a conductor 1 and an inner semic...

Embodiment 2

[0074] Other contents of this embodiment are the same as those of Embodiment 1, except that the conductor is made of aluminum, that is, an aluminum conductor.

Embodiment 3

[0076] Other contents of this embodiment are the same as those of Embodiment 1, except that the conductor is made of aluminum alloy, that is, the aluminum alloy conductor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com