Method for increasing response speed of flying shear

A technology of response speed and flying shear, which is applied in the field of metallurgical rolling, can solve problems such as piled steel accidents and flying shears not responding well, and achieve the effects of ensuring timeliness, improving response speed, and shortening the action cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

[0037] Example:

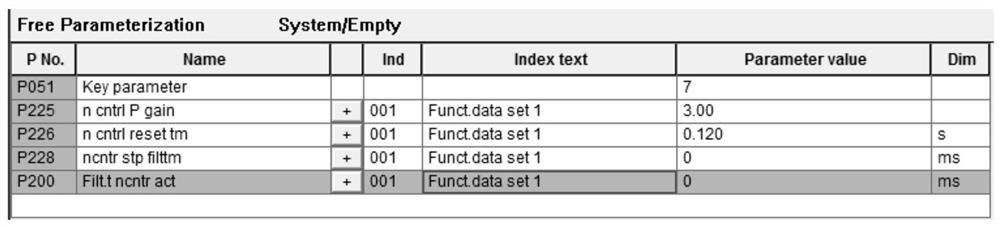

[0038] In this embodiment, it is achieved through the joint action of several measures for rolling a steel bar 2# flying shear. During the implementation of the embodiment, continuous debugging is required to achieve the target effect. This embodiment adopts Siemens STEP software and 6RA7025 DC speed control device. Including the following measures:

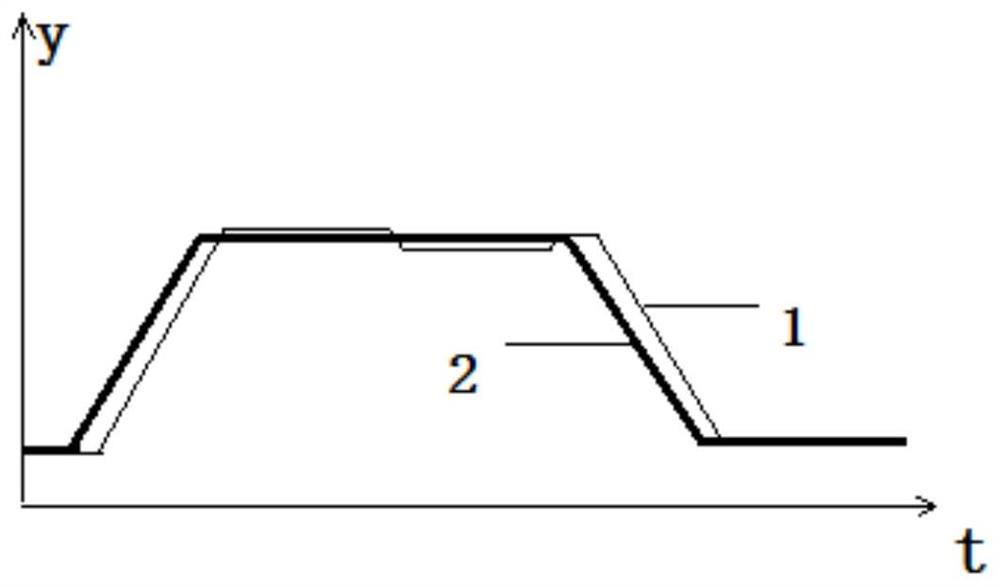

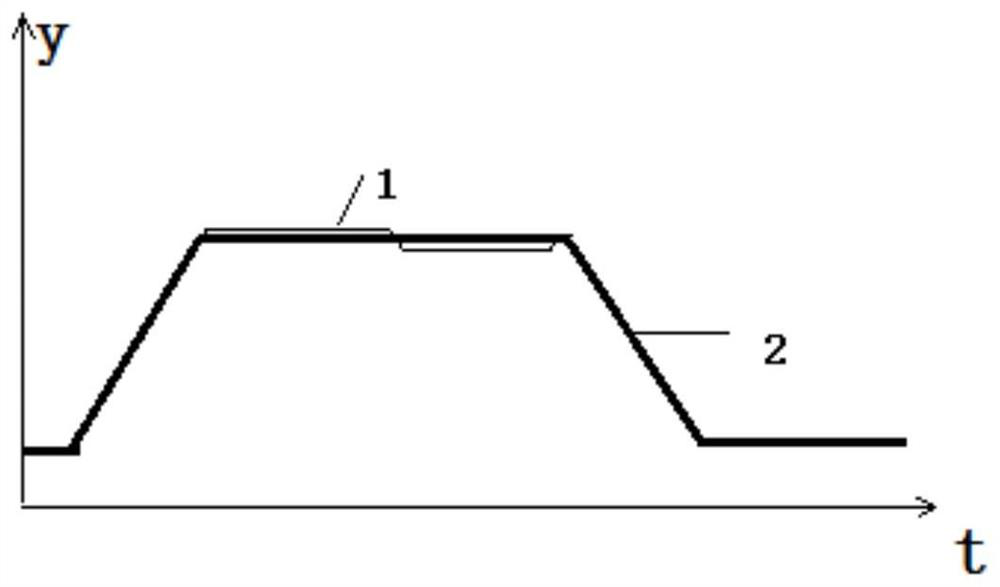

[0039] A. If Figure 5 As shown, the thermal detection signal of the flying shear is changed from the previous level signal to the edge signal by using the rising edge command in the Siemens STEP software. The edge signal is also called a pulse signal. The difference between a pulse signal and a level signal is that the signal intercepted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com