Defect positioning method based on laser ultrasonic B scanning

A laser ultrasonic and defect technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and processing response signals of detection, etc. It can solve the position, shape and size of defects that cannot be intuitively reflected. and other problems, to achieve the effect of highlighting defect signal characteristics, intuitive expression, and improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

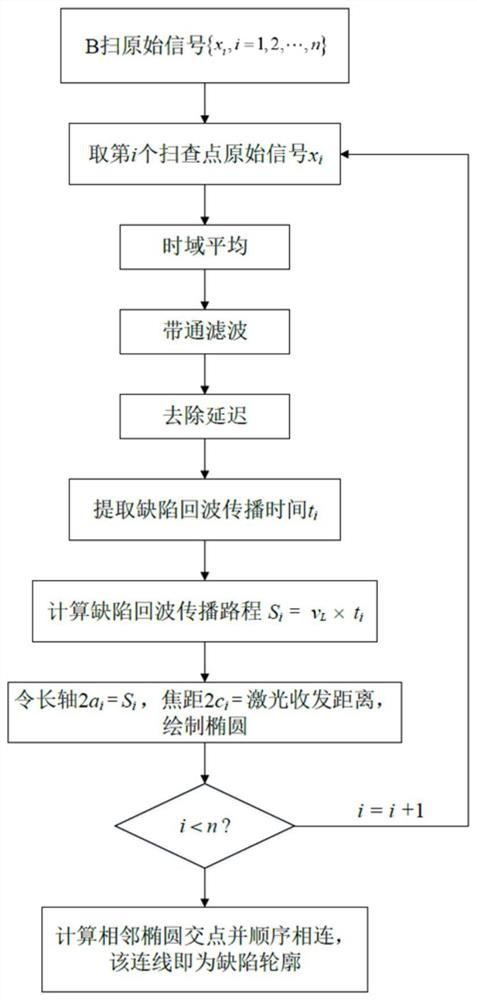

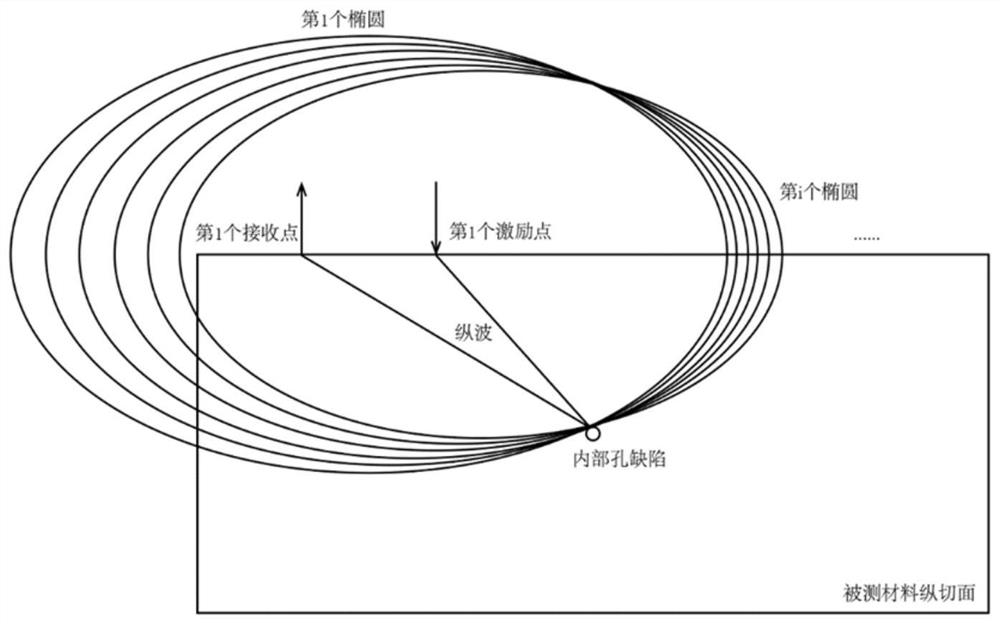

[0033] The defect location method based on the laser ultrasonic B-scan of the present invention reconstructs the B-scan signal into an image, and uses the longitudinal wave to detect the internal defect of the material through the B-scan method. Such as figure 1 As shown, it includes seven parts, which are B-scan, signal processing, extraction of echo peak time, calculation of echo propagation distance, drawing of ellipse, calculation of adjacent ellipse intersection and output image, as follows.

[0034] 1) B-scan

[0035] B-scanning is performed on the upper surface of the aluminum material by moving the excitation laser and the receiving laser at equal intervals at the same time to obtain B-scan signals, and multiple excitations and receptions are performed at each scanning point.

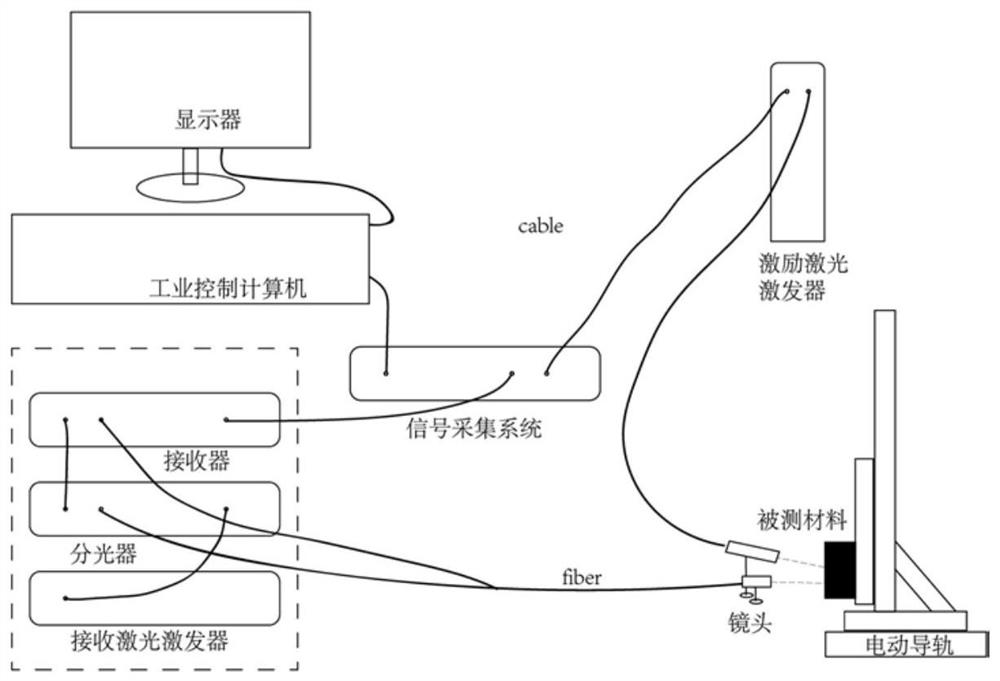

[0036] Specifically, with the help of the existing laser ultrasonic detection pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com