Intermediate infrared glass metal melt-sealed heat collecting tube

A technology of infrared glass and heat collecting tube, which is applied in the directions of solar collector, solar collector safety, solar collector controller, etc. Emit heat loss, reduce adhesion, and improve the effect of effective heat gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

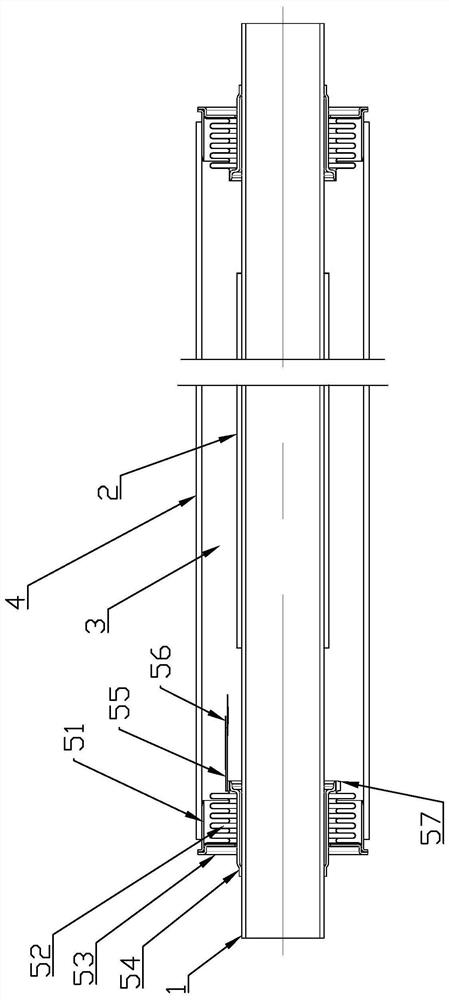

[0032] Such as figure 1 As shown, a kind of mid-infrared glass metal fusion-sealed heat collecting tube provided by the present invention comprises:

[0033] A steel pipe 1, in which the fluid to be heated circulates, and a selective absorption coating structure 2 is provided on the outer wall, and the selective absorption coating structure 2 can convert the received solar energy into heat and transfer it to the fluid to be heated;

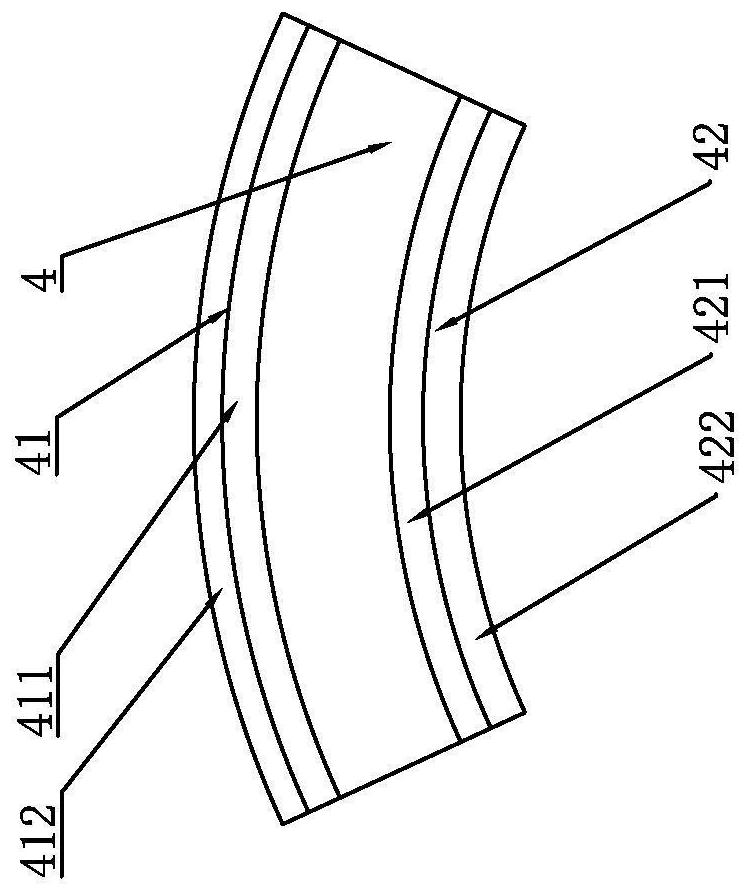

[0034] The cover glass tube 4 is coaxially arranged on the outside of the steel pipe 1, and the two ends of the cover glass tube 4 are respectively welded and connected to a Kovar alloy sleeve 51, and each of the Kovar alloy sleeves 51 is connected to the outer end of a bellows 52. The end cap 43 is sealed and connected, and the inner end of the bellows 52 is sealed and connected with a support ring 54, and the support ring 54 is sealed and fixed (for example welded) on the outer wall of the steel pipe 1; when the steel pipe 1 and the cover glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com