Device for transforming compressed air pipeline in ship industry and transforming method

A compressed air pipeline, compressed air technology, applied in valve heating/cooling device, valve device, pipeline protection and other directions, can solve the problems of complex structure of compressed air water removal device, poor removal of moisture and impurities, etc. The effect of high water removal efficiency, improved maintainability, and enhanced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

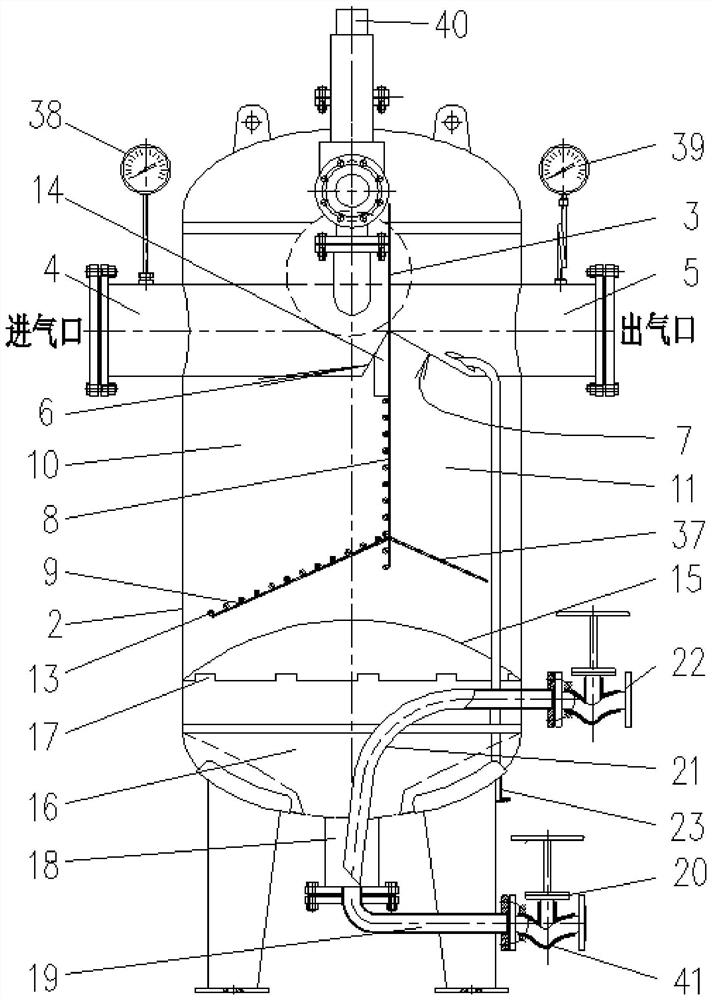

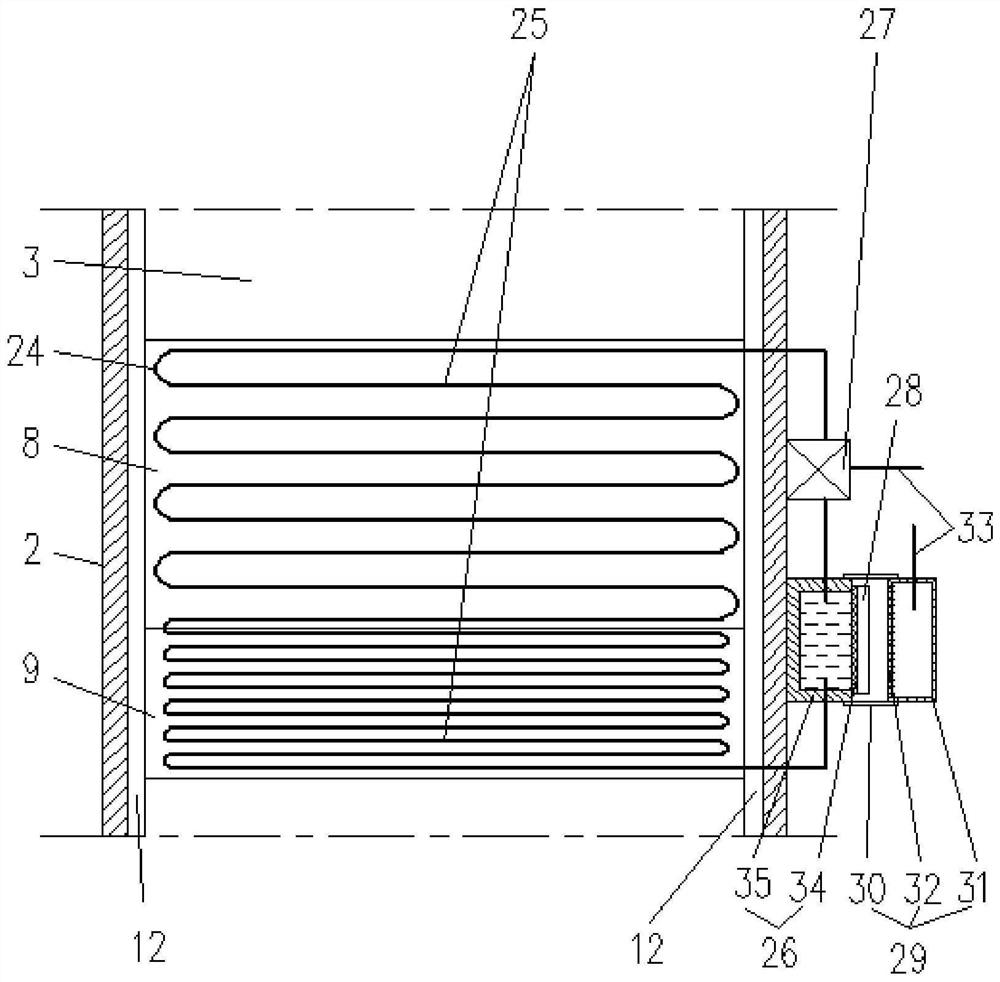

[0041] Such as Figures 1 to 6 Shown is an embodiment of a device for the transformation of compressed air pipelines in the shipbuilding industry, including a compressed air automatic separation device 1 for water accumulation and sedimentation. The partition plate 3 in the tank body 2, the air inlet pipe 4 and the air outlet pipe 5 inserted into the tank body 2 and separated on both sides of the partition plate 3, the air inlet pipe 4 is inserted into the tank body 2 is connected to one side of the partition plate 3, and one end of the outlet pipe 5 inserted into the tank body 2 is connected to the other side of the partition plate 3, and the inlet pipe 4 The lower part of the connection between the upper part and the partition plate 3 is provided with a first oblique cutout 6, and compressed air is formed between the first oblique cutout 6 and the partition board 3 and enters the tank body 2 from the air intake pipe 4. In the gas inlet port, a second oblique slit 7 is provi...

Embodiment 2

[0054] A compressed air pipeline transformation method using the device for the transformation of compressed air pipelines in the shipbuilding industry according to Embodiment 1 includes installing a compressed air water accumulation and sedimentation automatic separation device 1 in series on the pipeline of the compressed air terminal.

[0055] Preferably, a decontamination device 42 can also be installed in series on the pipeline of the compressed air terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com