A wall-mounted spray dust suppression treatment device for coal mine underground operations

A spray dust reduction and processing device technology, which is applied in mining devices, spray devices, safety devices, etc., can solve the problems of not being able to meet all-round dust removal, not having the function of angle adjustment, wasting space, etc., to achieve improved dust removal effect and simple design , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments.

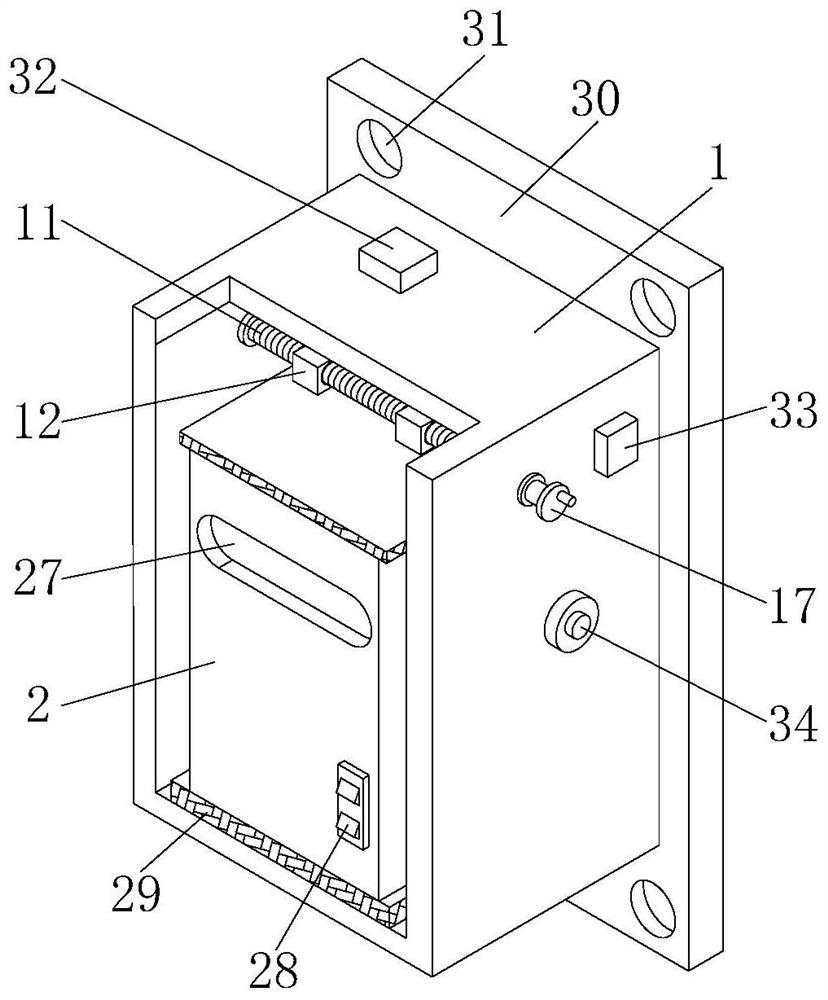

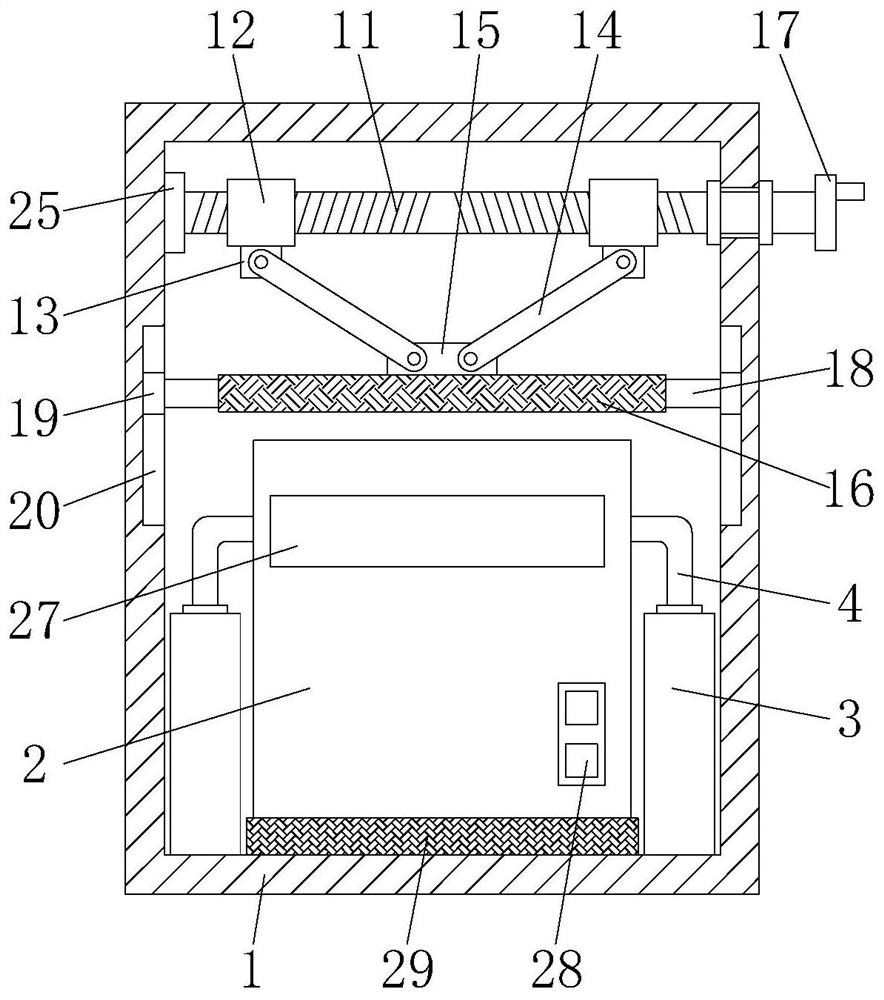

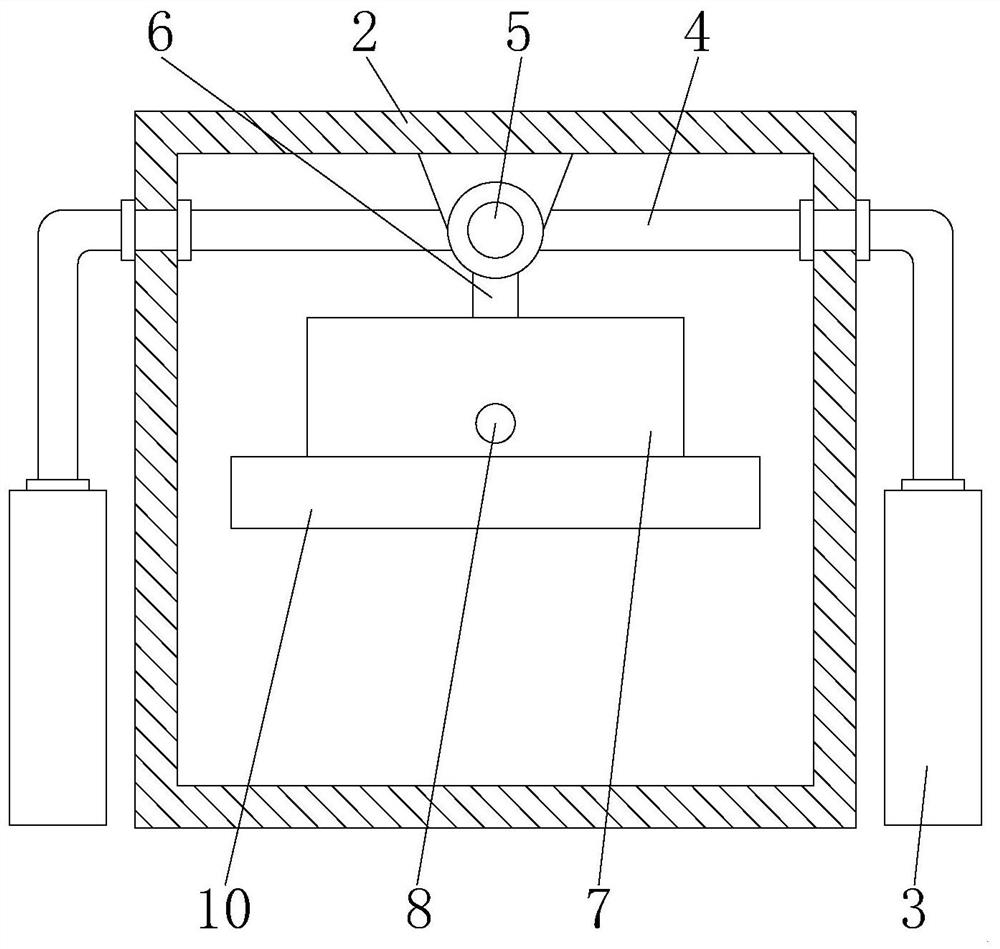

[0034] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 ,in figure 1 It is a schematic structural diagram of a preferred embodiment of a wall-mounted spray dust-reducing treatment device for underground operations in coal mines provided by the present invention; figure 2 for figure 1 Shown is the schematic diagram of the internal structure of the installation box of the wall-mounted spray dust-reducing treatment device for underground operations in coal mines; image 3 for figure 2 The front view of the internal structure of the dust suppression box of the wall-mounted spray dust suppression treatment device for underground operations in the coal mine is shown; Figure 4 for figure 2 The side view of the internal structure of the dust suppression box of the wall-mounted spray dust suppression t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com