Cold-rolled silicon steel thin strip continuous annealing production line deviation rectifying device and method

A technology of cold-rolled silicon steel and deflection correction device, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as inability to generate large friction between the deflection correction roller and the strip steel, insufficient deflection correction capability, edge scraping, and broken belts, etc., to achieve Significant deviation correction effect, fast response time, and large deviation correction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

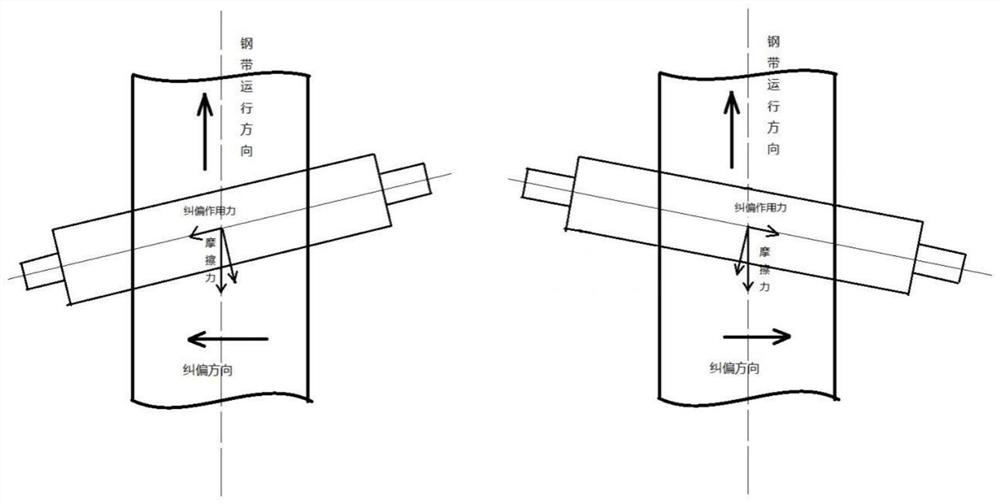

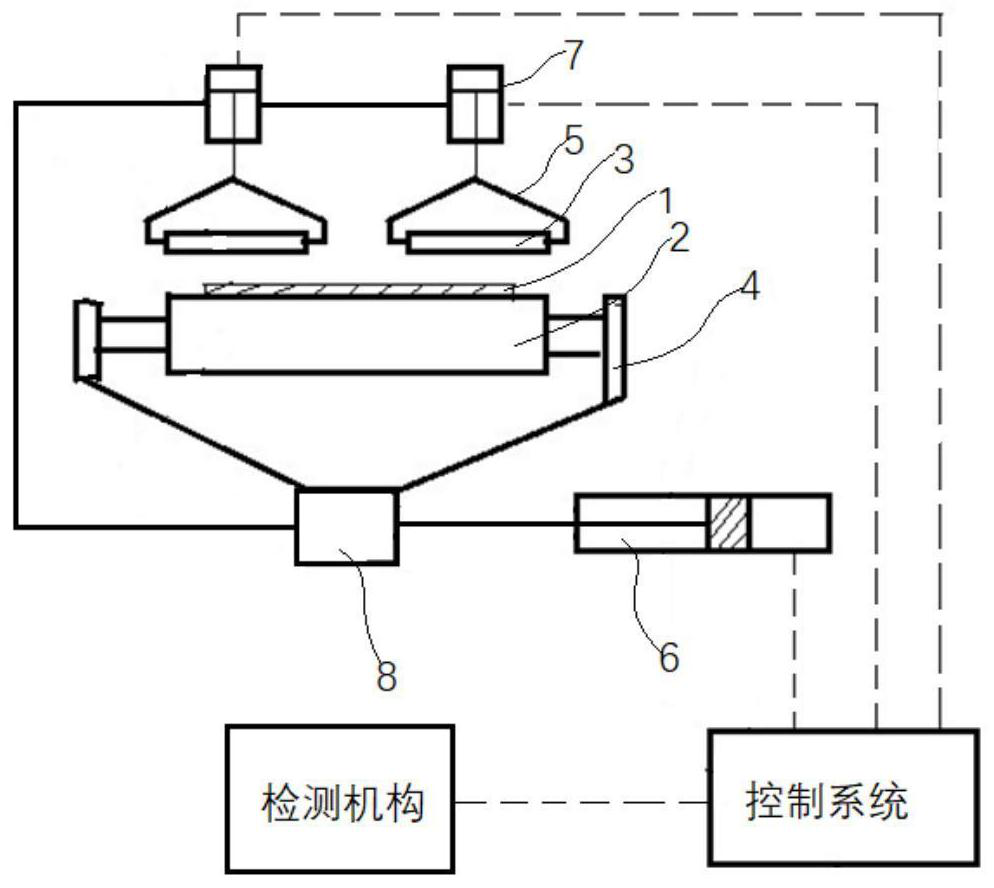

[0023] like figure 2 and image 3 As shown, a deviation correction device for a continuous annealing production line of cold-rolled silicon steel thin strip includes a control system and several deviation correction units distributed along the running direction of strip steel 1; The detection mechanism, the correction roller 2 located under the strip steel 1 for applying a correction force to the strip steel 1, the swing mechanism that can drive the deviation correction roller 2 to swing left and right relative to the strip steel 1 on the horizontal plane; for the most downstream correction unit, it also includes distribution The pinch rollers 3 on the working side and the transmission side above the strip steel 1 can drive the one-to-one corresponding pinch rollers 3 to press down on the strip steel 1. The pressing mechanism can be driven by the swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com