Intelligent logistics transportation system

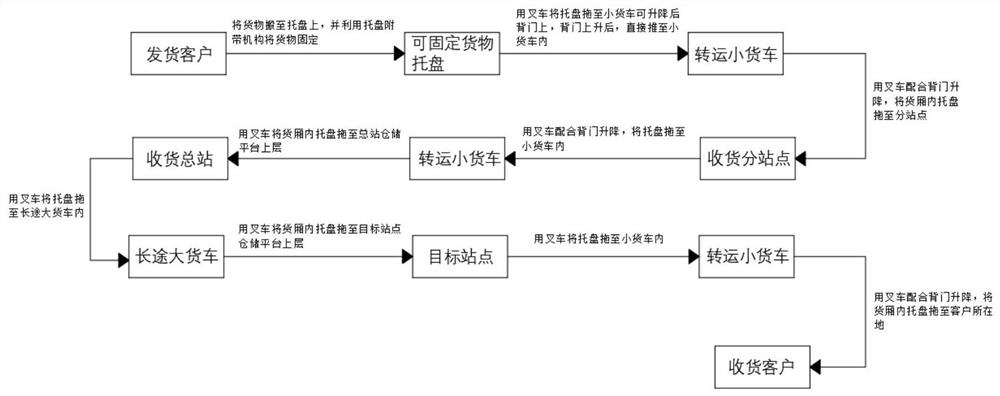

A transportation system and intelligent logistics technology, applied in transportation and packaging, conveyors, lifting devices, etc., can solve the problems of time-consuming and labor-intensive loading and unloading, chaotic cargo stacking, and high operating costs, saving time and reducing cargo damage. , the effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

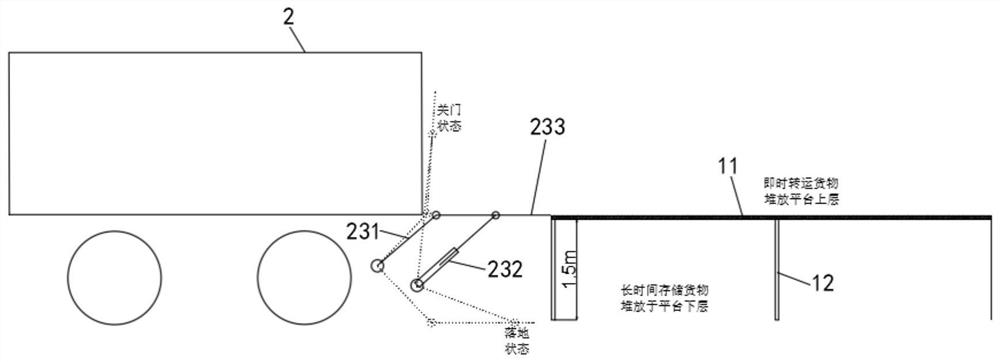

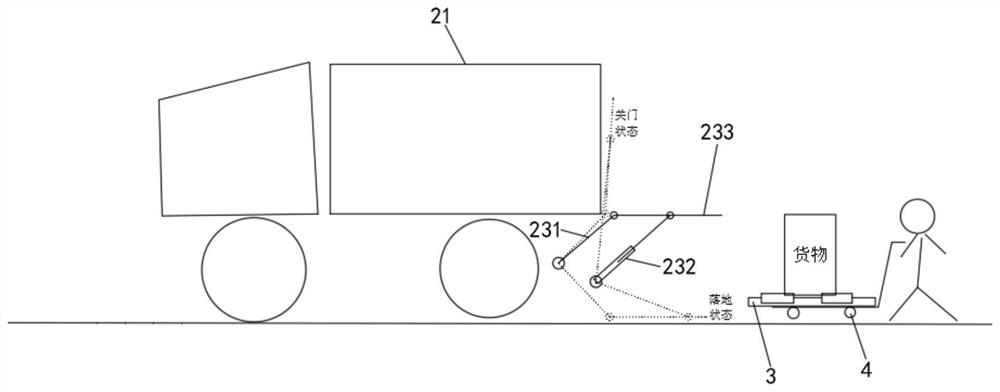

[0038] refer to Figure 1-6, an intelligent logistics transportation system, including a layered storage platform 1, an intelligent logistics vehicle 2, a fixed cargo pallet 3 and a manual hydraulic forklift 4, the layered storage platform 1 is composed of a steel frame main body 11 and a platform support column 12, and the intelligent logistics vehicle 2 includes a small transfer truck 21 and a large long-distance truck 22. The small transfer truck 21 is equipped with a liftable rear door 23. With the cooperation of the manual hydraulic forklift 4, one person can complete loading and unloading. When the liftable back door 23 is on the ground, the person pushes the fixed cargo pallet 3 with the goods onto the liftable back door 23 through the manual hydraulic forklift 4, and the liftable back door 23 rises to be flush with the compartment of the transfer truck 21 , people can push the goods into the compartment of the transfer truck 21. In addition, the long-distance large tru...

Embodiment 2

[0055] refer to Figure 7 In this embodiment, the fixed goods pallet 3 can be replaced by the flexible fixing method in the first embodiment with a rigid fixed goods method, that is, the reel 32 and the wide-band rope 33 in the first embodiment are connected by an externally threaded screw 34 and an internally threaded sleeve 35 to replace.

[0056] In this embodiment, the base 31 is surrounded by an internally threaded sleeve 35 and an externally threaded screw 34, so that the goods on the fixed cargo pallet 3 can be fixed, and the height can be adjusted by rotating the internally threaded sleeve 35.

Embodiment 3

[0058] refer to Figure 8 In this embodiment, the motor 247 is replaced by a portable screw screw machine 248 .

[0059] In this embodiment, the end of the screw rod 241 reserves an opening for docking with the portable screw-twisting machine 248, and the portable screw-twisting machine 248 is connected to the screw rod 241 and started to realize the lifting of the lifting platform 24. In this way, there is no need to add additional electrical systems in the compartment, and the lifting structure is simpler, which is convenient for maintenance and management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com