Drive motor controller discharge support circuit, control method and motor controller

A technology for driving motors and controllers, applied in the field of motor controllers and driving motor controller discharge support circuits, to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

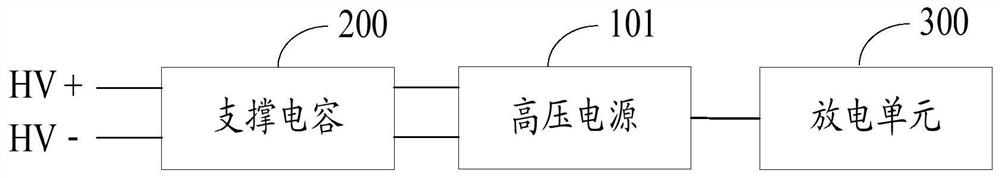

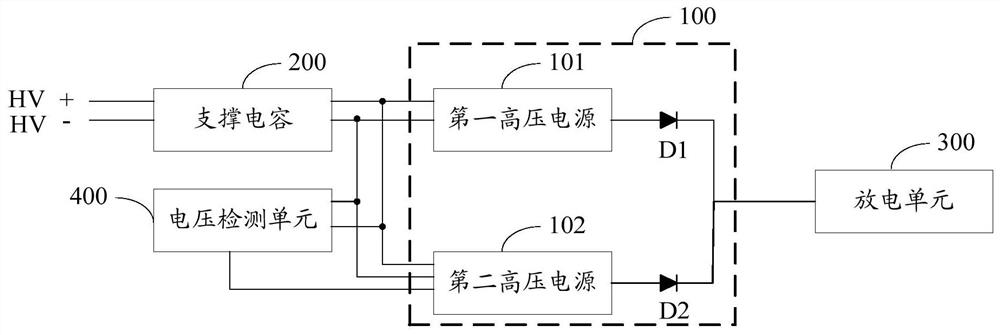

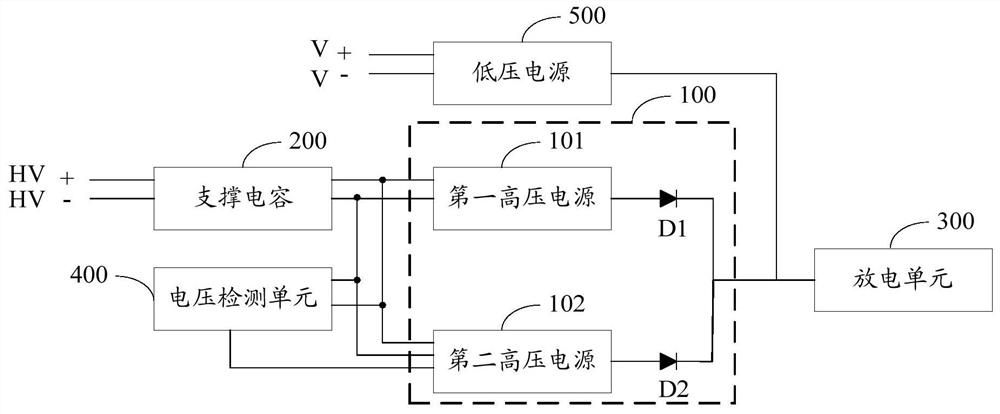

[0040] An embodiment of the present invention provides a drive motor controller discharge support circuit, refer to figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the discharge support circuit of the drive motor controller of the present invention.

[0041] The discharge support circuit of the drive motor controller includes: a support capacitor 200, a high-voltage power supply unit 100, and a discharge unit 300; wherein, the input end of the support capacitor 200 is connected to the high-voltage power supply terminal HV, and the output end of the support capacitor 200 is connected to the high-voltage power supply terminal HV. The input terminal of the high voltage power supply unit 100 is connected, and the output terminal of the high voltage power supply unit 100 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com