Intelligent vertical mill production process and device for aggregates

A technology of production equipment and feeding equipment, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of poor production environment, scattered equipment, large investment in environmental protection, etc., to avoid large occupied area and system intensification , the effect of investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The application will be further described below in conjunction with the drawings and embodiments.

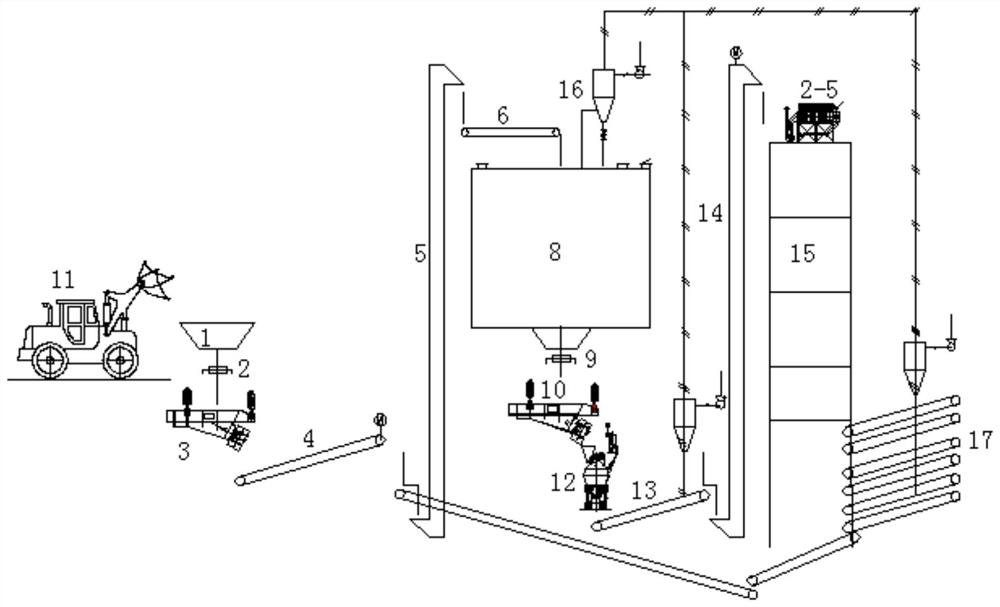

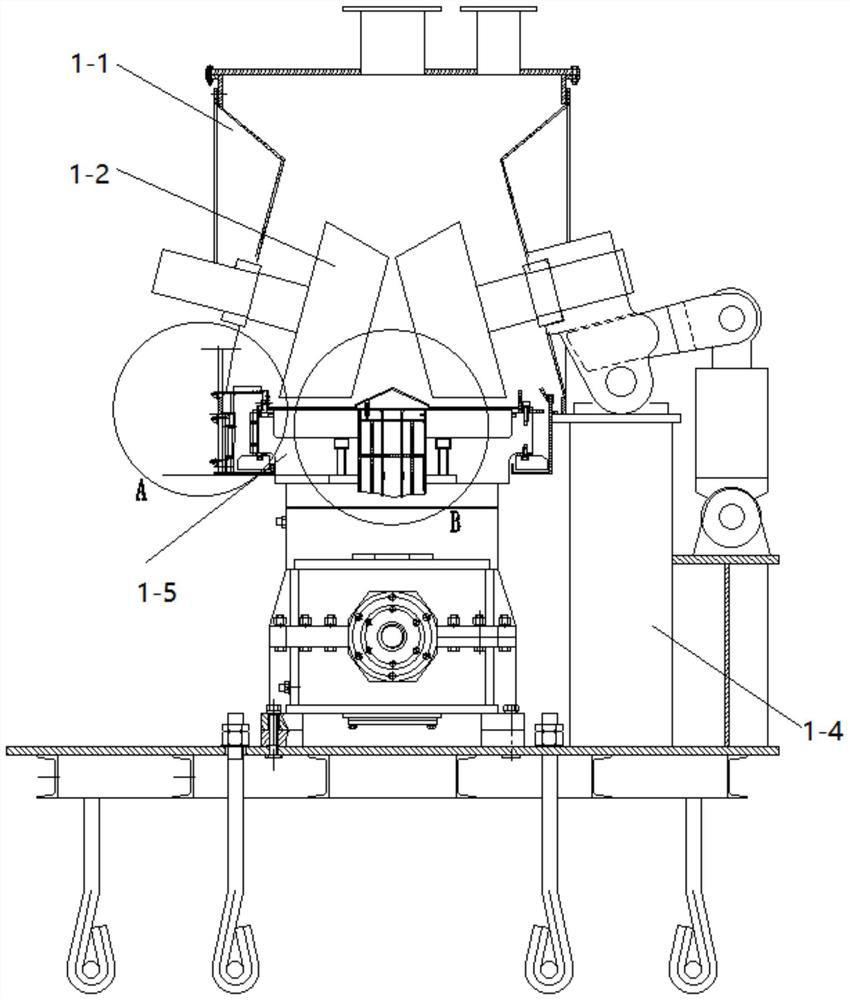

[0045] Such as Figure 1-Figure 7 As shown, the intelligent vertical mill production device for aggregate includes:

[0046] The first feeding device, the first feeding device is used to send raw materials such as sand and gravel to the intelligent vertical mill device; the second feeding device, the second feeding device is used to send machine-made aggregates to the three-dimensional module In the chemical screening building device; the intelligent vertical mill device 12, the intelligent vertical mill device is arranged between the first feeding device and the second feeding device, and the intelligent vertical mill device is used to use raw materials such as sand and gravel Grind into machine-made aggregate; three-dimensional modular screening building device 15, the second feeding device is between the three-dimensional modular screening building device and the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com