Efficient energy-saving type tobacco drying system

A drying system and energy-saving technology, applied in the field of tobacco drying, can solve the problems of poor drying effect, high energy consumption, general energy-saving and environmental protection performance, etc., and achieve the effect of fast drying speed, small thermal inertia and good heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

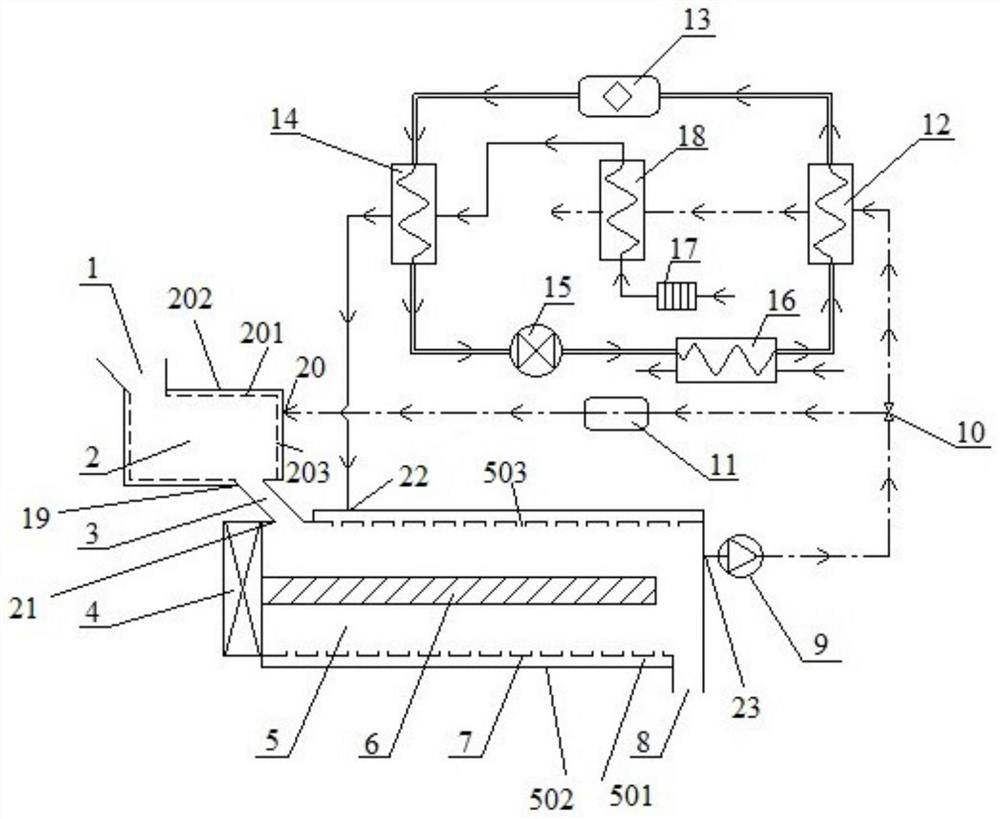

[0025] like figure 1 As shown, a high-efficiency and energy-saving tobacco drying system, the drying system includes a preheating drying box 2, an infrared drying drum 5, a heat pump cycle module, an air filter 17, an air preheater 18, an air pump 9, a three-way valve 10 and The high temperature dehumidifier 11, the heat pump circulation module includes a waste heat source evaporator 12, a compressor 13, a condenser 14, an expansion valve 15 and an air source evaporator 16 connected end to end in sequence to form a circuit, and the preheating drying box 2 is connected to the infrared drying drum 5 The air filter 17, the air preheater 18, the condenser 14, the infrared drying drum 5, the suction pump 9, the three-way valve 11, the waste heat source evaporator 12 and the air preheater 18 are connected in sequence, and the three-way valve 11 One interface is also connected with the high temperature dehumidifier 11, and the high temperature dehumidifier 11 is connected with the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com