A cable head processing table

A technology of processing table and cable head, which is applied in the direction of equipment for connecting/terminating cables, etc., can solve the problems of no reasonable tool and cable head accessories storage location, low stability of cable head process, affecting work efficiency, etc., to improve convenience High performance, ensuring folding stability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

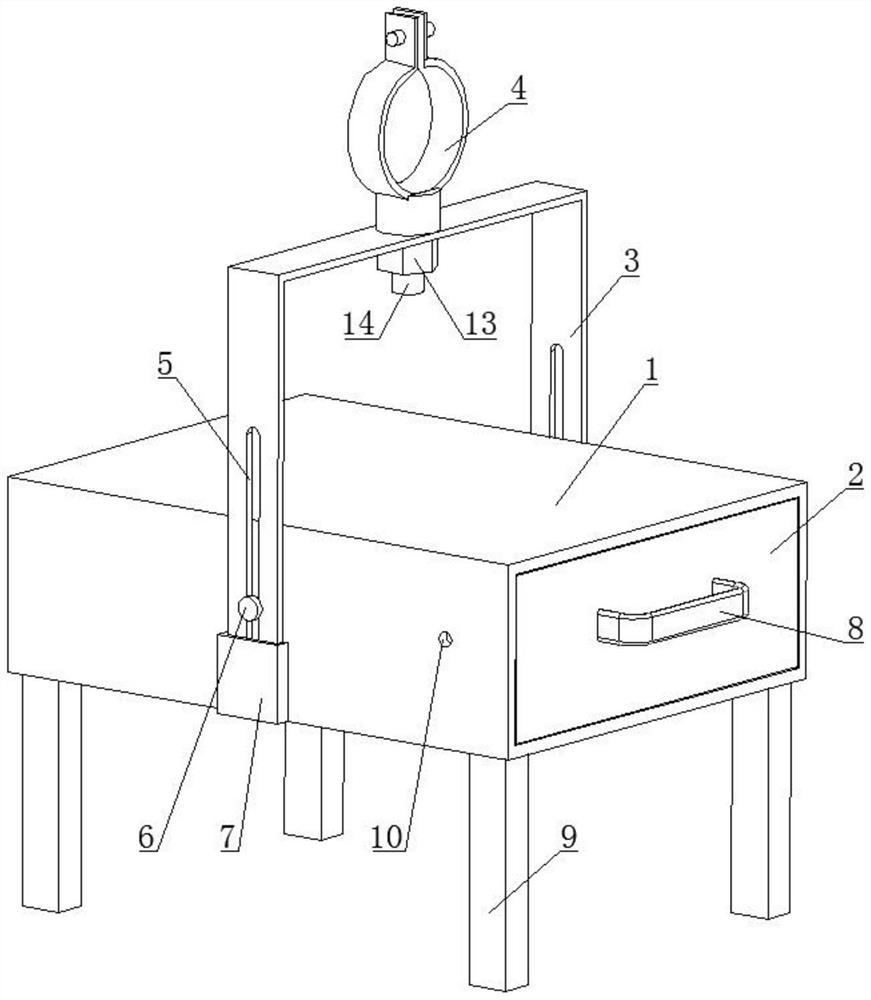

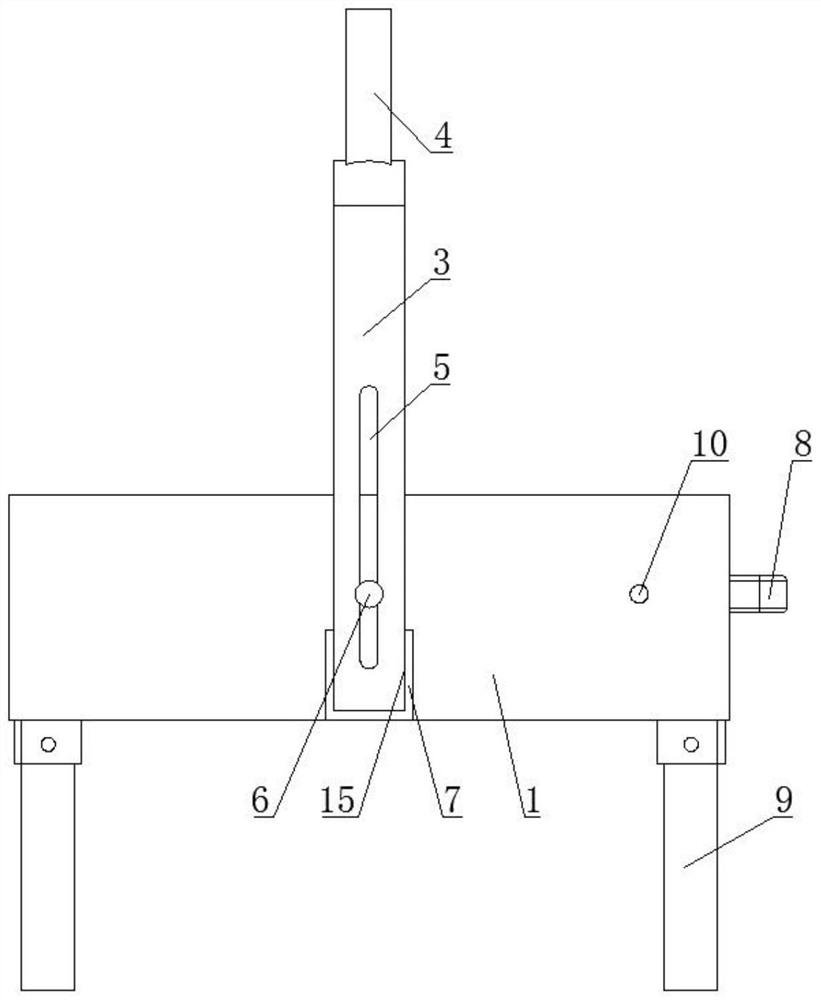

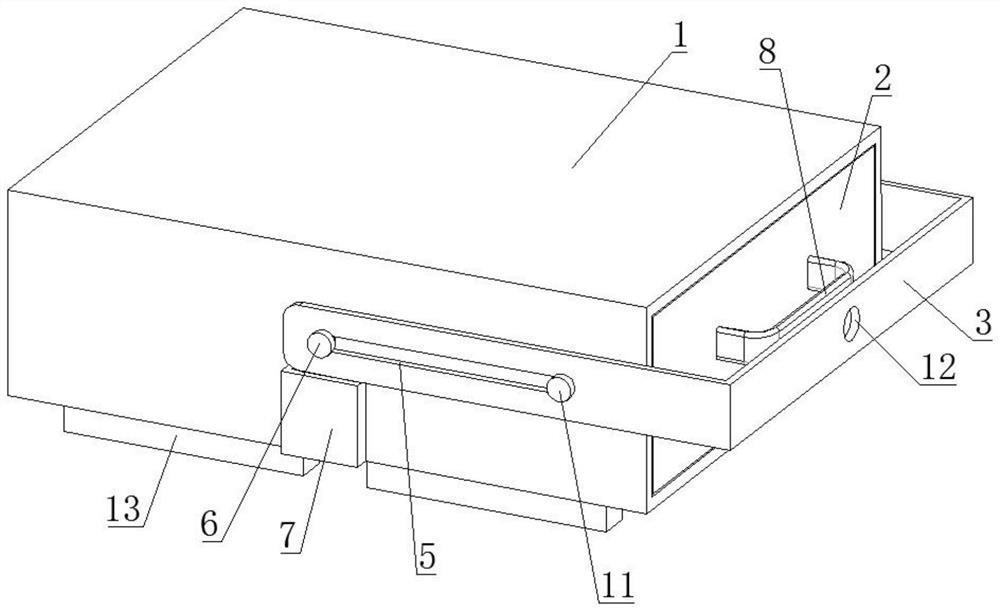

[0026] As shown in the drawings, a cable head processing table includes a storage case 1, a U-shaped support frame 3 and a hoop 4, and the support frame 3 includes a bottom frame and side frames on both sides; the support frame The side frames of 3 are provided with elongated guide holes 5, and the left and right sides of the storage housing 1 are provided with positioning pins 6 that pass through the guide holes 5, and the width of the guide holes 5 is larger than that of the positioning pins 6. Diameter, the guide hole 5 can be guided and slid through the positioning pin 6; the lower side of the positioning pin 6 is provided with a limit block 7, and the limit block 7 is provided with a slot 15, and the slot 15 is paired with the support frame. 3's side frames engage and limit; the hoop 4 is detachably mounted on the bottom frame of the support frame 3.

[0027] The support frame 3 rotates and slides on the positioning pin 6, and is vertically inserted into the slot 15. Thro...

Embodiment 2

[0037] The basic structure of this embodiment is the same as that of Embodiment 1, and the difference is that the slot 15 is a through groove with upper and lower openings. The side frame of the support frame 3 is fully inserted into the through groove, and the upper part of the guide hole 5 is supported by the positioning pin 6 on the upper part, so that the operation stability is better.

[0038] The cable head processing table has a simple structure and is convenient to use. The support frame rotates and slides on the positioning pin, and is inserted vertically into the slot. The hoop clamps and fixes the cable, and a single person can make the cable head, which saves labor, reduces labor intensity, can effectively fix the cable firmly, and ensures the quality and efficiency of making the cable head; Pull out and rotate, pass the limit pin through the guide hole and fix it with the limit hole, limit the position of the support frame, ensure the folding stability of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com