Preparation method and application of an activated compatibilizer for repairing failed lead-acid batteries

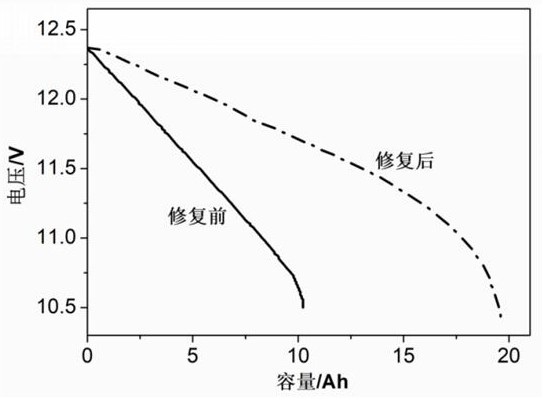

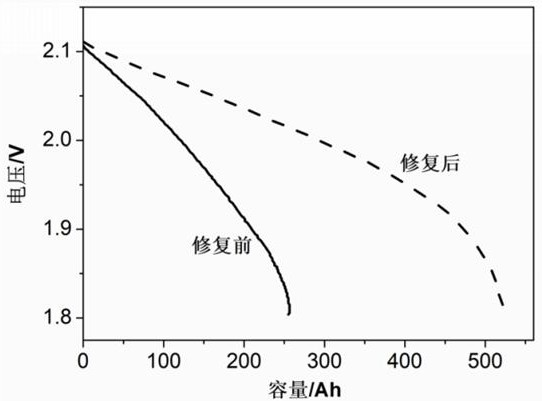

A technology of lead-acid batteries and compatibilizers, which is applied in the direction of lead-acid batteries, secondary battery repair/maintenance, electrolyte/reactant regeneration, etc. It can solve the problems of inability to deeply utilize porous carbon channels, short discharge time, and long repair time And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

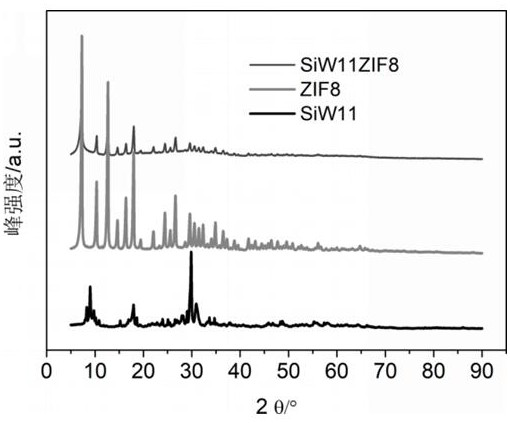

[0035] Example 1 Nano activator SiW 11 Preparation method of @ZIF-8:

[0036] 1. Precursor K 8 [SiW 11 o 39 ]∙14H 2 O (abbreviated as SiW 11 ) Synthesis:

[0037] Dissolve 18.2 g of sodium tungstate in 30 mL of water, and add 16.5 mL of HCl (4 mol∙L -1 ). Then add 10 mL sodium silicate aqueous solution (containing 1.1 g sodium silicate) to the above solution, pass through 4 mol∙L -1 Adjust the pH of the solution to 5-6 with hydrochloric acid (the amount of hydrochloric acid added is about 4 mL). After continuing to stir for 100 min, 9 g of potassium chloride was added, and after continuing to stir for 15 min, the crude product was obtained by filtration.

[0038] Dissolve the crude product in 85mL of water, filter to remove insoluble matter, then add 8g of potassium chloride to the filtrate, filter the resulting white solid with suction, and use 2 mol∙L -1 Potassium chloride 10mL was washed twice, and air-dried; the purified product SiW was obtained 11 , the purifie...

Embodiment 2

[0044] Example 2 An activated compatibilizer for repairing failed lead-acid batteries

[0045] A kind of formula composition of the activated compatibilizer used for repairing the failed lead-acid battery is: Nano activator SiW 11 @ZIF-8 15.0 g, PEG2000 12.5 g, ammonium acetate 6.9 g, zinc sulfate 23.5 g, magnesium sulfate 7.8 g, sodium sulfate 23.3 g, aluminum sulfate 3.5 g, potassium sulfate 11.2 g, ammonium sulfate 7.5 g, sorbitol 7.4 g , Tetramethylammonium chloride 2.1 g.

[0046] A preparation method of an activated compatibilizer for repairing a failed lead-acid battery:

[0047] Weigh 15.0g nanometer activator SiW 11 @ZIF-8, spare.

[0048] Prepare an aqueous solution containing 6.9 g of ammonium acetate and 12.5 g of polyethylene glycol (PEG2000), marked as solution A;

[0049] Heat the solution A to raise the temperature, when the temperature rises to 40°C, the nano-activator SiW 11 @ZIF-8 was slowly added to solution A in batches, and stirred at a uniform speed...

Embodiment 3

[0053] Example 3 An activated compatibilizer for repairing failed lead-acid batteries

[0054] A kind of formula composition of the activated compatibilizer used for repairing the failed lead-acid storage is: Nano activator SiW 11 @ZIF-8 15.0 g, PEG2000 15.0 g, ammonium acetate 8.5 g, zinc sulfate 22.3 g, magnesium sulfate 7.8 g, sodium sulfate 14.1 g, aluminum sulfate 2.3 g, potassium sulfate 14.2 g, ammonium sulfate 6.3 g, sorbitol 15.0 g, Tetramethylammonium chloride 3.0 g.

[0055] A preparation method of an activated compatibilizer for repairing a failed lead-acid battery:

[0056] Weigh 15.0g nanometer activator SiW 11 @ZIF-8, spare.

[0057] Prepare an aqueous solution containing 8.5g ammonium acetate and 15.0g polyethylene glycol (PEG2000), marked as solution A;

[0058] Heat the solution A to raise the temperature, when the temperature rises to 40°C, the nano-activator SiW 11 @ZIF-8 was slowly added to solution A in batches, and stirred at an even speed for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com