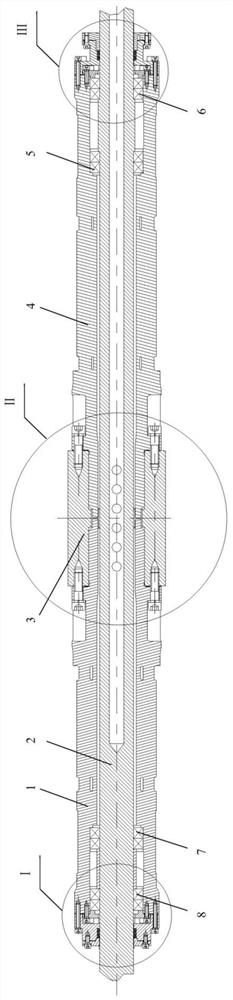

A balance force-measuring device for the test of transverse jet flow effect with high-pressure seal

A high-pressure sealing and force measuring device technology, which is used in measuring devices, aerodynamic tests, and testing of machine/structural components, etc. It can solve the problem of increasing the structural design complexity of the balance calibration device, and the work intensity of the balance calibration, and the inability to simulate the jet flow of the aircraft. effect, inability to obtain pneumatic data, etc., to achieve the effect of improving the level of refined development, improving measurement accuracy, and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

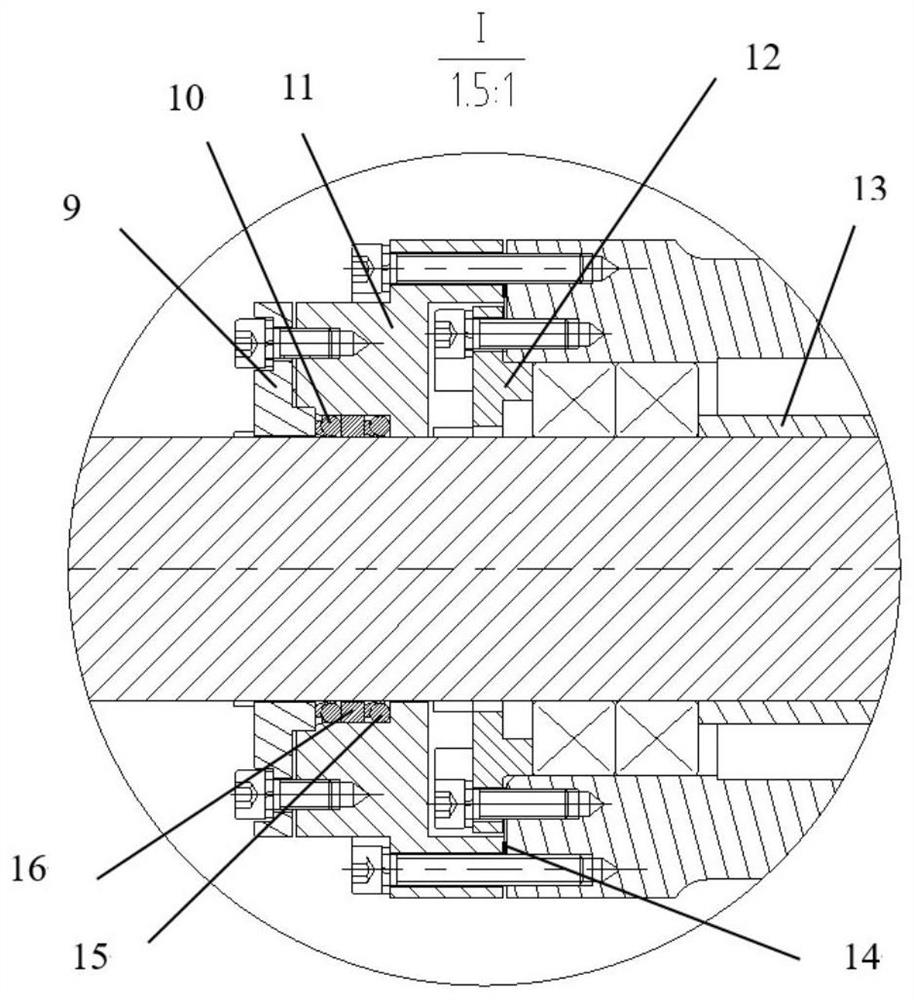

[0081] The installation process of the balance force-measuring device used for the high-pressure sealing transverse jet effect test of the present embodiment is as follows:

[0082] 1. Balance 1 before installation

[0083] The fixed end 27 of the front balance is matched with the support beam 3 through the cylindrical gap, the front balance 1 and the support beam 3 are fixedly connected by 12 M20 bolts, and the roll positioning between the front balance 1 and the support beam 3 is through the front balance positioning key I26 and the front balance. The balance positioning key II 31 is realized, and the transition section 28 end face of the front balance 1 is provided with a sealing groove for installing the front balance seal ring II 24, and the high-pressure static sealing problem between the front balance 1 and the support beam 3 is solved by means of end face sealing.

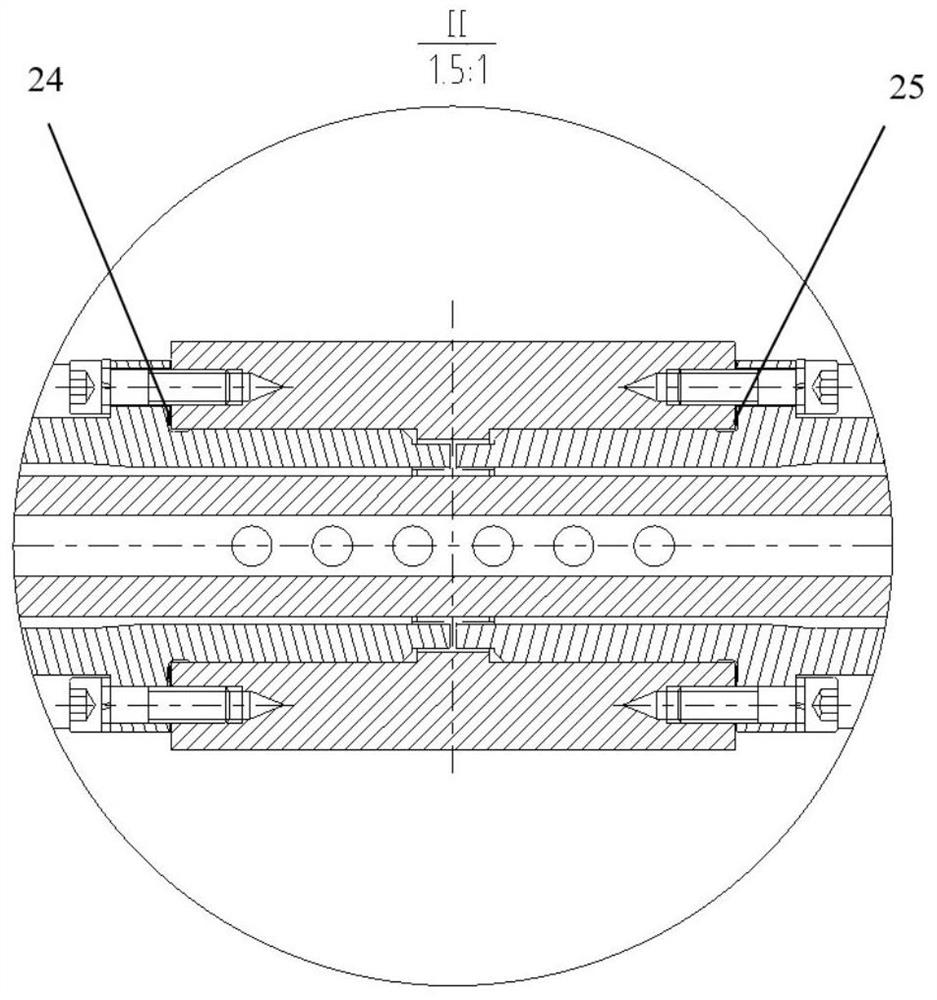

[0084] 2. Balance 4 after installation

[0085] The fixed end 41 of the rear balance is matched with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com