One-mold-time six-action thermal forming in-mold labeling, conveying and boxing production line and operation method

A one-time six-action heating and in-mold labeling technology, which is applied to household components, household appliances, and other household appliances, can solve the problem of declining market share of compressed air thermoforming containers, declining market share, and inability to use multiple functions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

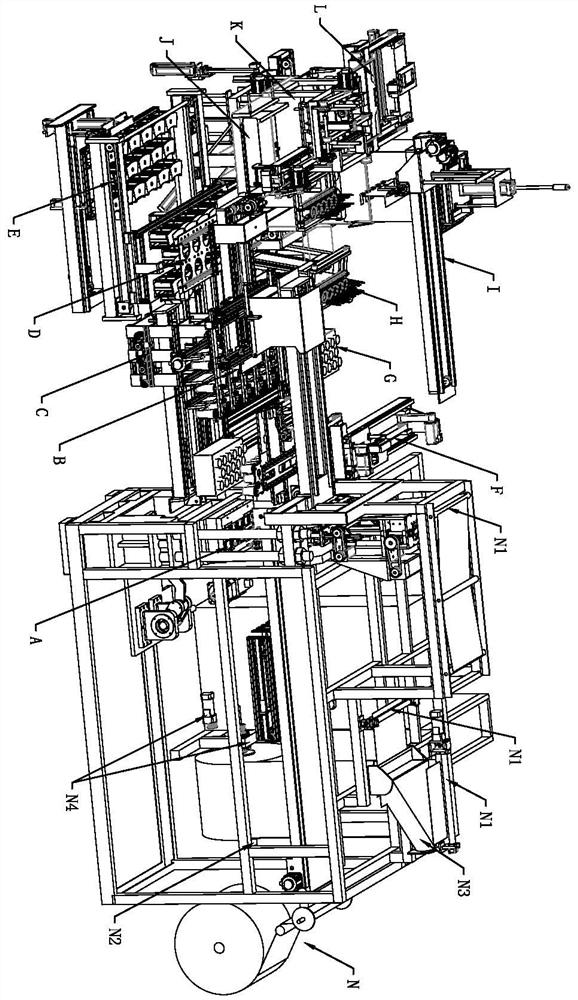

[0129]The one-time six-action thermoforming in-mold labeling, conveying and packing production line of this embodiment is provided with a cup making machine A and an in-mold labeling equipment group, the cup making machine is provided with a cup making machine driving group, and the cup making machine The driving group includes the lower mold lifting structure drive Q1, the lifting drive Q2, the top product bottom mechanism Q3, and the sheet feeding drive device Q4. These drives refer to the movement devices that can drive other equipment in the cup making machine. Among them, the cup-making driving group includes a lower mold lifting structure drive Q1, a lifting drive Q2, a top product bottom mechanism Q3, and a sheet-feeding drive device Q4, all of which can use the drive device that comes with the existing cup-making machine, which belongs to the prior art. Those skilled in the art should be able to clearly understand and implement. Among them, the lower mold lifting struc...

Embodiment 2

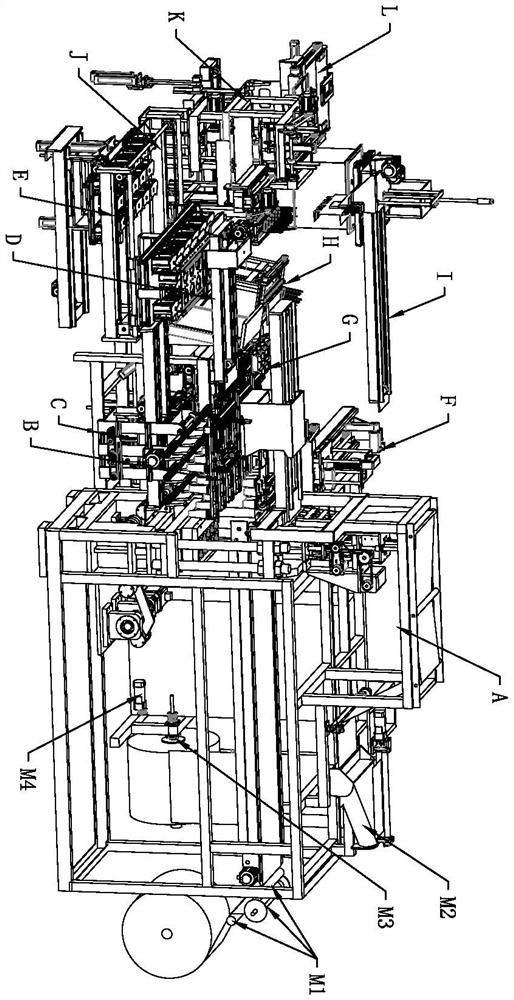

[0158] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the cup-making mold of the cup-making machine A includes an upper mold A-1 and a lower mold A-2, and the molding cavity of the upper mold A-1 corresponding to the lower mold A-2 is provided with a plurality of pulling die heads A-4, the pull-up rod A1-41 is installed on the pull-up connection plate A-5 and the pull-up connection plate A-5 is driven up and down by the pull-up drive Q2 device A-8, and the pull-up connection plate A-5 can also be fixed There is a cross arm, and the output end of the pull-up drive Q2 device A-8 is connected to the cross-arm A-81 and drives the cross-arm up and down. It is fixedly connected with the lifting connecting plate A-5, so as to realize the simultaneous lifting of multiple lifting rods A1-41. The lifting drive...

Embodiment 3

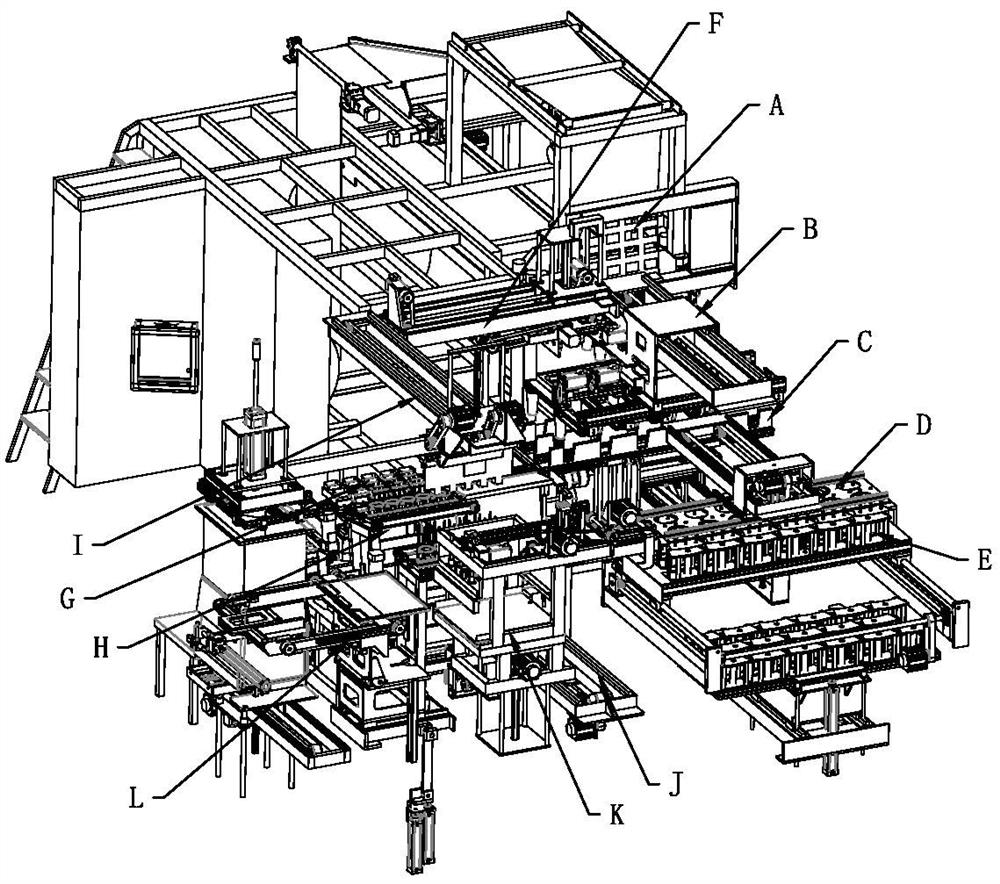

[0176] The main technical solutions of this embodiment and Embodiment 1, the features that are not explained in this embodiment, use the explanations in Embodiment 1, and will not be repeated here. In this embodiment, when the unit is applied to white cup feeding and packing, the AB unit multi-directional sliding alternate feeding transfer device is selected as the alternate feeding stacking device G, and the AB unit multi-directional sliding alternate feeding transfer device is provided with Two sets of overlapping units, the two sets of overlapping units can be divided into A unit and B unit, A unit and B unit work together alternately. Each group of stacking units includes a material receiving tray G1, a primary driving mechanism and a secondary driving mechanism. The primary driving mechanism includes a mounting plate G2-1, a primary slider G2-2, a primary guide rail G2-3, The first-level drive device G2-4 and the first-level support table G2-5, the material receiving tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com