Gun-closing unloading shutdown device of high-pressure cleaning machine

A technology of high-pressure cleaning and shutdown devices, which is applied to spraying devices, liquid spraying devices, cleaning methods and appliances, etc., which can solve problems such as damage to internal parts and affect service life, so as to improve pressure-holding performance, save energy, and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described below in conjunction with the accompanying drawings.

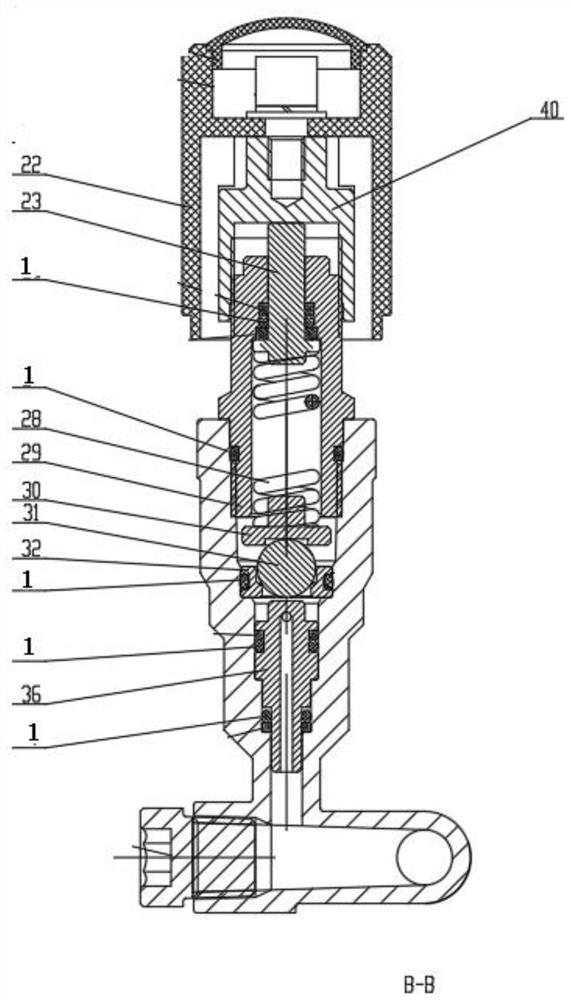

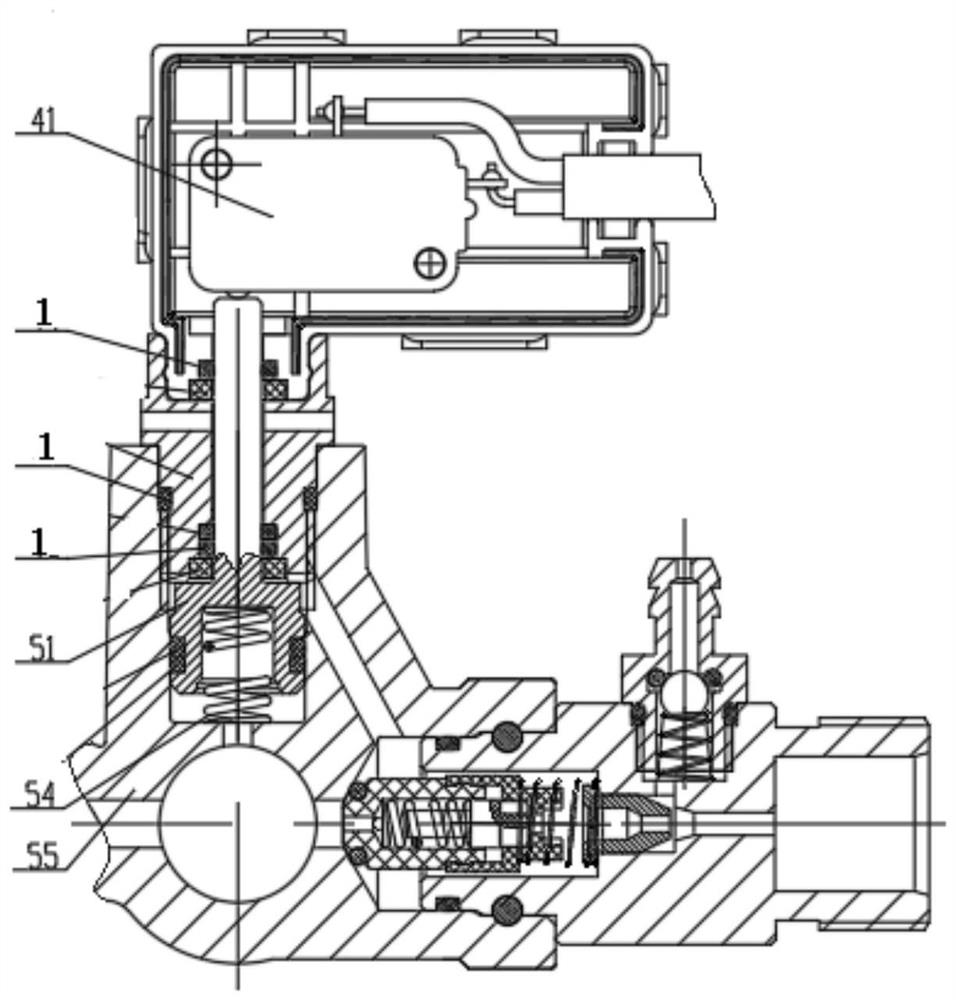

[0021] like Figure 1-3 As shown, the present invention discloses a high-pressure cleaning machine gun unloading shutdown device, including a high-pressure water outlet valve 16 provided at the water inlet and water outlet of the plunger pump. The water outlet side of the horizontal channel is provided with a pressure maintaining valve, and the longitudinal channel is provided with a pressure regulating valve and a pressure relief valve in sequence from top to bottom. The pressure relief valve includes a pressure relief ejector rod 36, an overflow seat 32 and a steel ball 31. The bottom of the pressure relief jack 36 communicates with the channel where the water inlet joint 17 is installed. The pressure relief jack 36 is provided with a through hole that communicates with the water inlet. The pressure relief jack 36 is sealed with the channel where the pressure relief valve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com