Cooling apparatus for cooling a metal material and method for the production and use thereof

A cooling device and material technology, applied in workpiece cooling device, metal rolling, metal rolling, etc., can solve problems such as disadvantage and overcooling of metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

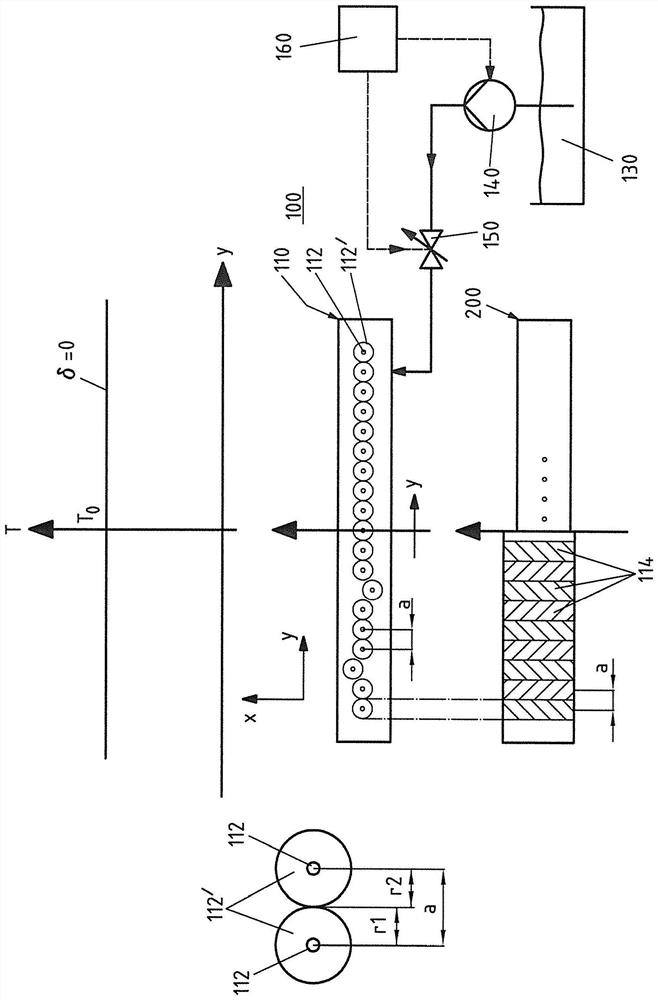

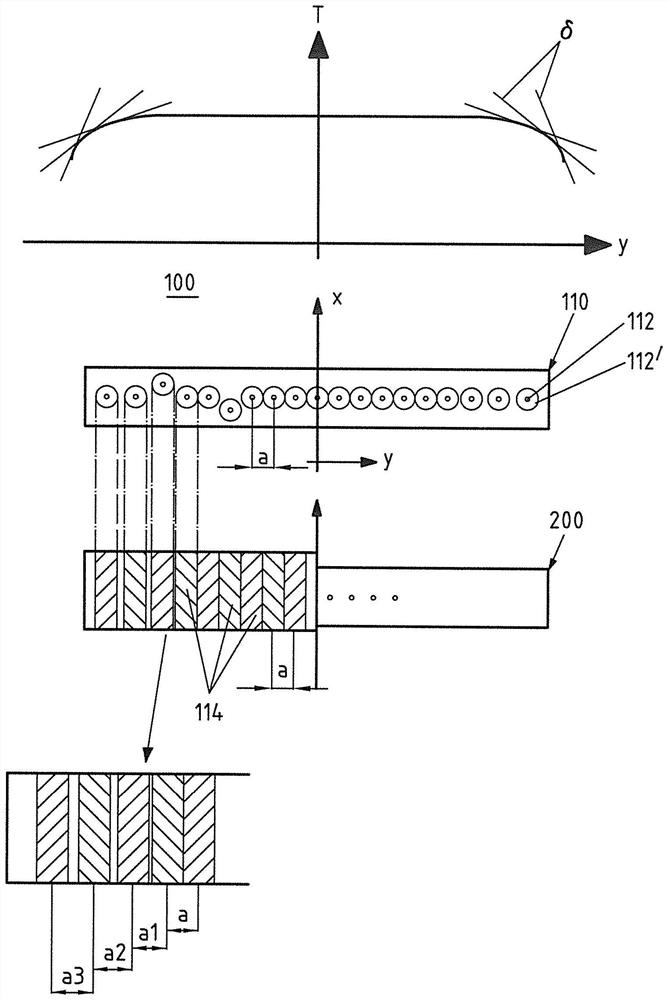

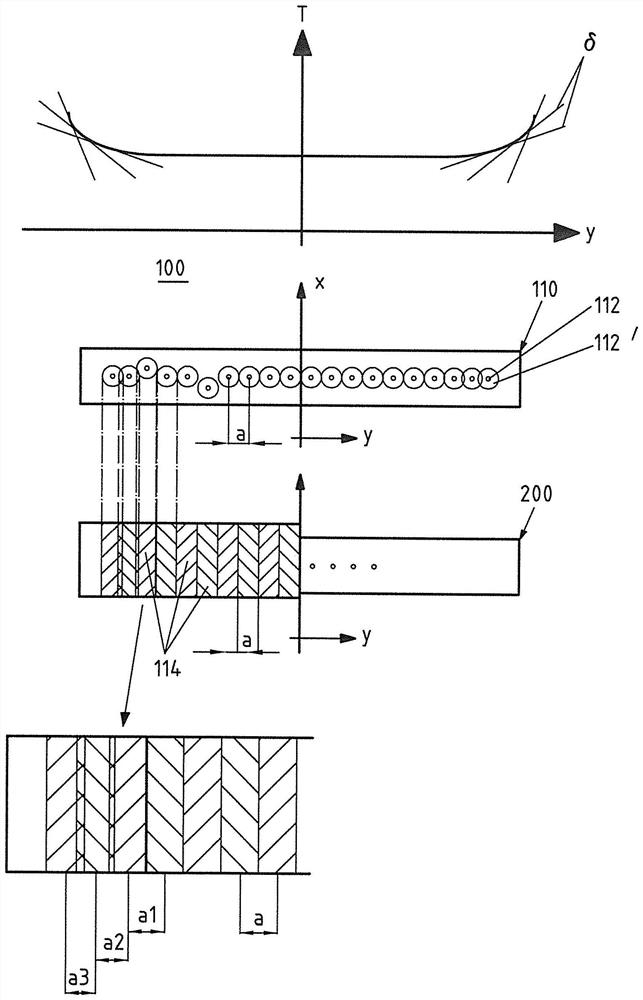

[0023] The invention is described in detail below in the form of an exemplary embodiment with the aid of the mentioned figures. In all figures, the same technical elements are provided with the same reference signs.

[0024] figure 1 In the middle is shown a cooling device 100 according to the invention for cooling a metal charge 200, as in figure 1 as shown in the lower subfigure of . The cooling device 100 includes at least one cooling beam 110 having a plurality of coolant loading elements 112 . This can be an injection nozzle, a cutout or a U-tube with a corresponding outlet opening for the coolant. exist figure 1 The dots or small circles shown in the chilled beams 110 respectively represent coolant loading elements 112 . The concentric circles around the coolant loading element 112 symbolically represent the corresponding cross section 112' of the outlet opening of the coolant loading element 112. The chilled beams 110 are loaded with coolant by means of a pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com