Method for calibrating syringe pump, syringe pump and device

A technology of syringe pumps and syringes, applied in the direction of hypodermic injection devices, medical equipment, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

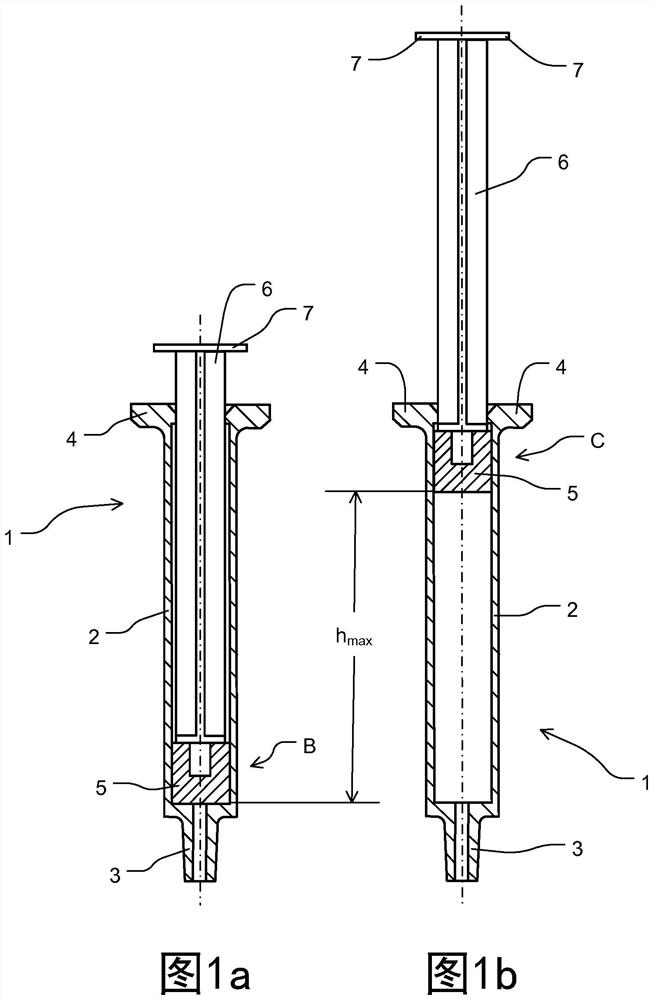

[0090] Figure 1a and Figure 1b A conventional syringe 1 , which can be a single-use syringe and / or a prefilled syringe, which can be filled with heparin, for example, is shown from the side, respectively. Figure 1a shows the syringe in its empty state, Figure 1b It is shown in its fully filled state or the state it is in when it is fully filled.

[0091] The syringe 1 comprises a syringe barrel 2 and a plunger 5 .

[0092] The syringe barrel 2 includes an optional luer cone 3 integrally formed on its head side and a syringe flange 4 formed on the opposite end.

[0093] The plunger 5 is usually made of elastomeric material and is plunger-like. A plunger 5 is located inside the syringe barrel 2 and is connected to a plunger rod 6 so that it can move axially within the syringe barrel 2 .

[0094] The end of the plunger 5 generally has an oval or circular push plate 7 when viewed from the top. exist Figure 1a and Figure 1b The push plate 7 is shown from the side.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com