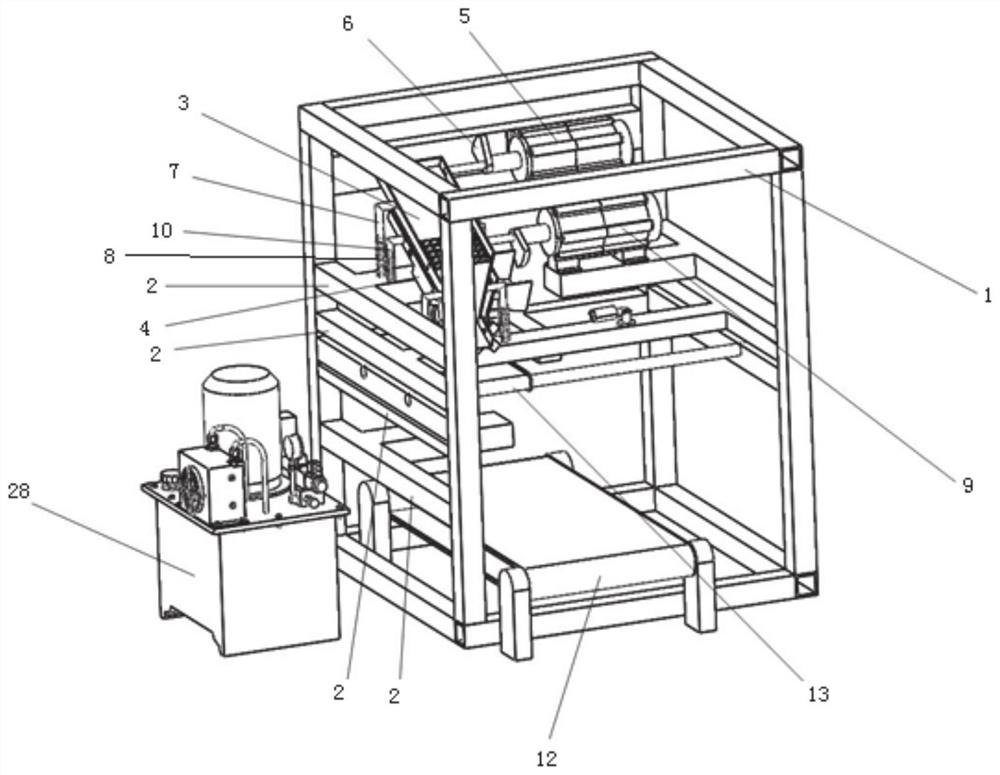

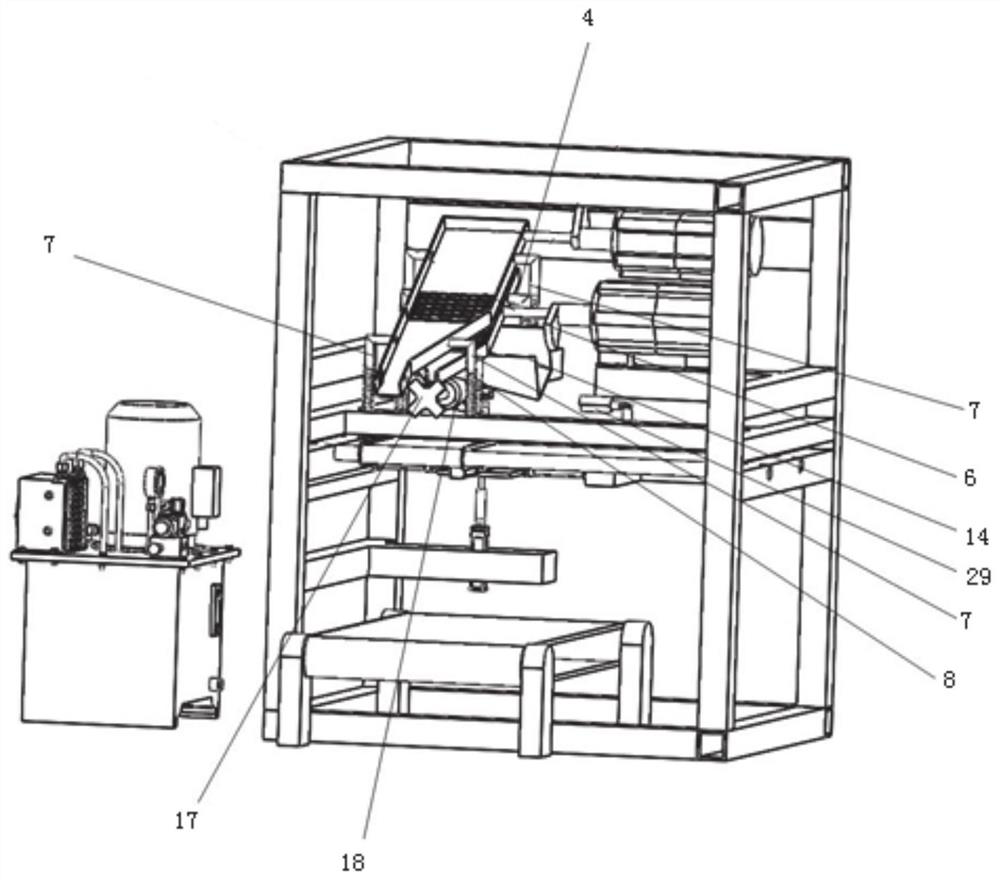

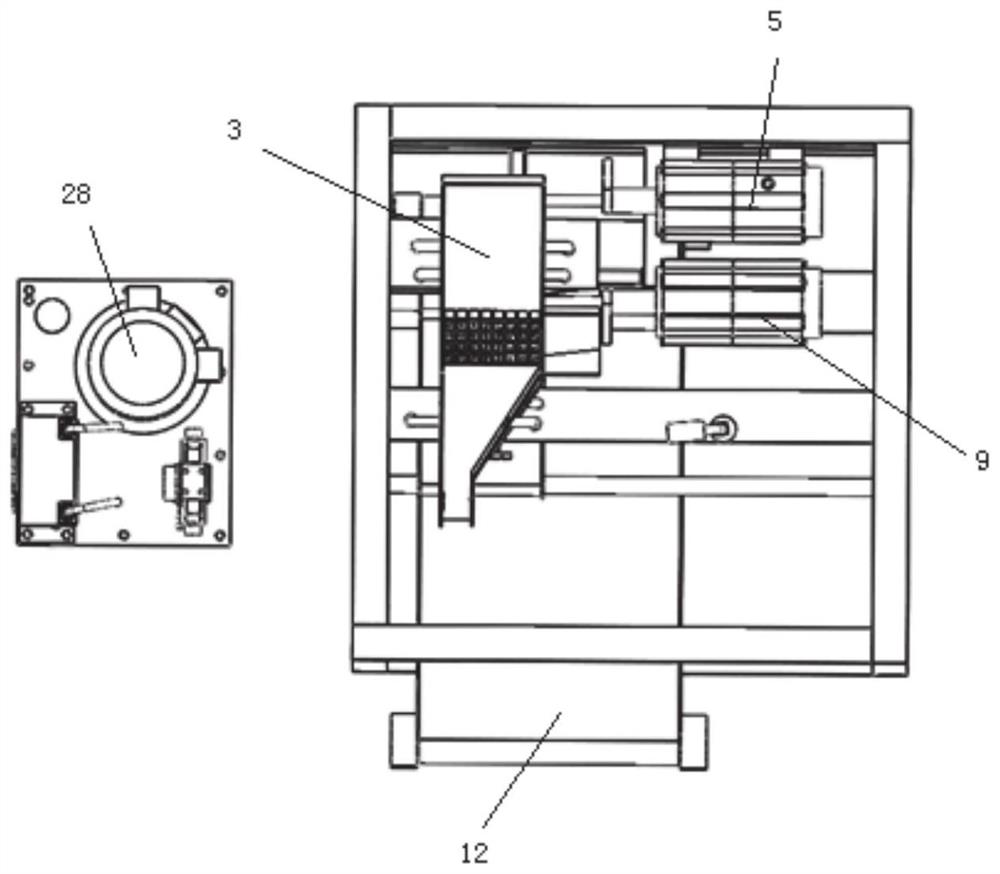

Rock-soil block point load automatic testing device and working method

An automatic testing device and point load technology, which is applied in the direction of measuring devices, testing material hardness, chemical instruments and methods, etc., can solve problems such as low efficiency, failure to meet testing requirements, and large manual testing errors, so as to improve testing efficiency, The effect of convenient collection and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0055] This embodiment discloses the working method of the automatic point load testing device for rock and soil blocks described in Embodiment 1: pour unscreened multiple rock and soil blocks into the first screen, and the first screen is placed in the first vibration mechanism. Under the action of vibration, the rock and soil blocks are screened, the rock and soil blocks falling through the first screen mesh fall into the second screen, and the rock and soil blocks that have not fallen slide down along the first screen and pass through the first discharge port Falling into the second transmission mechanism, the second screen vibrates under the action of the second vibration mechanism, and the rock and soil blocks falling through the second screen mesh fall into the material guide plate, and slide through the material guide plate to the second transmission mechanism , the rock and soil blocks that have not fallen from the second screen mesh slide down to the second discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com