Non-polar field bus system and realization method

A field bus, non-polarity technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of long preparation period, high application cost, damaged interface, etc., and achieve simple construction wiring and strong anti-interference ability , The effect of reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation steps of the field bus system proposed by the present invention will be further described below in combination with specific diagrams.

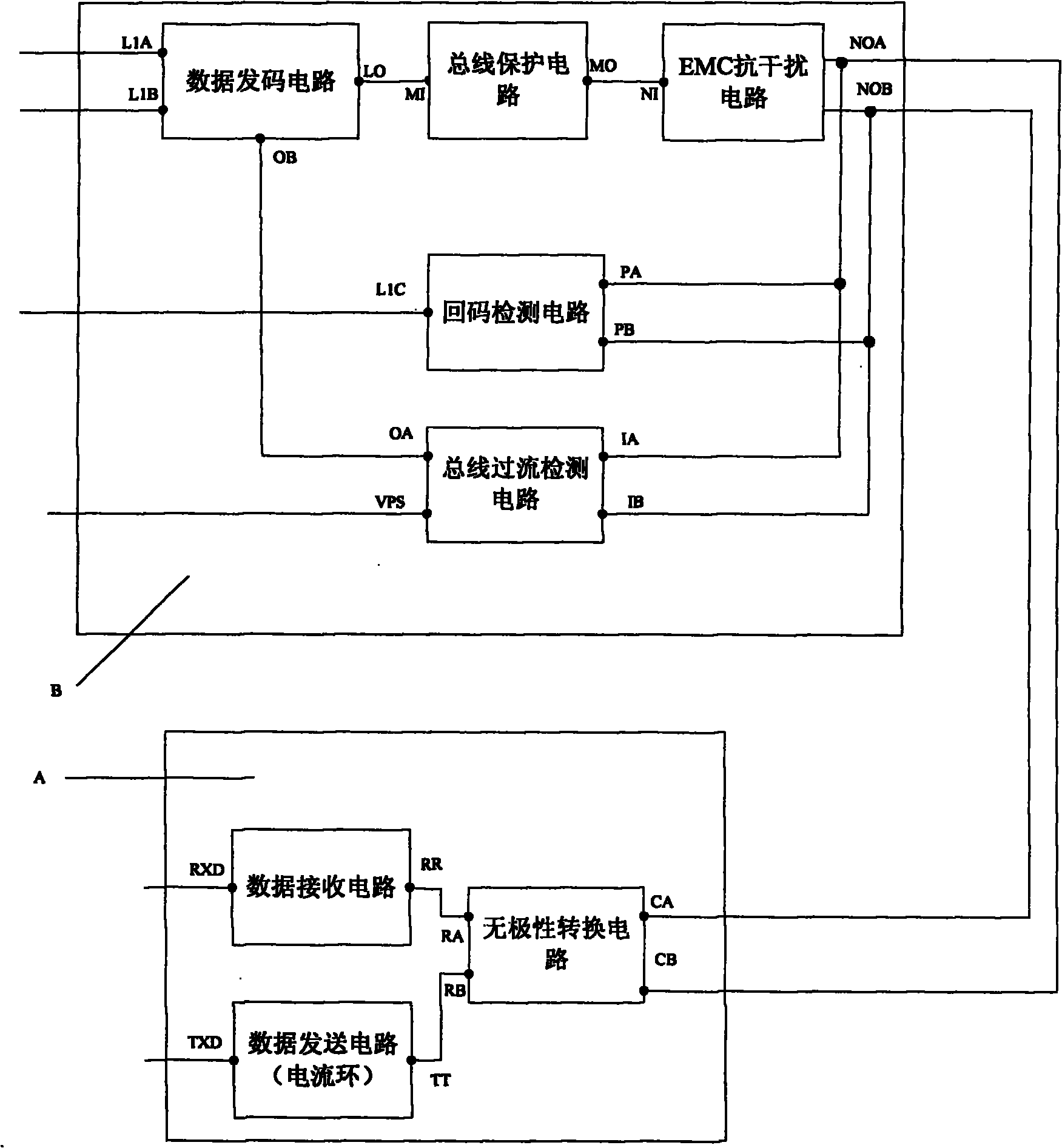

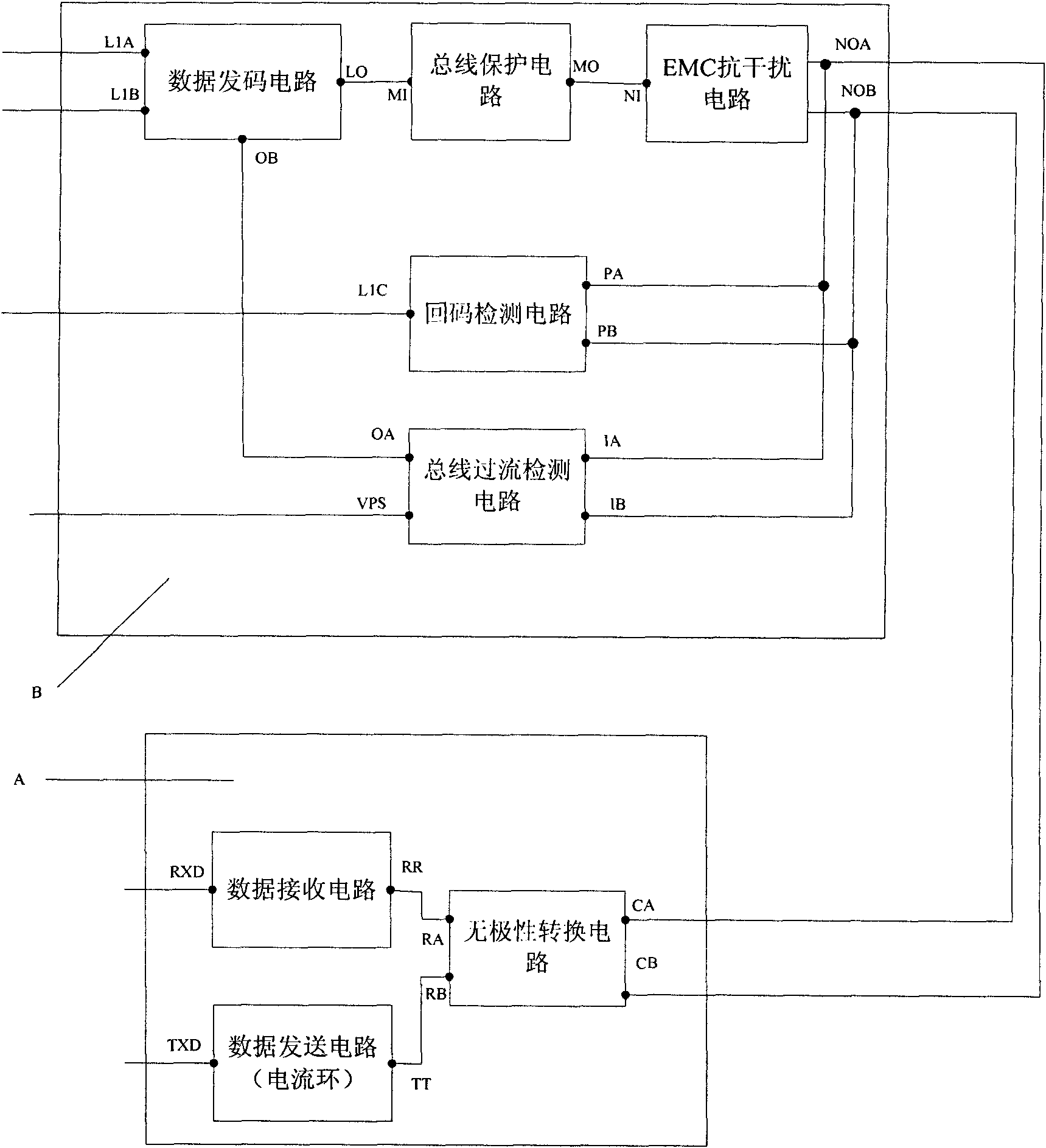

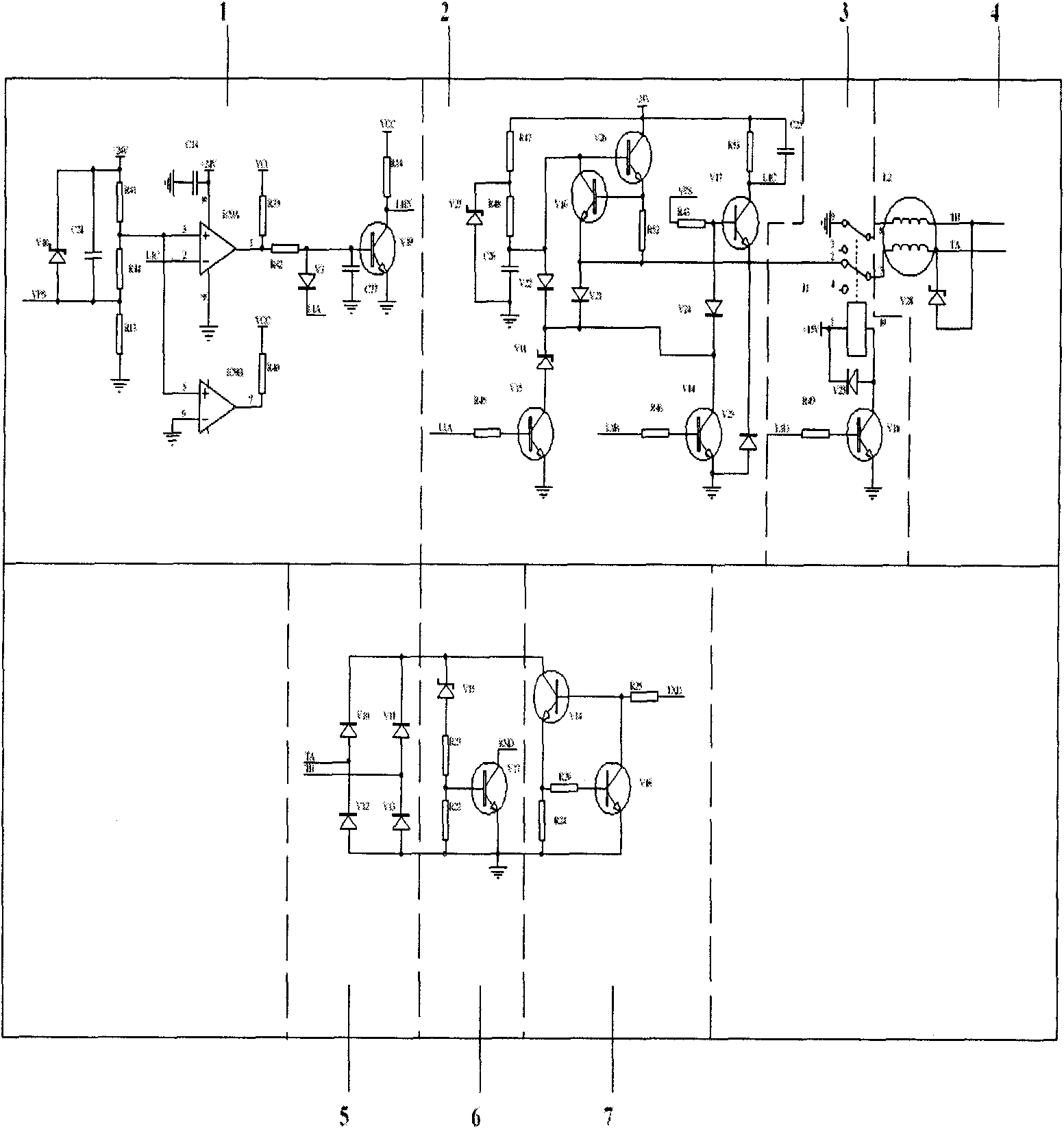

[0030]Figure 1 is a structural diagram of the non-polarity fieldbus system, including the master station DDC controller communication interface module and the slave station node controller communication interface module. The DDC controller communication interface module is composed of a data sending circuit, a bus protection circuit, an EMC anti-interference circuit, a return code detection circuit and a bus overcurrent detection circuit; the output terminal LO of the data sending circuit is connected to the input terminal of the bus protection circuit MI is connected, the output terminal MO of the bus protection circuit is connected to the input terminal NI of the EMC anti-interference circuit, the first output terminal NOA of the EMC anti-interference circuit is connected to the first non-polar cable; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com