Automobile brake disc flatness detection device

A detection device and brake disc technology, which is applied in the direction of mechanical thickness measurement, mechanical roughness/irregularity measurement, etc., can solve the problems of poor adaptability, poor precision, and high device price, and achieve low cost, strong adaptability, and detection accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

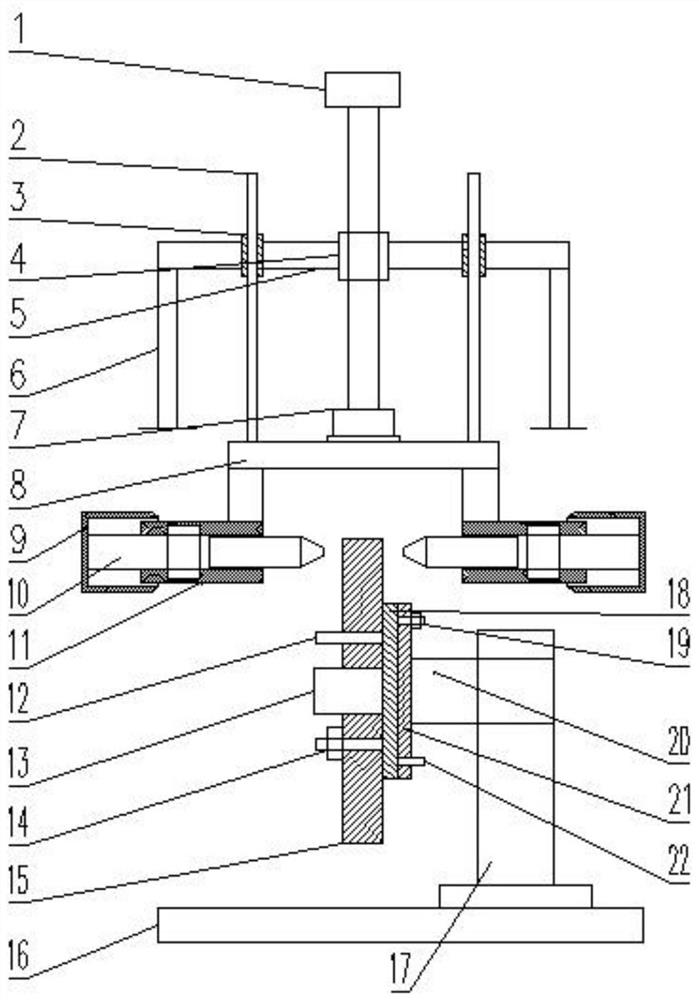

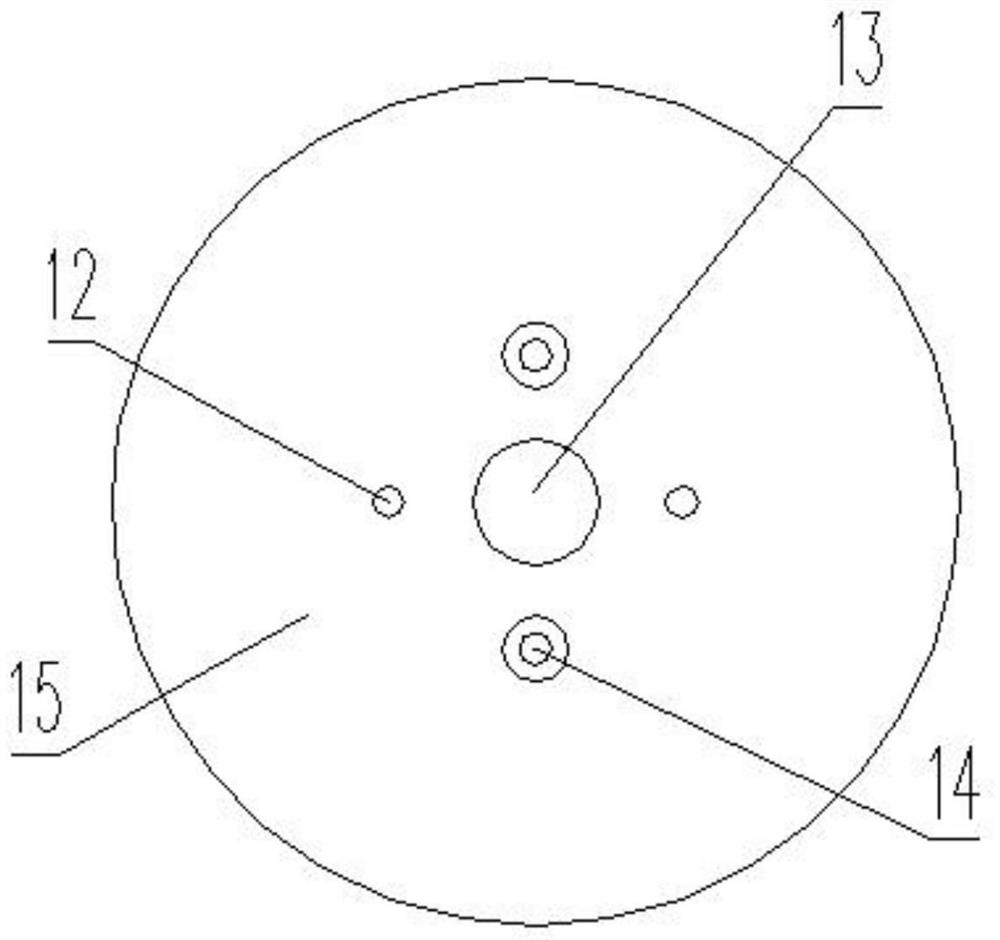

[0028] like figure 1 As shown, the automobile brake disc flatness detection device includes a measuring screw 10, a positioning disc 18, and a lifting screw 1. The quantity of the measuring screw 10 is two groups, and the two groups of measuring screws 10 are symmetrically arranged on both sides of the brake disc 15 top. The middle part of the measuring screw 10 passes through the second threaded sleeve 11, the second threaded sleeve 11 is screwed with the measuring screw 10, the front end of the measuring screw 10 is fixed with a rotating sleeve 9, and the rear part of the rotating sleeve 9 is covered in front of the second threaded sleeve 11 The outer surface of the second threaded sleeve 11 is provided with a scale, and the outer surface of the rotating sleeve 9 is provided with a scale value. Two groups of second threaded sleeves 11 are symmetrically fixed on the lower end of the fixed frame 8, and the lower end of the lifting screw 1 is inserted into the In the bearing 7,...

Embodiment 2

[0031] like Figure 1-4As shown, the automobile brake disc flatness detection device includes a measuring screw 10, a positioning disc 18, and a lifting screw 1. The quantity of the measuring screw 10 is two groups, and the two groups of measuring screws 10 are symmetrically arranged on both sides of the brake disc 15 top. The middle part of the measuring screw 10 passes through the second threaded sleeve 11, the second threaded sleeve 11 is screwed with the measuring screw 10, the front end of the measuring screw 10 is fixed with a rotating sleeve 9, and the rear part of the rotating sleeve 9 is covered in front of the second threaded sleeve 11 The outer surface of the second threaded sleeve 11 is provided with a scale, and the outer surface of the rotating sleeve 9 is provided with a scale value. Two groups of second threaded sleeves 11 are symmetrically fixed on the lower end of the fixed frame 8, and the lower end of the lifting screw 1 is inserted into the In the bearing ...

Embodiment 3

[0034] like Figure 1-5 As shown, the automobile brake disc flatness detection device includes a measuring screw 10, a positioning disc 18, and a lifting screw 1. The quantity of the measuring screw 10 is two groups, and the two groups of measuring screws 10 are symmetrically arranged on both sides of the brake disc 15 top. The middle part of the measuring screw 10 passes through the second threaded sleeve 11, the second threaded sleeve 11 is screwed with the measuring screw 10, the front end of the measuring screw 10 is fixed with a rotating sleeve 9, and the rear part of the rotating sleeve 9 is covered in front of the second threaded sleeve 11 The outer surface of the second threaded sleeve 11 is provided with a scale, and the outer surface of the rotating sleeve 9 is provided with a scale value. Two groups of second threaded sleeves 11 are symmetrically fixed on the lower end of the fixed frame 8, and the lower end of the lifting screw 1 is inserted into the In the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com