Device and method for monitoring oil stealing and leakage of optical cable in oil pipeline

A monitoring device and oil pipeline technology, applied in measuring devices, pipeline systems, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as difficult to find problems, difficult to timely and accurately find, easy to miss detection period and other problems, and achieve reasonable and good design. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0339] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

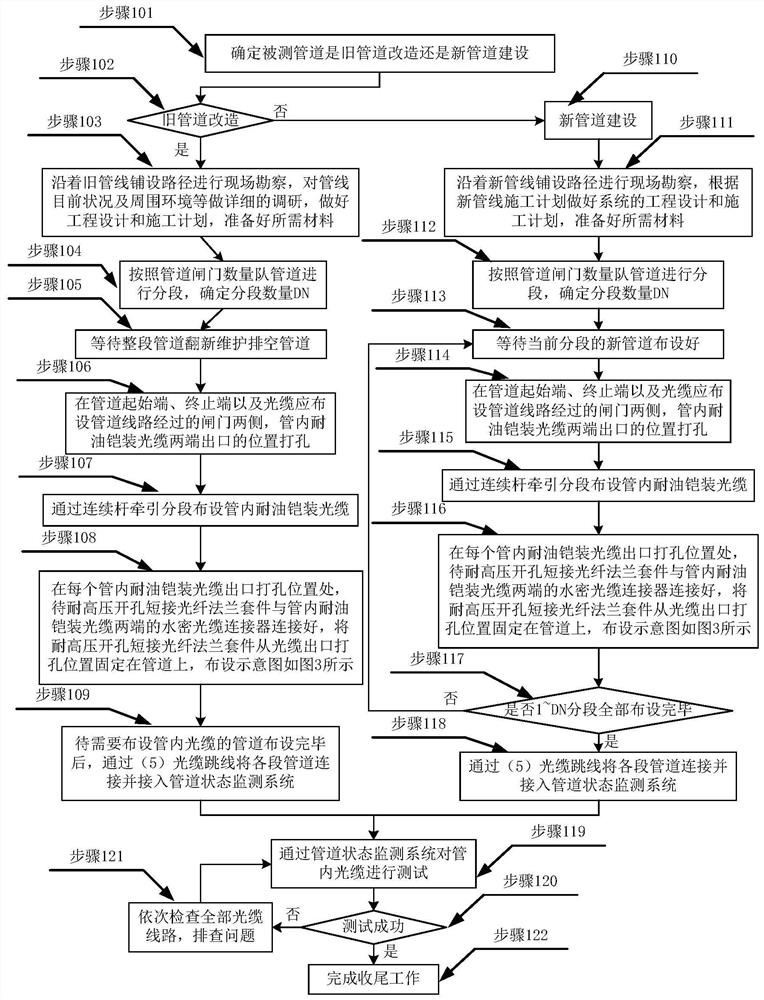

[0340] The present invention is an optical cable oil stealing and leakage monitoring device in an oil pipeline, and the overall scheme is composed as follows figure 1 As shown in , through the main server to control the pipeline status monitoring system at both ends, the optical cables laid in the pipeline are alternately and continuously tested to avoid the failure of the pipeline to cause the optical cable to cause a whole section of the pipeline to be unable to monitor.

[0341] A device for monitoring oil theft and leakage of optical cables in oil pipelines, including a master server 1, a first pipeline status monitoring system 2, a second pipeline status monitoring system 3, a watertight optical cable connector 4, an optical cable jumper 5, and a high-voltage resistant opening Short-circuit fiber optic flange kit 6 and oil-resistant armored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com