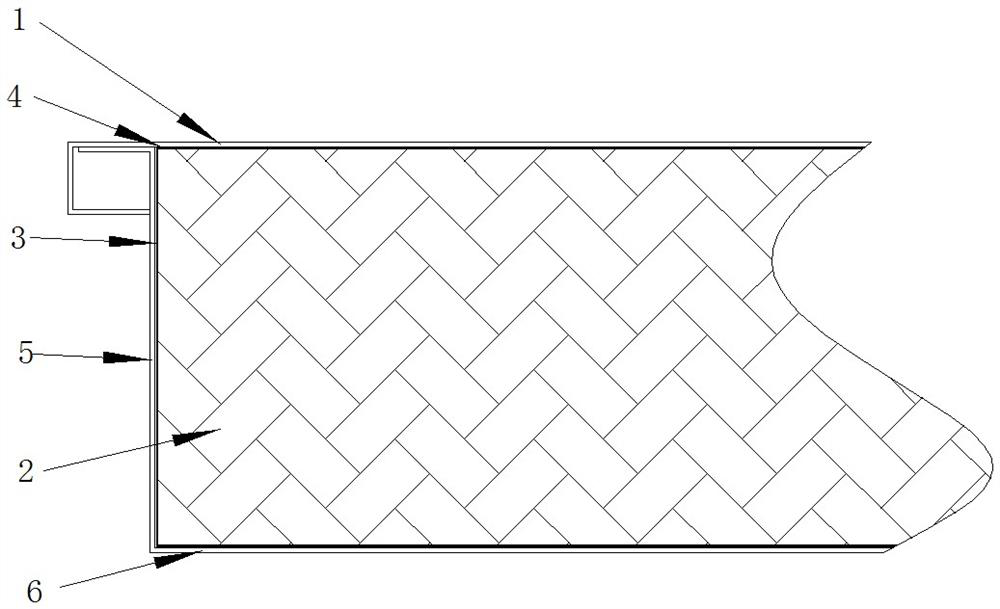

Fireproof door with sealing layer for preventing peculiar smell from overflowing and manufacturing method thereof

A manufacturing method and technology of a sealing layer, applied in fire doors, door leaves, windows/doors, etc., can solve the problems of fire door odor spillage, product quality damage to users, and fire doors with no odor spill seal layer yet. The effect of resolving discomfort and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

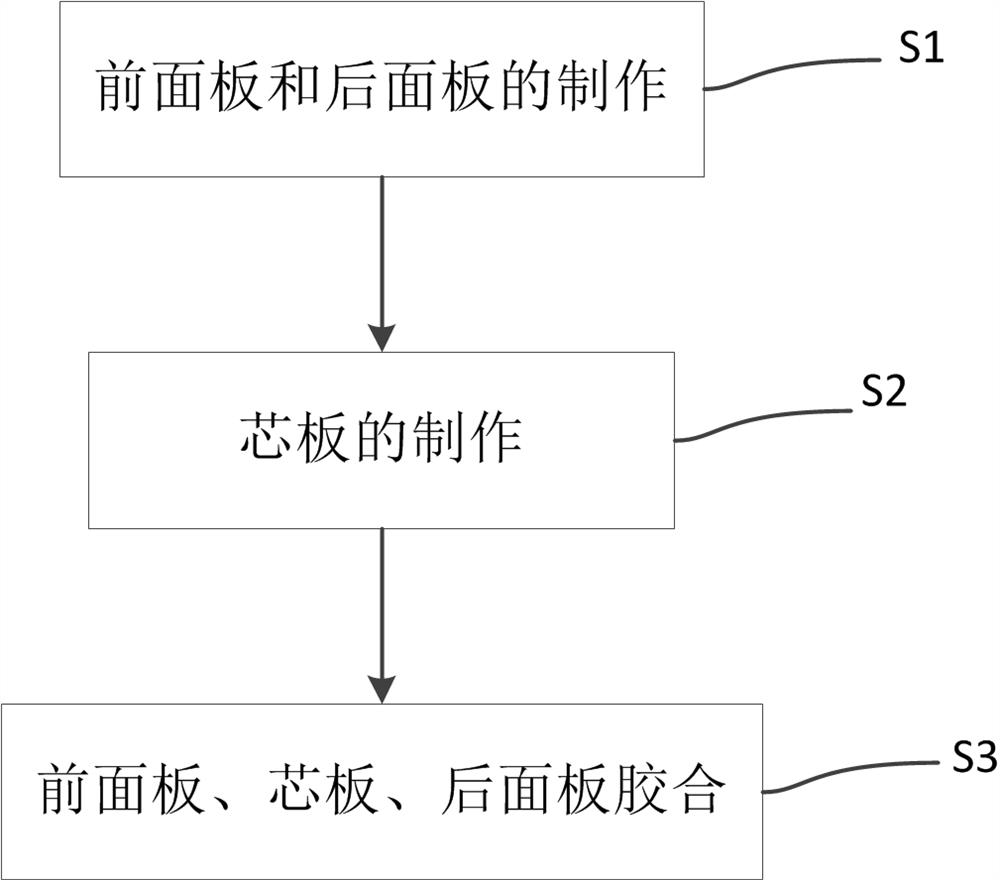

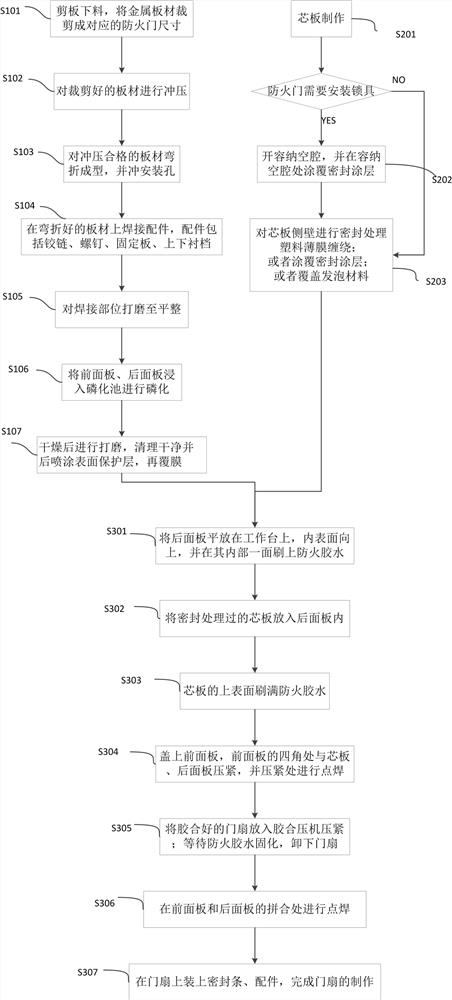

Method used

Image

Examples

Embodiment 2

[0089] The same as the first embodiment will not be repeated, the difference is: the side wall 5 of the core board 2 is coated with a sealing layer 3 formed by a sealing coating. The sealing coating can effectively cover the surface of the core board 2 and improve the reliability of the sealing; the sealing coating can be formed by brushing fireproof glue, spraying waterproof materials, and the like.

Embodiment 3

[0091] The same as Embodiment 1 will not be repeated, the difference is that: the side wall 5 of the core board 2 covers the sealing layer 3 formed by foaming glue, and the foaming glue can fully cover the core board 2, and can also pass through the foaming equipment. Cover the core with styrofoam.

[0092] above Figure 1-Figure 3 The shown fire door with the anti-odor sealing layer and its manufacturing method is a specific embodiment of the present invention, which has already reflected the substantive features and progress of the present invention, and can be used according to actual needs under the inspiration of the present invention. , equivalent modification of its shape, structure, etc., are all within the scope of protection of this scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com