Flood control steel gate for water conservancy treatment and implementation method thereof

A gate and water conservancy technology, applied in the field of water conservancy project management, can solve problems such as high limitations, reduced gate service life, steel gate damage, etc., and achieve the effect of high installation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

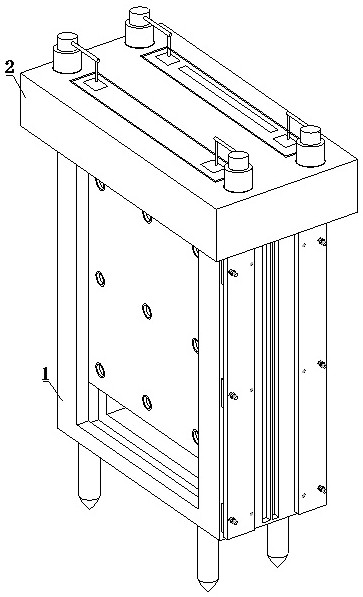

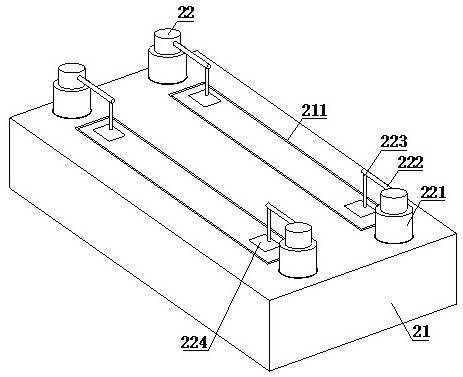

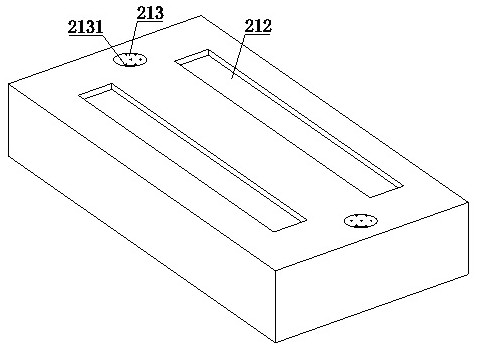

[0035] refer to figure 1 , 2 , 4, 5 and 6, a steel gate for water conservancy control for flood control, including a main casing 1 and an end body mechanism 2, the upper end of the main casing 1 is provided with an end body mechanism 2, and the main casing 1 includes a full concave sliding Groove 11, semi-recessed chute 12, first gate 13, second gate 14, side chute 15, connector 16, spare gate 17, connecting pile 18, top port 19 and pre-embedded steel pipe 1A, main shell 1 The inner wall is provided with a full concave chute 11 and a half concave chute 12, the inside of the full concave chute 11 is provided with a first gate 13, the inside of the half concave chute 12 is provided with a second gate 14, and the outside of the main housing 1 Both sides of the surface are provided with side slide grooves 15, the connecting piece 16 is fixedly installed on both sides of the main casing 1, the spare gate 17 is arranged on the outer surface of the main casing 1, and the connecting ...

Embodiment approach , 1 Embodiment approach

[0039] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a steel gate for water conservancy treatment of flood prevention, comprising the following steps:

[0040] Step 1: When the river channel is matched: embed the embedded steel pipe 1A on the lower bottom surface of the main shell 1 into the bottom of the river channel so that the whole is fixed without shaking, and at the same time connect the spare gate 17 to the outer surface of the main shell 1 through the locking bolt 162 Face-to-face connection;

[0041] Step 2: When the river channel is wide: the overall width of the main housing 1 is difficult to reach the width of the river channel, the spare gate 17 is connected to the main housing 1 through the side chute 15, and the outer surfaces of the two extrusion blocks 172 are The magnetic joint 1721 on the contact, form a fixed;

[0042] Step 3: When it is necessary to rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com