Galling device for paving cement road

A napping device and cement road technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of different shades, rough napping is not smooth enough, etc., achieve high napping quality, standard napping spacing, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

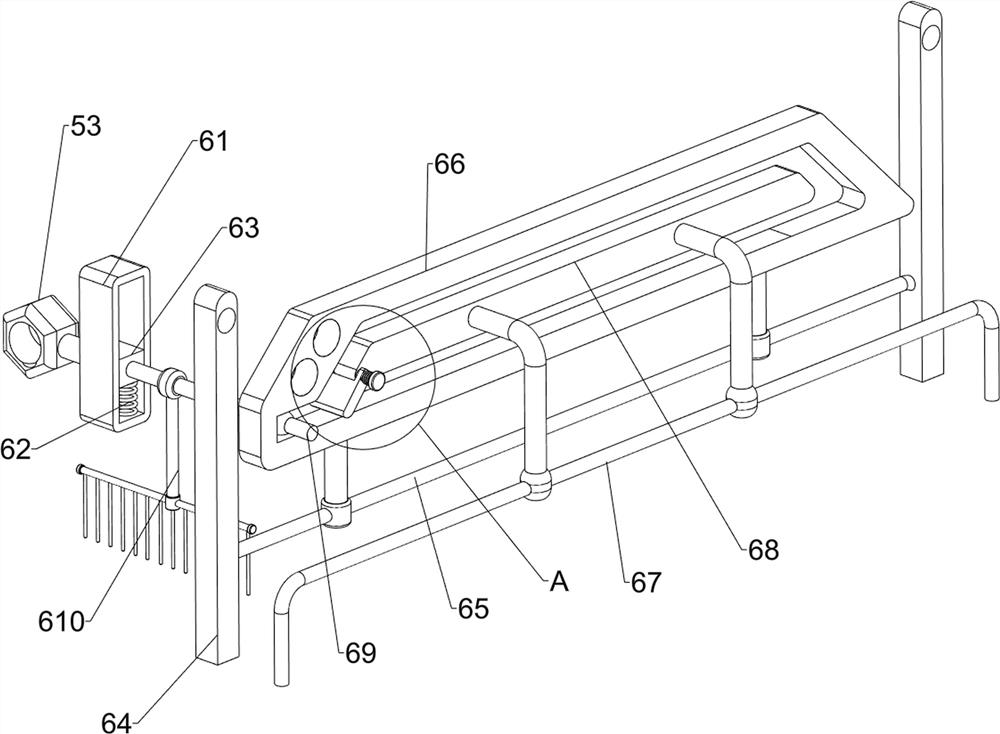

[0055] A kind of napping device for bedding cement road, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a wheel 1, a mounting plate 2, a first bracket 3, a mounting seat 4, a moving mechanism 5 and a scraping mechanism 6, and the front and rear sides of the mounting plate 2 are symmetrically arranged with wheels 1, and the front side of the top of the mounting plate 2 The left and right parts are symmetrically provided with a first bracket 3, the upper part of the right side of the first bracket 3 is provided with a mounting seat 4, the upper front side of the mounting plate 2 is provided with a moving mechanism 5, and the upper rear side of the mounting plate 2 is provided with a scraping mechanism 6.

[0056] When people need to roughen the cement road surface, first push the device to the road surface that needs roughening, then start the moving mechanism 5, the movement of the moving mechanism 5 drives the movement of the scrapi...

Embodiment 2

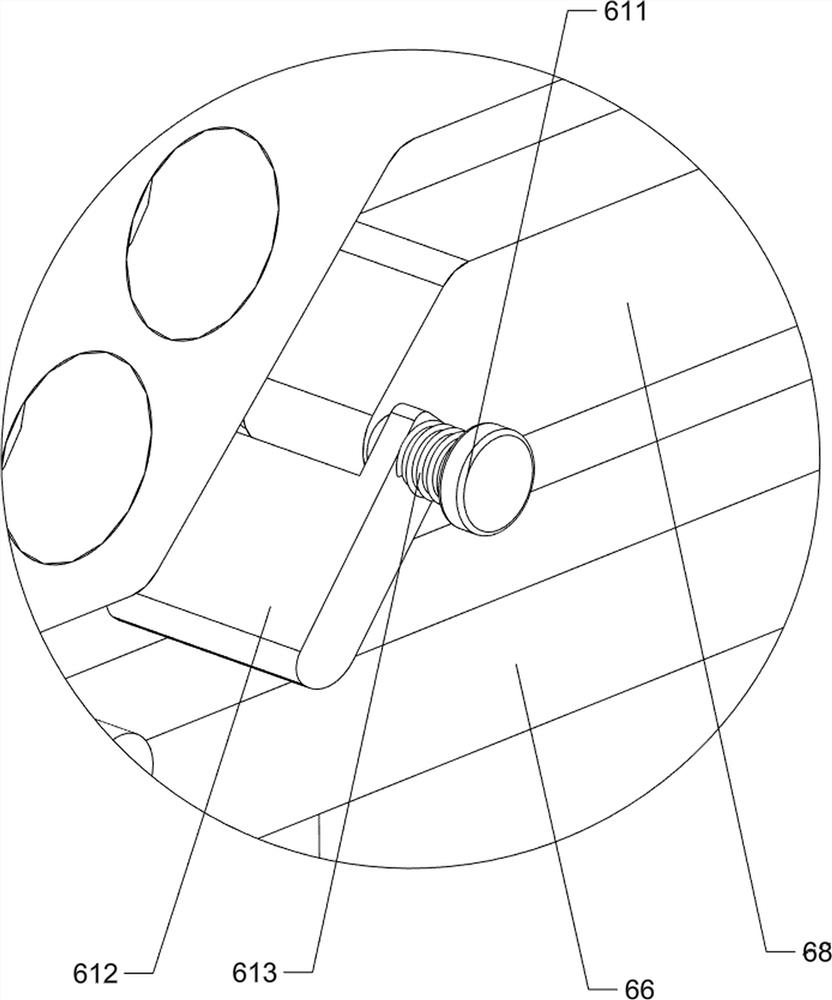

[0062] On the basis of Example 1, such as Figure 5 As shown, a walking mechanism 7 is also included, and the walking mechanism 7 includes a rack 71, a bearing seat 72, a second rotating shaft 73, a spur gear 74, a first transmission assembly 75, a third rotating shaft 76, a bevel gear set 77, a second L rod 78 and the second transmission assembly 79, the rear end of the moving rod 69 is provided with a rack 71, the middle of the top of the first wedge block 66 is provided with a bearing seat 72, and the inner rotation of the bearing seat 72 is provided with a second rotating shaft 73, the second rotating shaft 73 rear ends are provided with spur gear 74, and spur gear 74 cooperates with rack 71, and second support 64 upper side rotation type is provided with the 3rd rotating shaft 76, all connects between the 3rd rotating shaft 76 of left and right sides and the 2nd rotating shaft 73 There is a first transmission assembly 75, a second L bar 78 is provided on the upper right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com