Alkaline cleaning agent for hollow fiber ultrafiltration membrane as well as preparation method and application thereof

A technology of ultrafiltration membrane and cleaning agent, which is applied in the preparation of detergent mixture composition, surface active detergent composition, ultrafiltration, etc., and can solve the problems of low membrane flux recovery rate, rapid membrane flux decline rate, and Flux recovery rate is small and other problems, to achieve good cleaning effect, high membrane flux recovery rate, increase the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

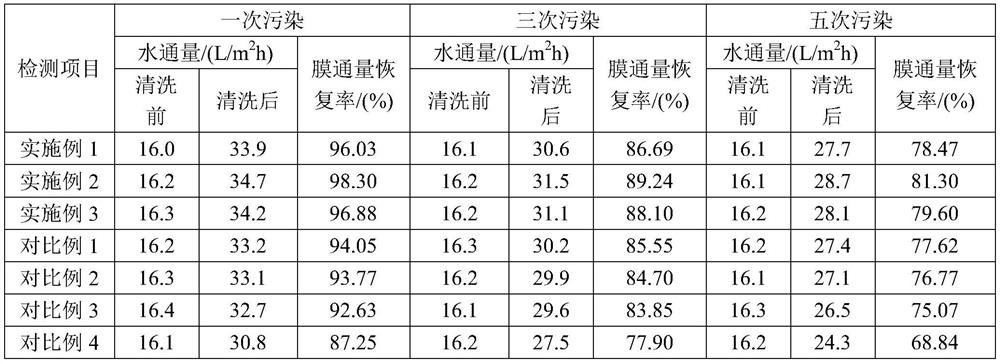

Examples

Embodiment 1

[0045] An alkaline cleaning agent for a hollow fiber ultrafiltration membrane, the raw material ratio of which is shown in Table 1.

[0046] Wherein, the pH adjusting agent includes sodium hydroxide, sodium carbonate, and sodium bicarbonate, and the weight ratio of sodium hydroxide, sodium carbonate, and sodium bicarbonate is 10:3:1; the membrane protecting agent is glycerol.

[0047] A preparation method for an alkaline cleaning agent for a hollow fiber ultrafiltration membrane, comprising the steps of:

[0048] S1. Heat the water to 70°C, then add non-ionic penetrant, glycerol block polyether, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate, sodium lauryl sulfate, mix well, get mixture a;

[0049] S2, adding a chelating dispersant, a film protecting agent, and a plant polyphenol into the mixture a to obtain the mixture b;

[0050] S3. Add a pH adjuster to the mixture b, mix evenly, and cool down to obtain an alkaline cleaning agent. ...

Embodiment 2

[0052] An alkaline cleaning agent for a hollow fiber ultrafiltration membrane, the raw material ratio of which is shown in Table 1.

[0053] Wherein, the pH adjusting agent includes sodium hydroxide, sodium carbonate, and sodium bicarbonate, and the weight ratio of sodium hydroxide, sodium carbonate, and sodium bicarbonate is 10:3.5:1.5; the membrane protecting agent is pentaerythritol.

[0054] A preparation method for an alkaline cleaning agent for a hollow fiber ultrafiltration membrane, comprising the steps of:

[0055] S1. Heat the water to 60°C, then add non-ionic penetrant, glycerol block polyether, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate, sodium lauryl sulfate, mix well, get mixture a;

[0056] S2, adding a chelating dispersant, a film protecting agent, and a plant polyphenol into the mixture a to obtain the mixture b;

[0057] S3. Add a pH adjuster to the mixture b, mix evenly, and cool down to obtain an alkaline clean...

Embodiment 3

[0059] An alkaline cleaning agent for a hollow fiber ultrafiltration membrane, the raw material ratio of which is shown in Table 1.

[0060] Wherein, the pH adjusting agent includes sodium hydroxide, sodium carbonate, and sodium bicarbonate, and the weight ratio of sodium hydroxide, sodium carbonate, and sodium bicarbonate is 10:4:2; the membrane protecting agent is diethylene glycol.

[0061] A preparation method for an alkaline cleaning agent for a hollow fiber ultrafiltration membrane, comprising the steps of:

[0062] S1. Heat the water to 50°C, then add non-ionic penetrant, glycerol block polyether, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate, sodium lauryl sulfate, mix well, get mixture a;

[0063] S2, adding a chelating dispersant, a film protecting agent, and a plant polyphenol into the mixture a to obtain the mixture b;

[0064] S3. Add a pH adjuster to the mixture b, mix evenly, and cool down to obtain an alkaline cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com