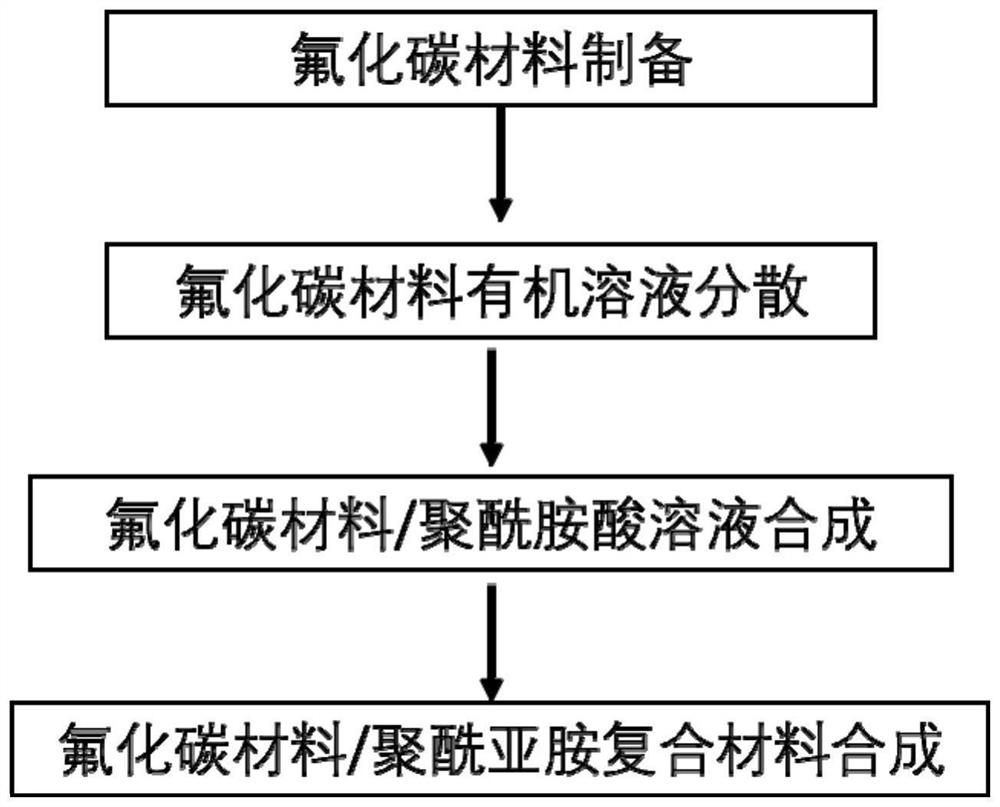

Polyimide composite material and preparation method and application thereof

A technology of composite materials and polyimide, which is applied in the direction of circuits, electrical solid state devices, semiconductor devices, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1: fluorinated graphene / polyimide composite material

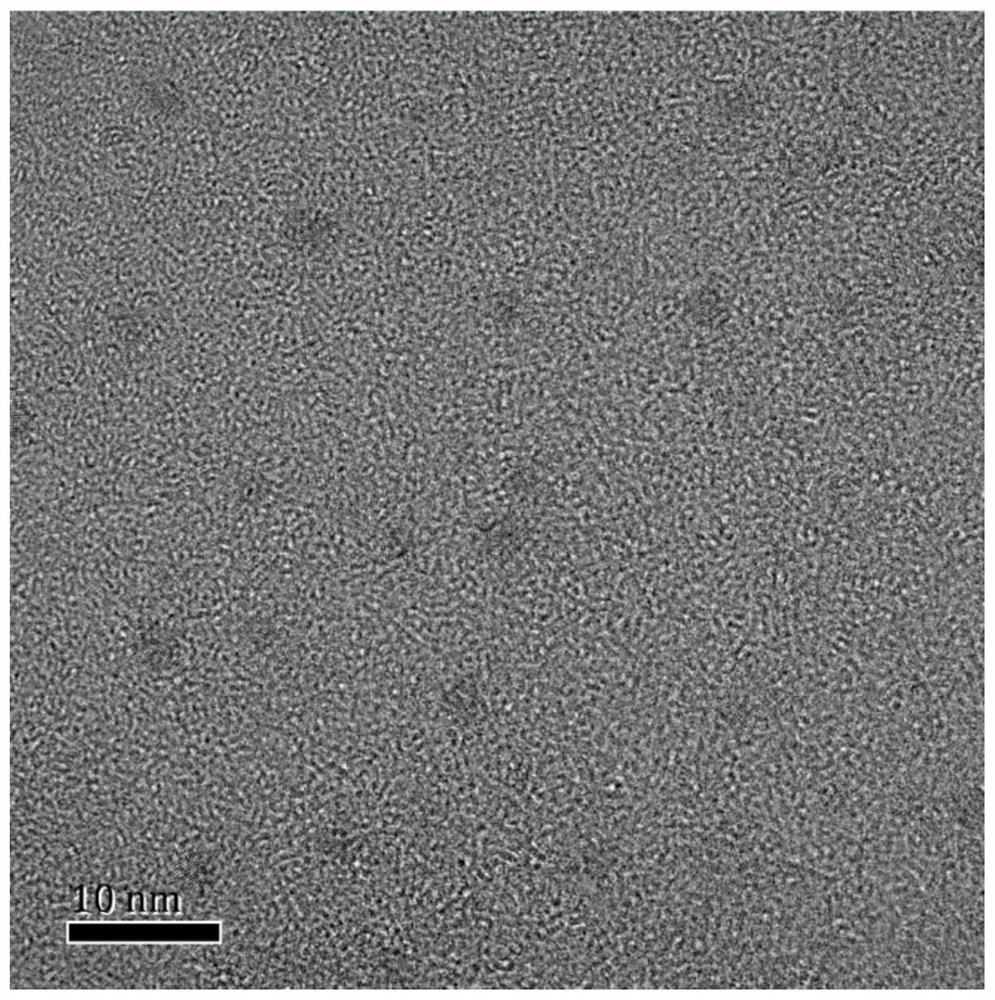

[0091] (1) Preparation of graphene oxide

[0092] First, add 4 g of graphite and 120 mL of concentrated H to a glass bottle in an ice bath at 0 °C 2 SO 4 , then add 2 g of NaNO under constant stirring3 and 20 g of KMnO 4 And react for 1h. Then, it was kept in a 35°C water bath for 1 hour. Finally, deionized water was added up to 500 mL at 45 °C, followed by H 2 o 2 (30%) treatment, the solid matter (graphene oxide) obtained by centrifugation (9500 rpm) was washed successively with 5% hydrochloric acid and deionized water until the pH was adjusted to 7.

[0093] The above-mentioned graphene oxide is frozen by liquid nitrogen, and then thoroughly dried in a freeze dryer to obtain graphene oxide airgel powder.

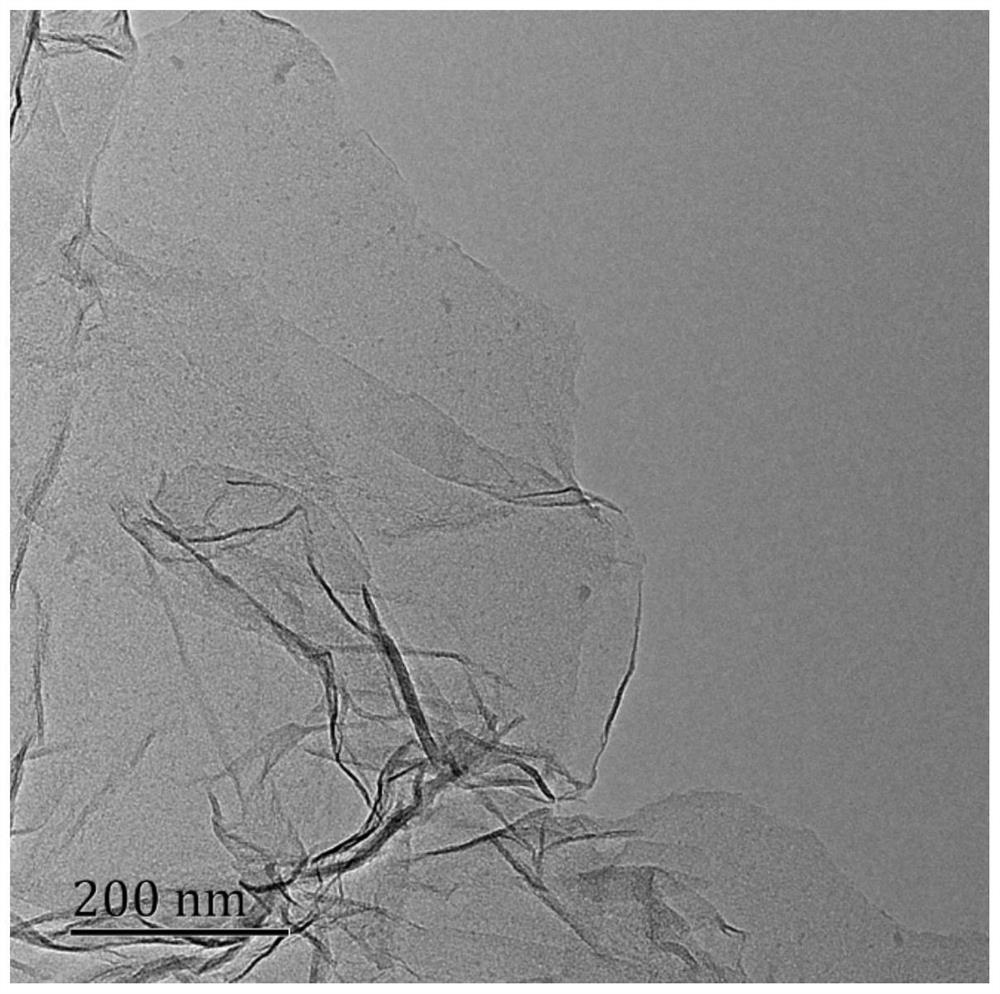

[0094] (2) Preparation of fluorinated graphene

[0095] Take 1g of the above-mentioned graphene oxide airgel powder and add it to a reaction kettle of 500mL tetrafluoroethylene, add 5g XeF 2...

Embodiment 2

[0100] The only difference from Example 1 is that in step (3), the added amount of fluorinated graphene is 0.01 g, and the content of fluorinated graphene in the obtained composite material is 0.25%.

Embodiment 3

[0102] The only difference from Example 1 is that in step (3), the added amount of fluorinated graphene is 0.04g, and the content of fluorinated graphene in the obtained composite material is 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com