Heavy deviation rectifying device

A deviation-correcting device, heavy-duty technology, applied in the direction of cleaning device, transportation and packaging, conveyor objects, etc., can solve the problems of complicated operation mode and poor effect, and achieve the effect of convenient operation, compact structure and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

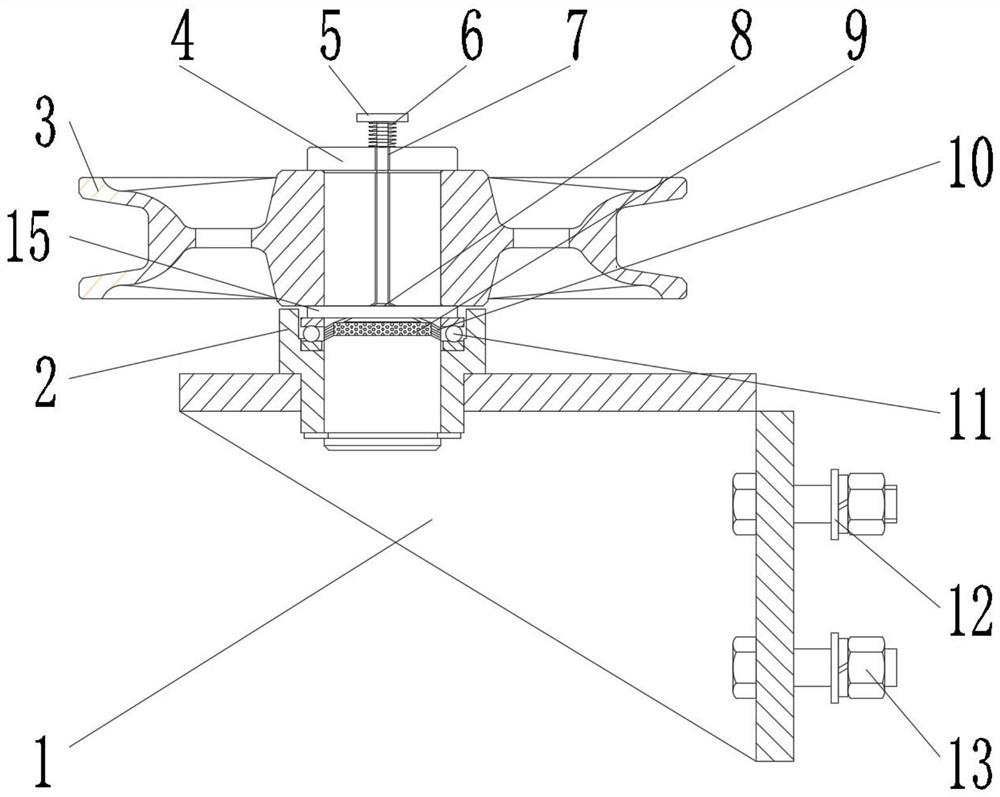

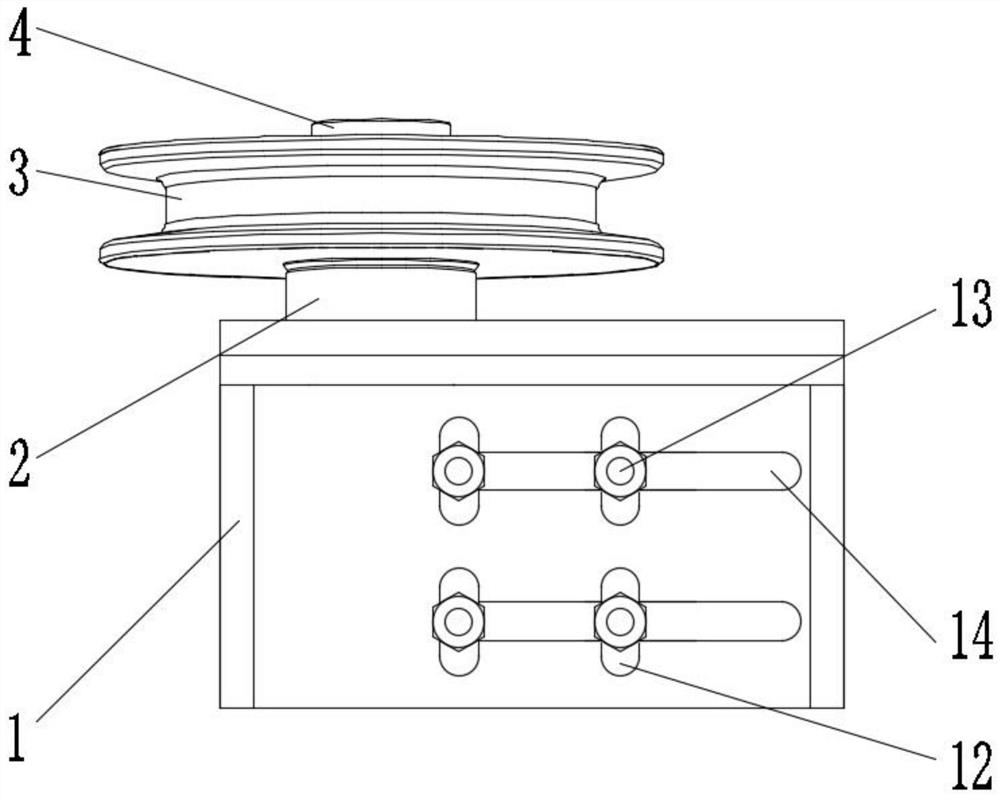

[0023] Such as Figure 1-2 As shown, the embodiment of the present invention provides a heavy-duty deviation correction device, which includes a mounting bracket 1, a bearing mounting seat 2 is fixedly installed on the top of the mounting bracket 1, a plane bearing 11 is fixedly installed inside the bearing mounting seat 2, and the bearing mounting seat 2 A connecting shaft 4 is installed inside, the connecting shaft 4 runs through the plane bearing 11, one end of the connecting shaft 4 extends to the inside of the bearing mount 2, the other end of the connecting shaft 4 extends above the bearing mount 2, and the outer surface of the connecting shaft 4 The sheave set 3 is sheathed, the bottom of the sheave set 3 is fixedly connected with a connecting cylinder 15, the connecting cylinder 15 is fixedly sleeved on the outer surface of the connecting shaft 4, the bottom of the connecting cylinder 15 fits the top of the plane bearing 11, There is an oil storage tank 7 inside the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com