Double-station automatic labeling method

A double-station, labeling technology, applied in labeling machines, labels, packaging, etc., can solve problems such as high cost, low work efficiency, and inability to adjust adaptively, and achieve low cost, small installation space, and improved labeling The effect of standard processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

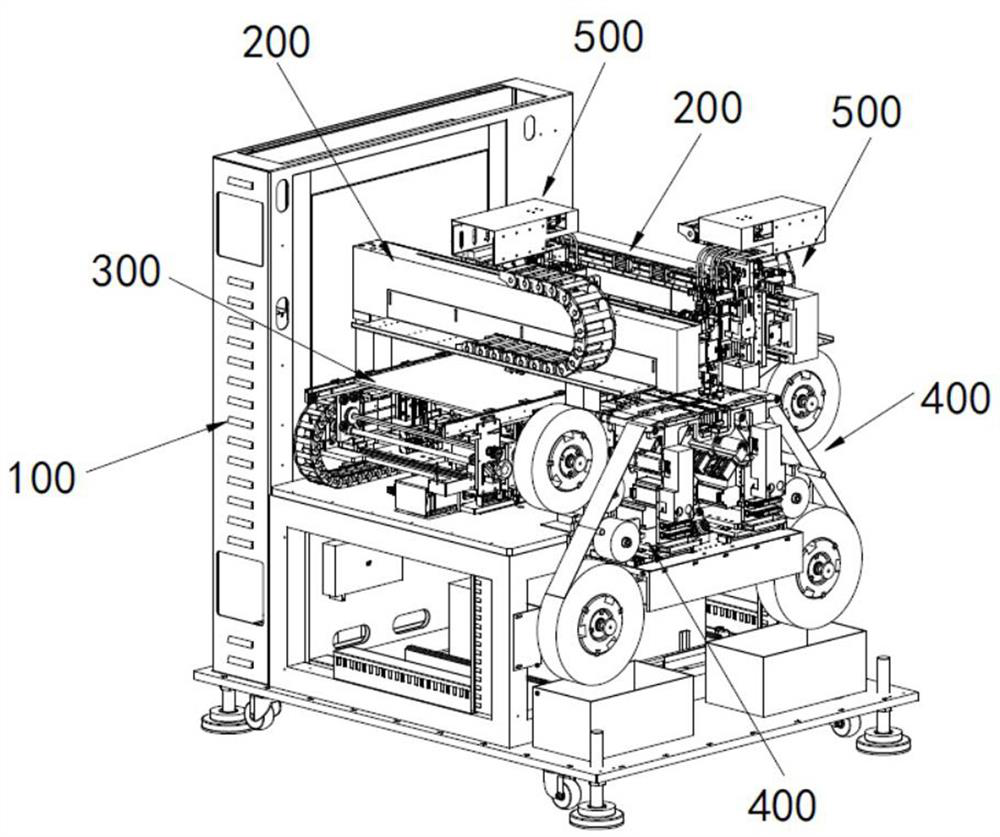

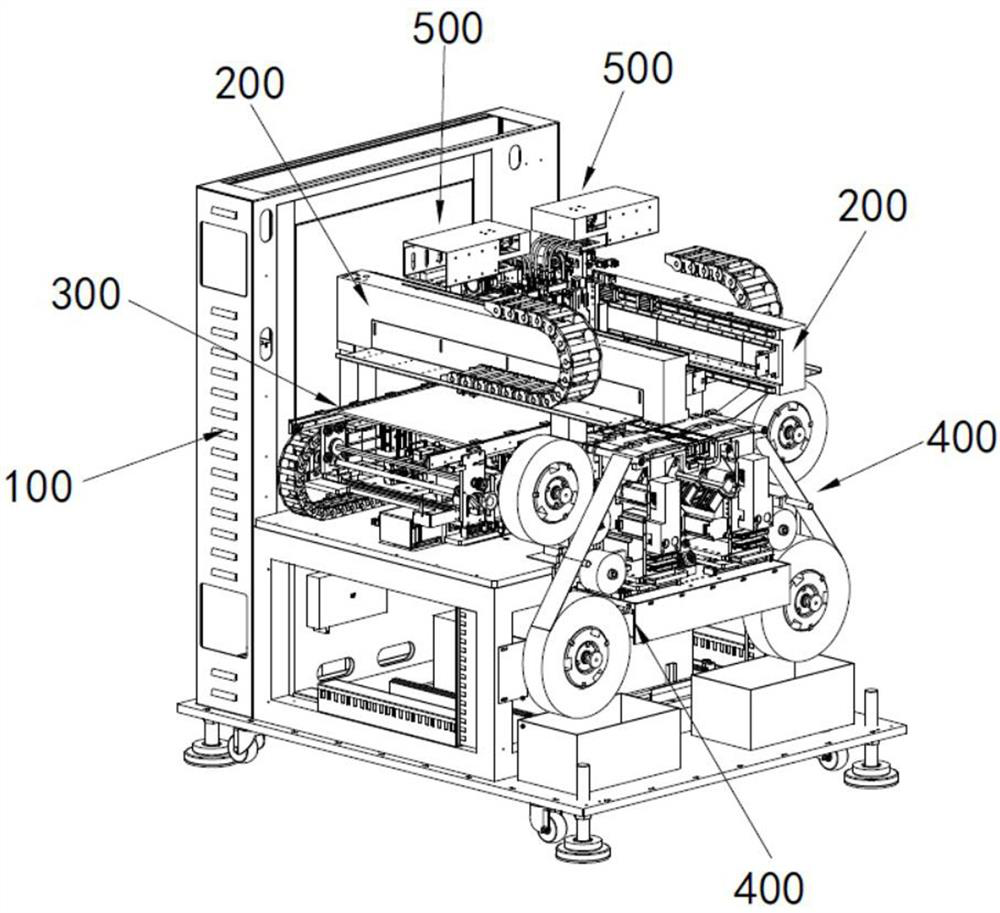

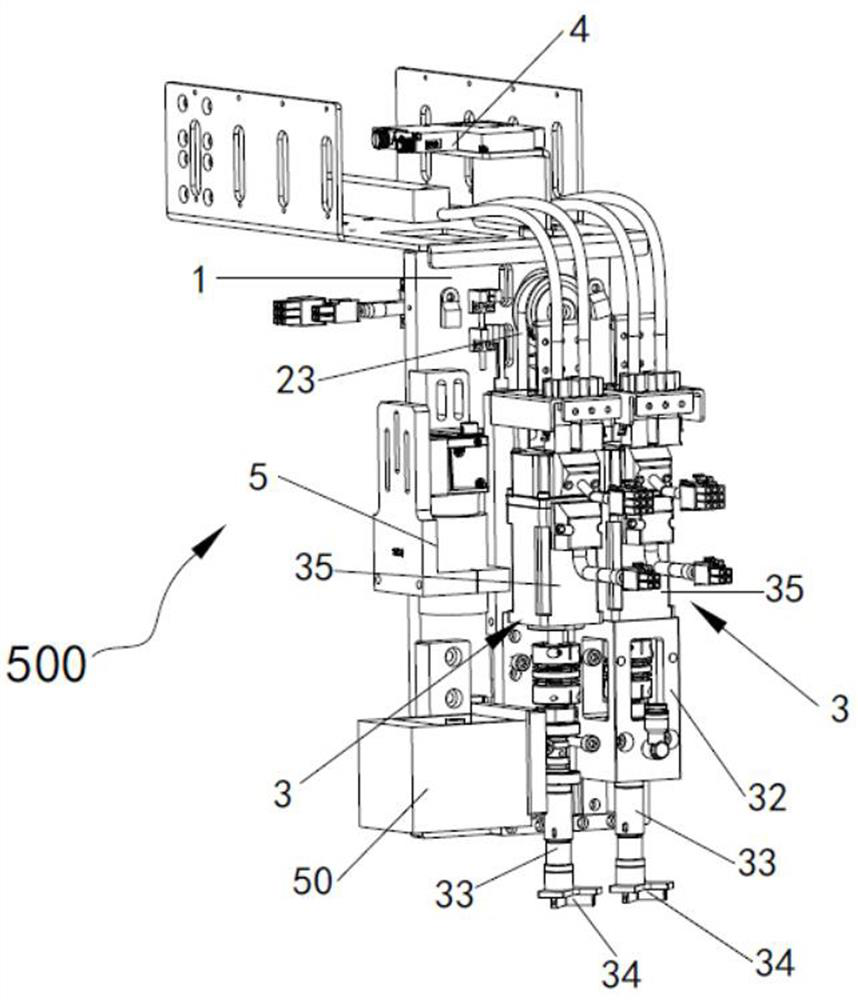

[0023] see figure 1 , figure 2 Shown is a multi-station automatic labeling equipment used in the present invention, which includes a machine 100, a workpiece transfer module 300 for transferring workpieces to be labeled, a feeding module 400 for supplying labels, and The labeling module 500 is used to absorb labels and perform labeling operations on workpieces to be labeled, wherein the workpieces to be labeled are transported along the first direction, and the first direction is also the delivery direction; After the label is picked up on the feeding station of group 400, it moves to the top of the workpiece to be labeled in the workpiece transfer module 300, and performs labeling operations on the workpiece to be labeled. The labeling module 500 starts from the top of the feeding station The movement path moving above the workpiece to be labeled is the labeling movement path, and its movement direction is the second direction, and the second direction is perpendicular to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com