Connecting tube for stethoscope and ear hook rubber tube connecting assembly

A technology for connecting components and connecting tubes, which is applied in stethoscopes and other directions, and can solve problems such as the narrowing of lumen sound guide channels, increasing user costs, and the inability of doctors to auscultate with fine audio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

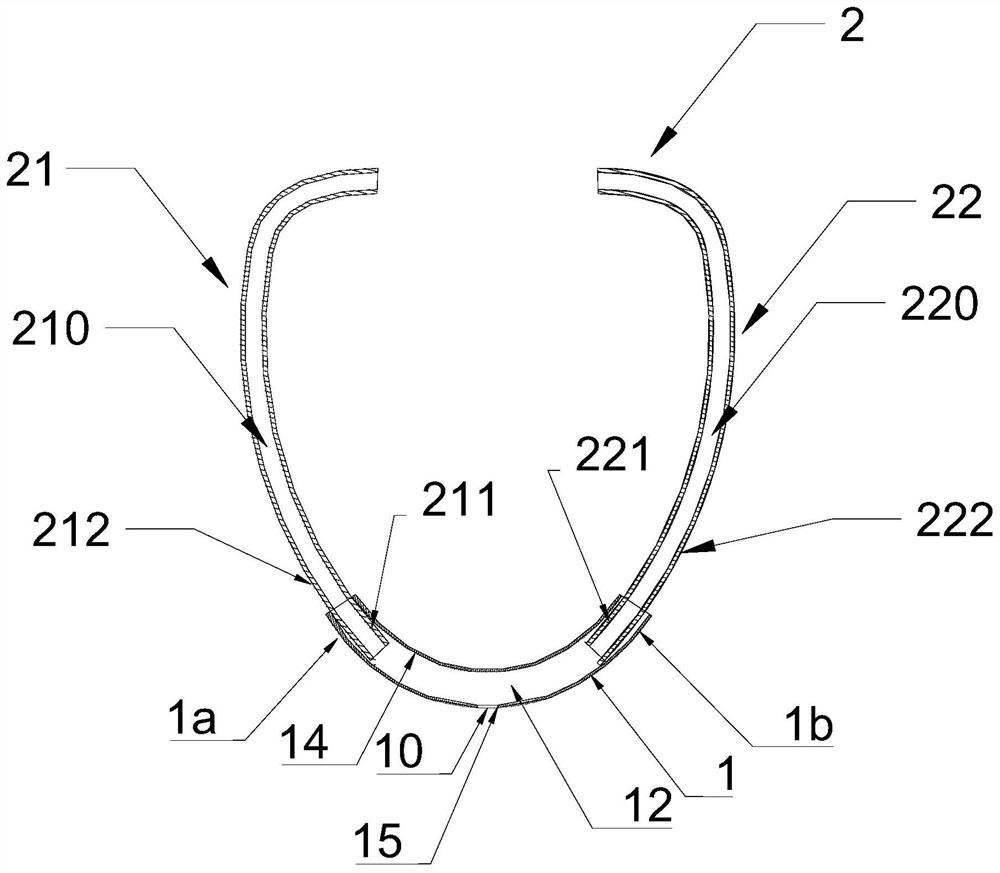

[0075] Embodiment 1: in combination with figure 1 , figure 2 , image 3 , Figure 8 Shown, the present invention is described further.

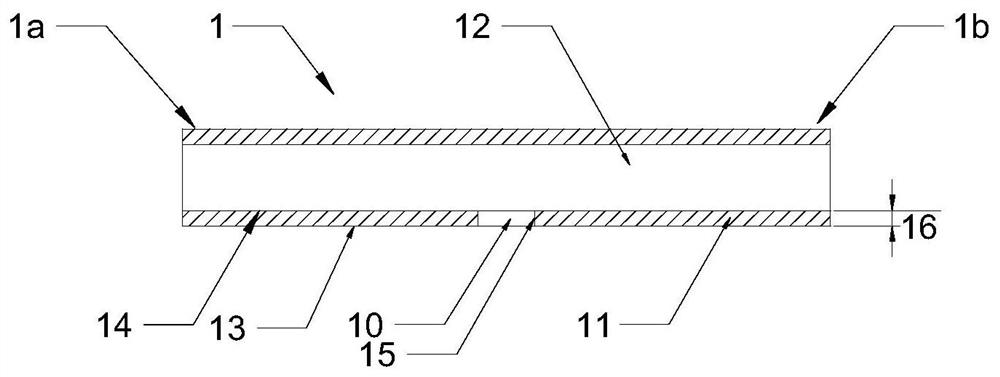

[0076] The stethoscope uses a connecting tube 1, which is a flexible, straight hollow rubber tube. The connecting pipe 1 is provided with a terminal 1a and a terminal B 1b at both ends. The middle part of the connecting pipe 1 is provided with a hole 10 passing through the pipe wall 11 on one side.

[0077] The earhook 2 includes a left earhook 21 and a right earhook 22 .

[0078] The connecting pipe 1 is used for connecting the earhook 2 and the sound guiding rubber tube 3 .

[0079] The A end 1a of the connecting pipe 1 is sleeved on the left earhook outer wall 212 of the left earhook rubber hose end 211 of the left earhook 21 , and the B end 1b of the connecting pipe 1 is sleeved on the right earhook rubber hose end 221 of the right earhook 22 on the outer wall 222 of the right ear. The lumen 210 of the left earhook communicates ...

Embodiment 2

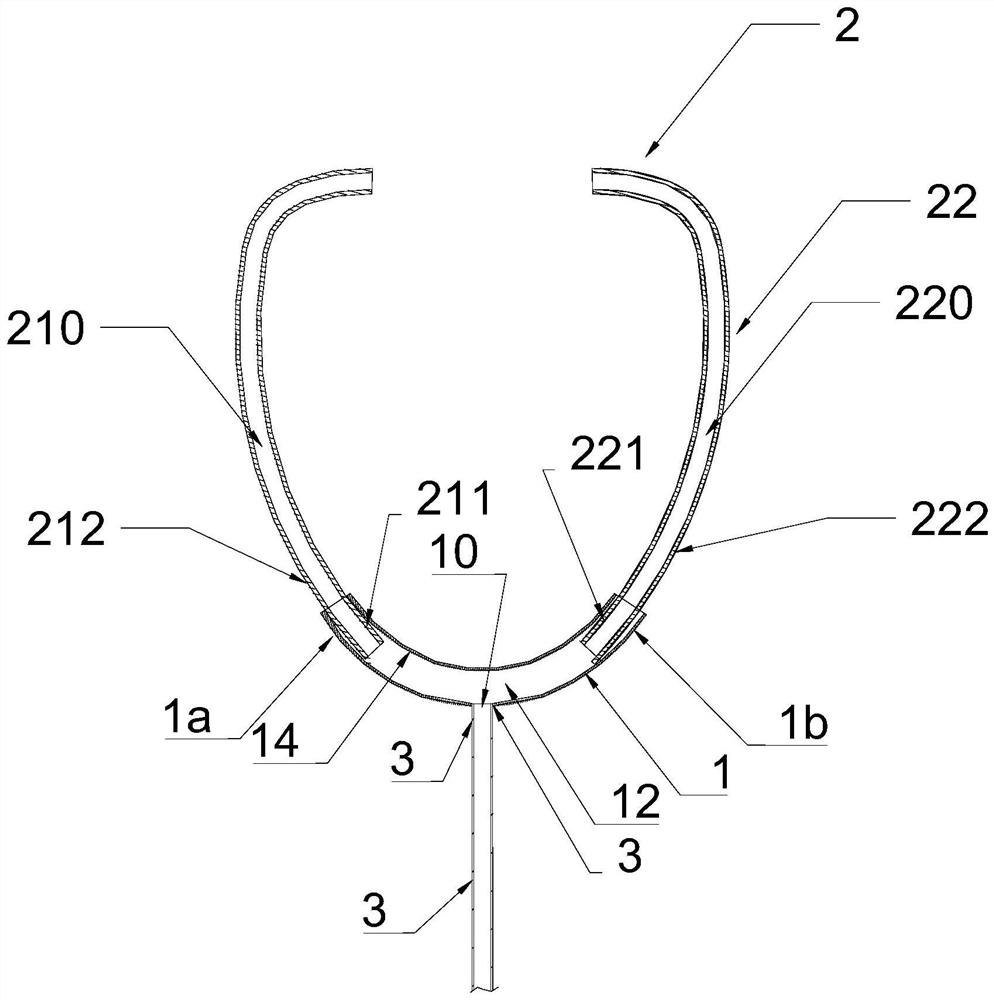

[0082] combined with figure 1 , Figure 5 , Figure 6 , Figure 8 , Figure 10 , Figure 11 Shown, the present invention is described further.

[0083] The earhook hose connection assembly for the stethoscope includes earhook 2, connecting tube 1, earhook shrapnel 5, connector 6 and sound guide hose 3.

[0084] The earhook 2 includes a left earhook 21 and a right earhook 22 .

[0085]The earhook shrapnel 5 is fixed on the earhook 2 , the A end 5a of the earhook shrapnel 5 is fixed on the outer wall 212 of the left earhook, and the B end 5b is fixed on the outer wall 222 of the left earhook.

[0086] The connecting pipe 1 is a flexible, straight hollow rubber hose. The connecting pipe 1 is provided with a terminal 1a and a terminal B 1b at both ends. The middle part of the connecting pipe 1 is provided with a hole 10 passing through the pipe wall 11 on one side.

[0087] The earhook shrapnel 5 is penetrated in the lumen 12 of the connecting tube 1. No matter how the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com