Tilia miqueliana drilling equipment for agricultural production

The technology of drilling equipment and linden is applied in the field of linden drilling equipment for agricultural production, which can solve the problems of people's fatigue and increase labor intensity, and achieve the effect of reducing manual operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

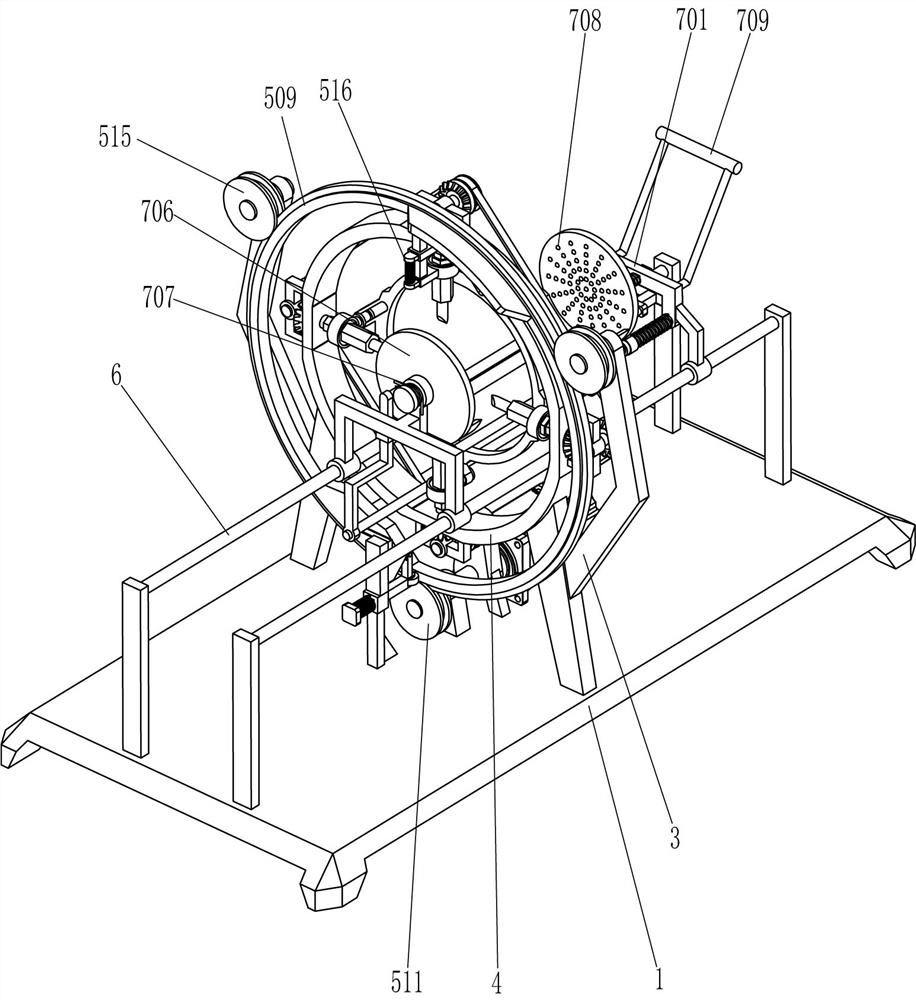

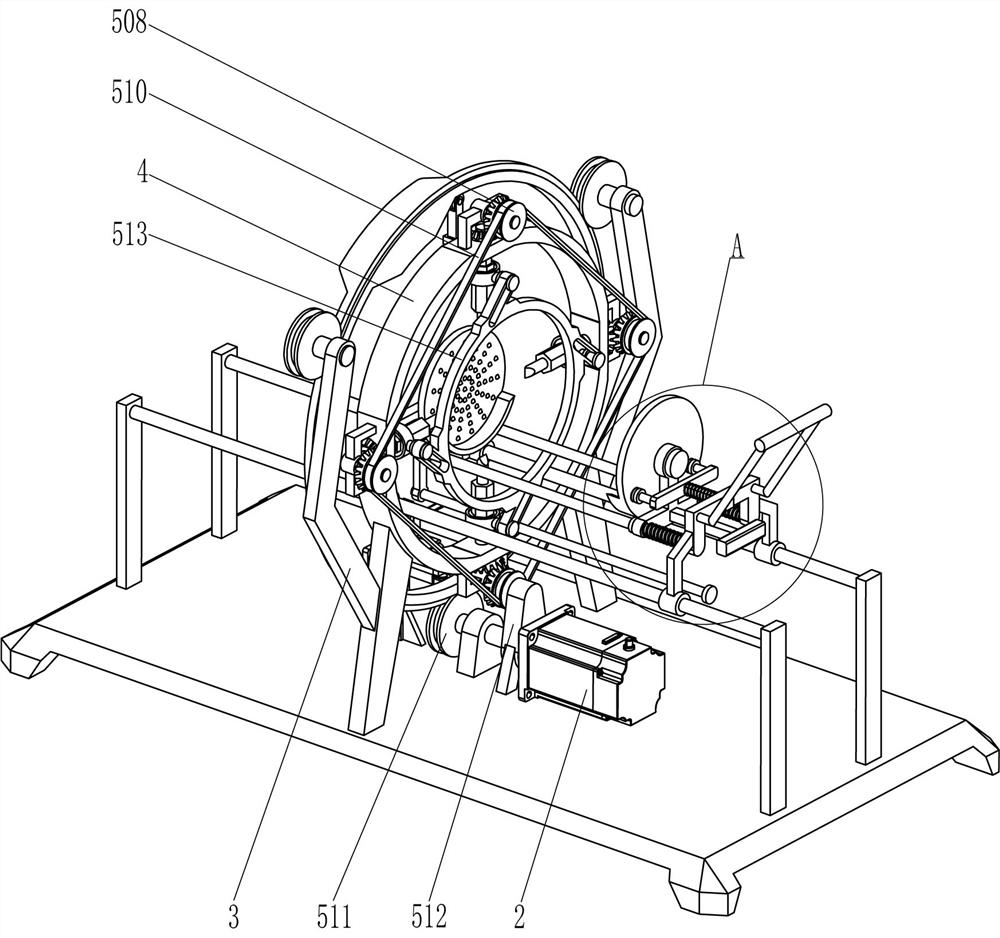

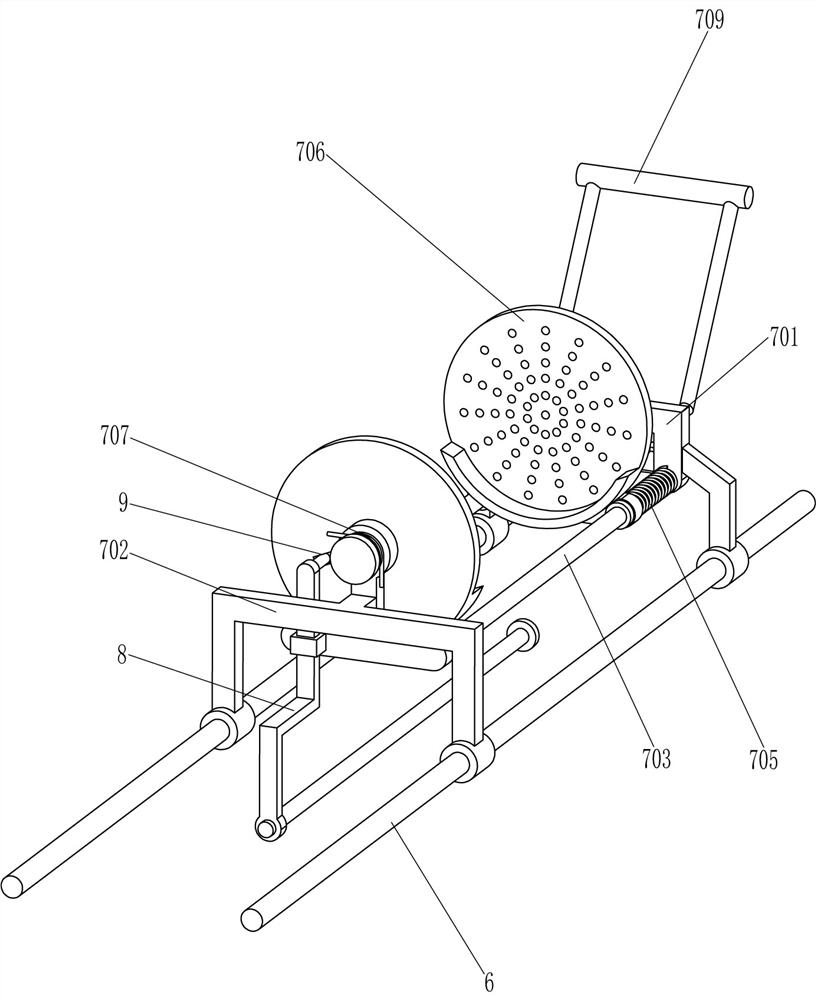

[0024] A kind of wood linden drilling equipment for agricultural production, as attached Figure 1-6 As shown, it includes a bottom plate 1, a servo motor 2, a bracket 3, a mounting frame 4, a drilling assembly 5, a guide rod 6, and a moving assembly 7. The servo motor 2 is installed in the middle of the top of the bottom plate 1 through bolts, and the front and rear sides of the top of the bottom plate 1 are Both brackets 3 and guide rods 6 are installed, two guide rods 6 are located between the two brackets 3, a circular installation frame 4 is connected between the two brackets 3, and the two guide rods 6 pass through the installation frame 4. The drilling assembly 5 is installed on the installation frame 4, and the moving assembly 7 is installed on the guide rod 6.

[0025] When needing to carry out drilling to linden, people fix linden on mobile assembly 7, then start servomotor 2 work, servomotor 2 drives drilling assembly 5 work, and drilling assembly 5 carries out dril...

Embodiment 2

[0031] On the basis of embodiment 1, as attached figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, it also includes a special-shaped rod 8, a first wedge block 10, a support sleeve 11, a contact rod 12, a second wedge block 13 and a second spring 14, and the left side of the second support frame 702 is provided with a special-shaped There is a chute 9 on the left side of the rod 8 and the left side of the placement plate 706, and the chute 9 is slidingly matched with the special-shaped rod 8. The upper part of the left side of the rotating frame 509 is connected with the first wedge block 10, and the middle of the top of the bottom plate 1 is connected with a support sleeve. 11. The support sleeve 11 is located on the left side of the gearbox 512. The contact rod 12 is slidingly provided in the support sleeve 11. The rotating frame 509 is in contact with the contact rod 12. The contact rod 12 is covered with a second spring 14. The second spring 14 The left end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com