Desulfurization and denitration powder preheating gas generator and corresponding powder boiler

The technology of denitration powder and generator is applied in the field of denitration powder preheating gas generator and corresponding powder boiler, and desulfurization field, which can solve the problems of small operation elastic space, easy to run material, difficult to maintain, etc., so as to improve the operation flexibility. The effect of stability, large operating flexibility, and improved combustion reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

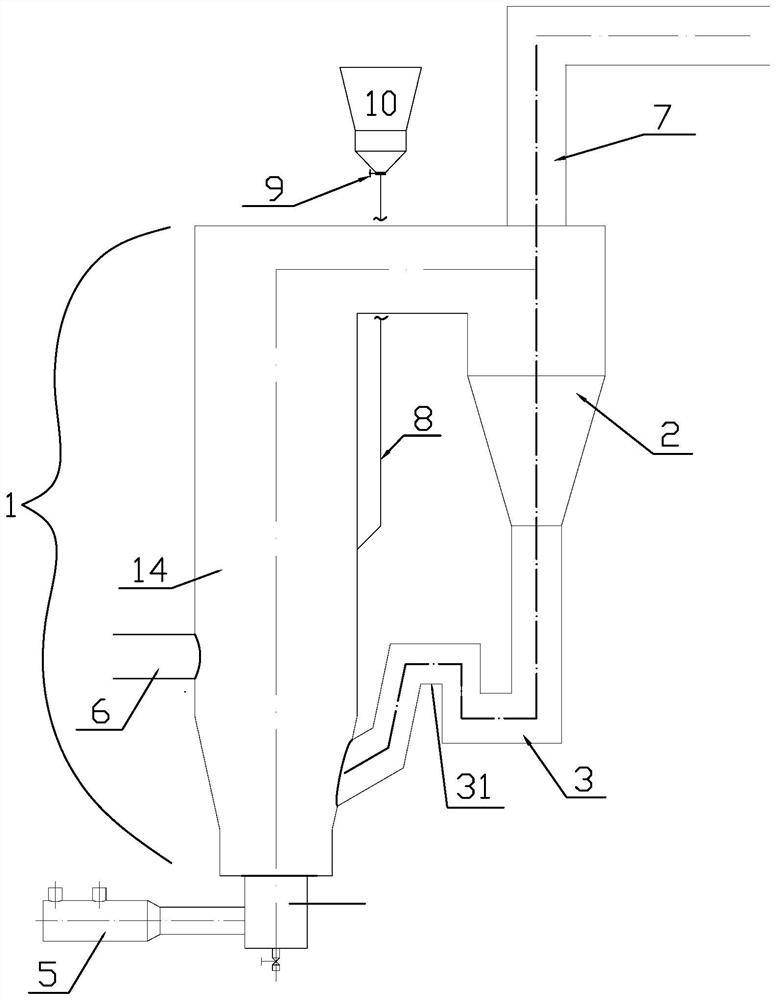

[0042] Implementation mode one: if figure 1 As shown, the desulfurization and denitrification powder preheating gas generator of the present invention includes a preheating combustion chamber 1, a gas-solid separator 2 and a feeder 3. The pipes 5 are connected, and the gas-solid separator 2 is a cyclone separator structure. The gas-solid separator 2 is provided with an inlet, a lower solid outlet and a top gas outlet. The lower side wall of the preheating combustion chamber 1 is provided with fuel powder Feed pipe 6, one side of the bottom of the preheating combustion chamber 1 communicates with the lower opening of the feeder 3, the inlet of the gas-solid separator 2 communicates with the top of the preheating combustion chamber 1, and the solids in the lower part of the gas-solid separator 2 The outlet communicates with the upper opening of the feeder 3, and the gas outlet at the top of the gas-solid separator 2 is connected with a gas outlet pipe 7. The feeder 3 is composed...

Embodiment approach 2

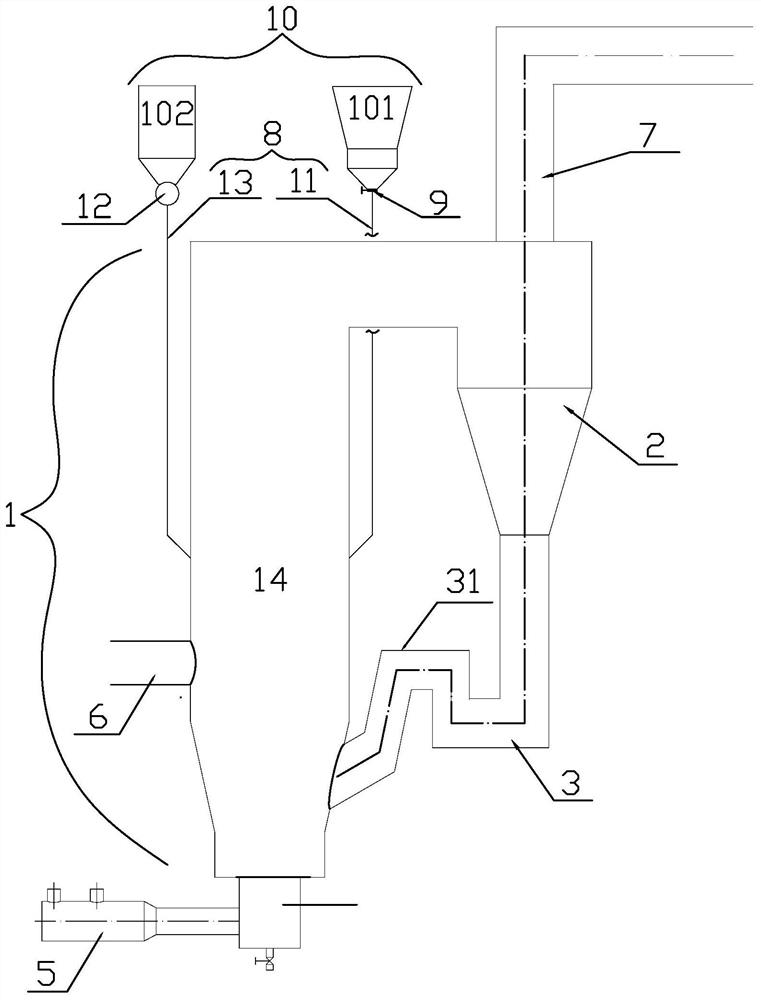

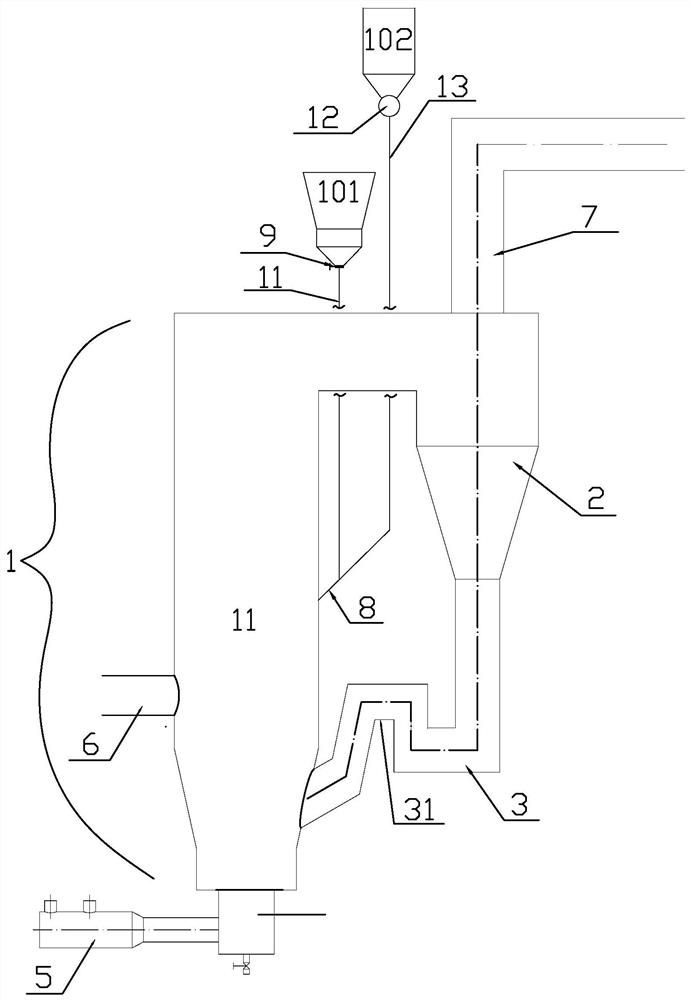

[0044] Embodiment 2: The hopper 10 includes a sand hopper 101 and a desulfurizer hopper 102. The lower port of the sand hopper 101 is provided with a feed valve 9, and communicates with a sand pipe 11 through the feed valve 9. The desulfurizer The lower mouth of the bucket 102 is provided with a screw feeder 12, and through the screw feeder 12, it communicates with a desulfurizer pipe 13, and the sand feeding pipe 11 and the desulfurizer pipe 13 are respectively used as the feed pipe 8 and passed into the preheating combustion chamber 1, Such as figure 2 shown; or the sand pipe 11 and the desulfurizer pipe 13 pass into the feed pipe 8 jointly, and pass into the preheating combustion chamber 1 through the feed pipe 8, as image 3 As shown, other structures are as described in Embodiment 1, and are omitted.

Embodiment approach 3

[0045] Implementation mode three: if Figure 4 As shown, the middle and lower part of the preheating combustion chamber 1 is provided with a fluidized bed 14 structure, and the upper part of the preheating combustion chamber 1 is also provided with a top sealing plate 111, an enlarged shell 112 and an inverted cone tubular transition section 113. The enlarged housing 112 is cylindrical, and its top side wall is provided with an air outlet groove 114. The outer edge of the top sealing plate 111 is welded on the upper edge of the expanded housing 112 and the upper edge of the air outlet groove 114 side wall. The plate 111 and the air outlet groove 114 form an air outlet, and communicate with the inlet of the gas-solid separator 2 through the air outlet, and the lower edge of the enlarged shell 112 is welded on the outer edge of the large end of the inverted cone-shaped transition section 113. The outer edge of the small end of the inverted cone-shaped transition section 113 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com