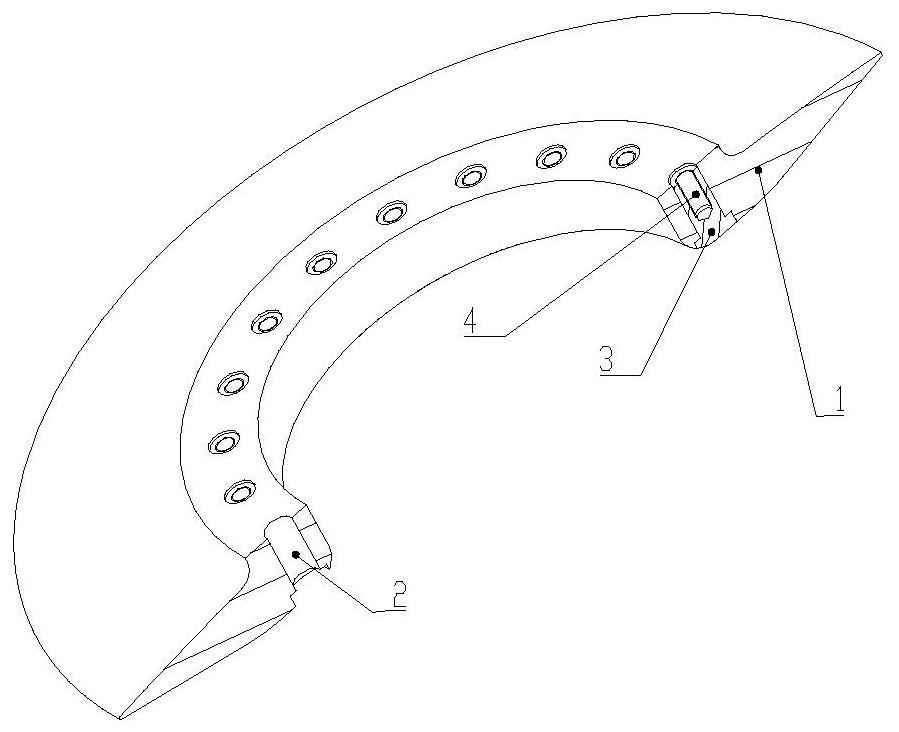

Connecting structure of composite material joint

A composite material and connection structure technology, applied in the direction of connection components, threaded fasteners, nuts, etc., can solve the problems of thread damage, thread load, etc., to avoid wear resistance, strong bearing capacity, and avoid low thread strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

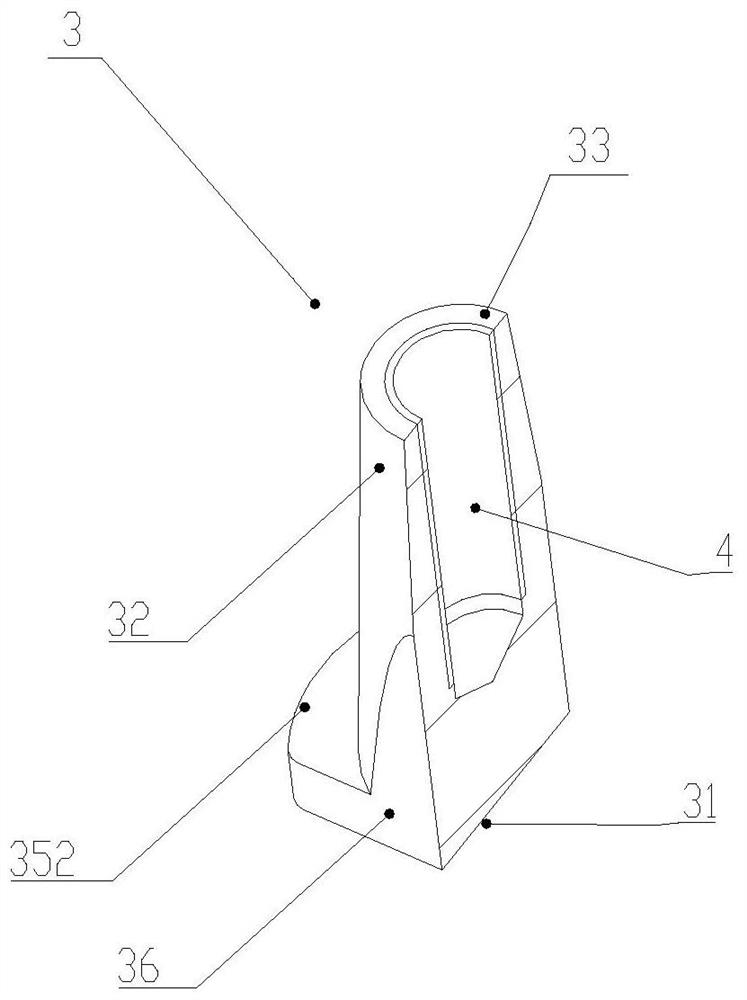

Embodiment 1

[0049] The metal insert 3 adopts a step-shaped metal insert, which is pre-embedded in the composite material joint with a flange thickness of 20mm. The metal insert 3 is made of high-strength alloy steel 30CrMnSi, and the metal insert 3 is processed with M18 threaded holes. The diameter is 28mm, the outer diameter of the limiting step is 35mm, the height of the cylinder 34 is 15mm, the height of the limiting step is 5mm, and the pull-out bearing capacity of the metal insert 3 is 17.2t.

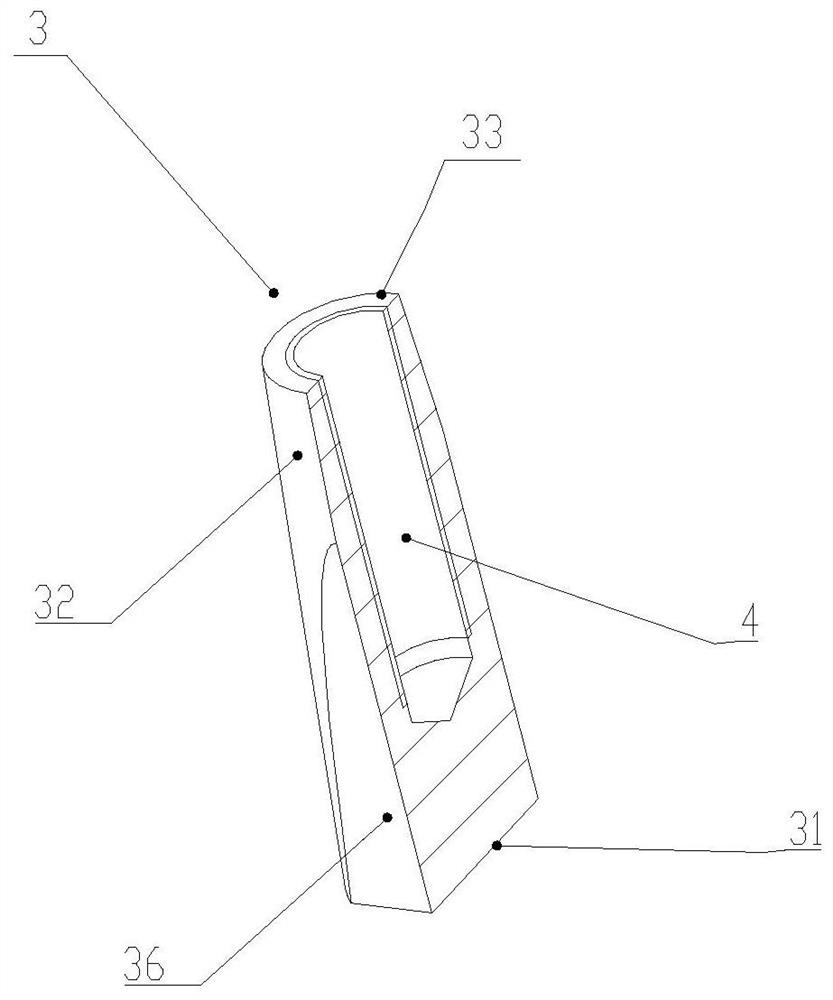

Embodiment 2

[0051] The metal insert 3 adopts a tapered metal insert, which is pre-embedded in the composite material joint with a flange thickness of 20mm. The metal insert 3 is made of high-strength alloy steel 30CrMnSi. The height of the piece 3 is 20mm, wherein, the outer diameter of the small end is 28mm, the outer diameter of the big end is 35mm, and the drawing bearing capacity of the metal insert 3 is 20.0t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com