Cutting equipment for machining

A technology of cutting equipment and mechanical processing, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low precision, hidden safety hazards, time-consuming and labor-intensive problems, and achieve the effect of increasing applicability and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

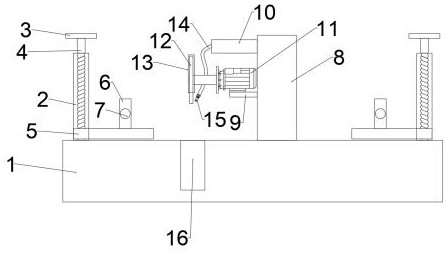

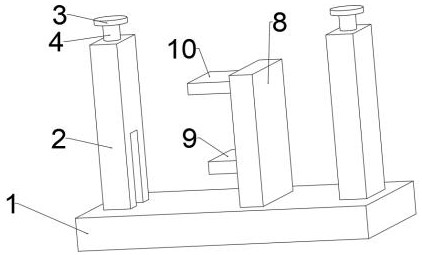

[0030] refer to Figure 1 ~ Figure 3 , a cutting device for mechanical processing, comprising a base plate 1, a first fixing plate 2 is bolt-connected to the left and right sides of the top of the base plate 1, and a first screw rod 4 is connected to the inside of the first fixing plate 2 for rotation, and the first screw rod 4 runs through the upper shell wall of the first fixed plate 2, the end of the first screw rod 4 away from the bottom plate 1 is bolted to the rotating disk 3, the bearing on the first screw rod 4 is connected to the sliding plate 5, and the sliding plate 5 runs through the first fixed plate The side shell wall of the plate 2 close to the center, the upper bolt of the sliding plate 5 is connected with the connecting plate 6, the connecting plate 6 is concave, and the front center of the connecting plate 6 is connected with the adjustment shaft 17 in rotation, and the adjusting shaft 17 runs through the connecting plate 6 On the front side shell wall, the ...

Embodiment 2

[0037] refer to Figure 4 , a kind of cutting equipment for mechanical processing. Compared with Embodiment 1, the present embodiment is provided with a traveling mechanism under the bottom plate 1. The traveling mechanism includes a rolling wheel 27 and a brake plate 28. The bottom four corners of the bottom plate 1 are bolted with rolling Wheel 27, the rolling wheel 27 is bolt-connected with brake plate 28, utilizes rolling wheel 27 to make the device can move freely, and facilitates the return of the device and misappropriation, utilizes the brake plate 28 to keep the device stable when moving the designated position, making it It will not move during operation, ensuring its use effect and increasing its applicability.

[0038] Working principle: use the rolling wheel 27 to make the device move freely, which is convenient for returning and embezzling the device, and use the brake plate 28 to keep the device stable when moving to the designated position, so that it will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com