A kind of solid needle type water storage

A water reservoir and needle-type technology, which can be applied to devices that apply liquid to surfaces, coatings, pre-treatment surfaces, etc., can solve problems such as destroying the surface quality of electrophoresis or baking paint, and achieve the effect of improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

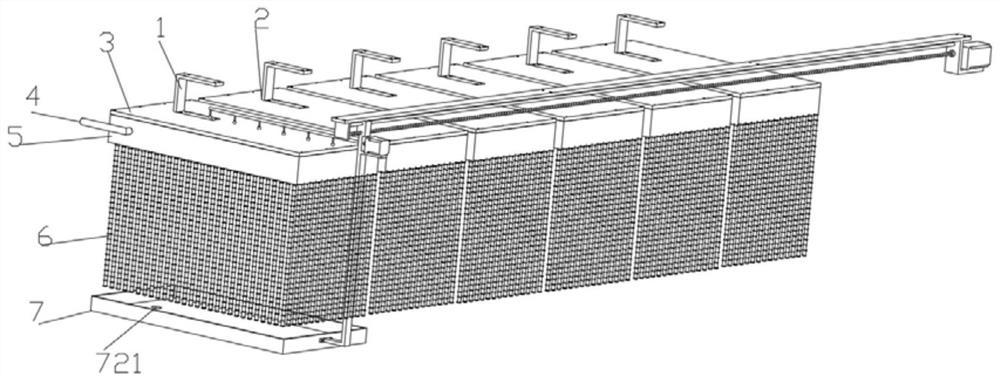

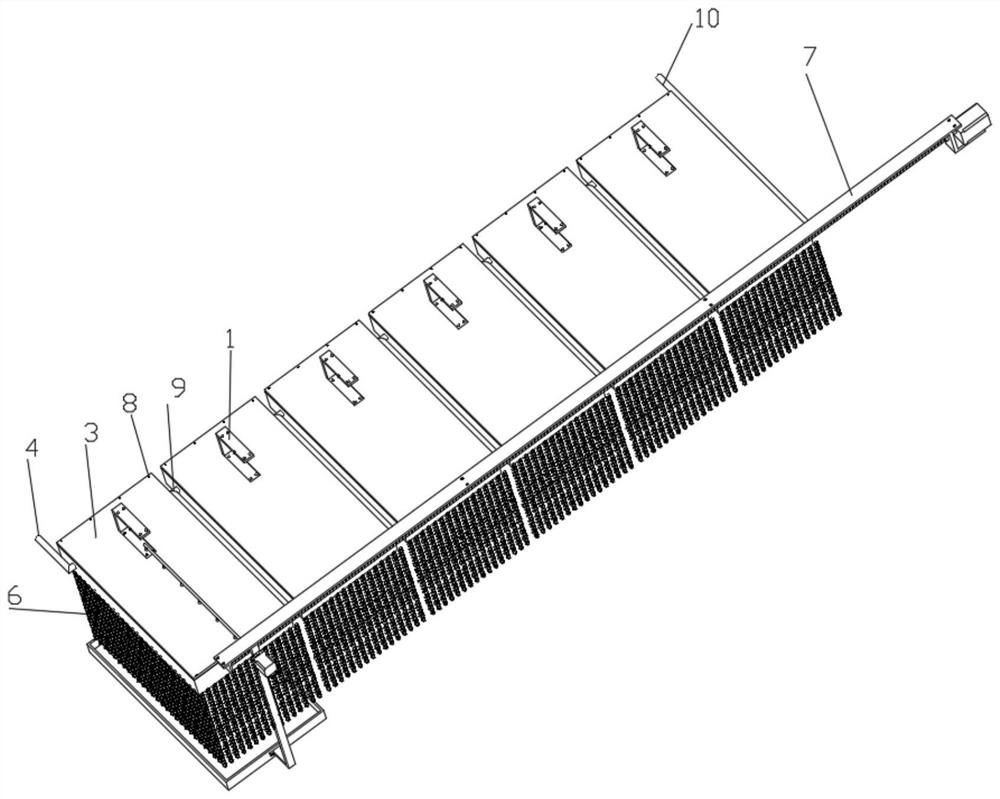

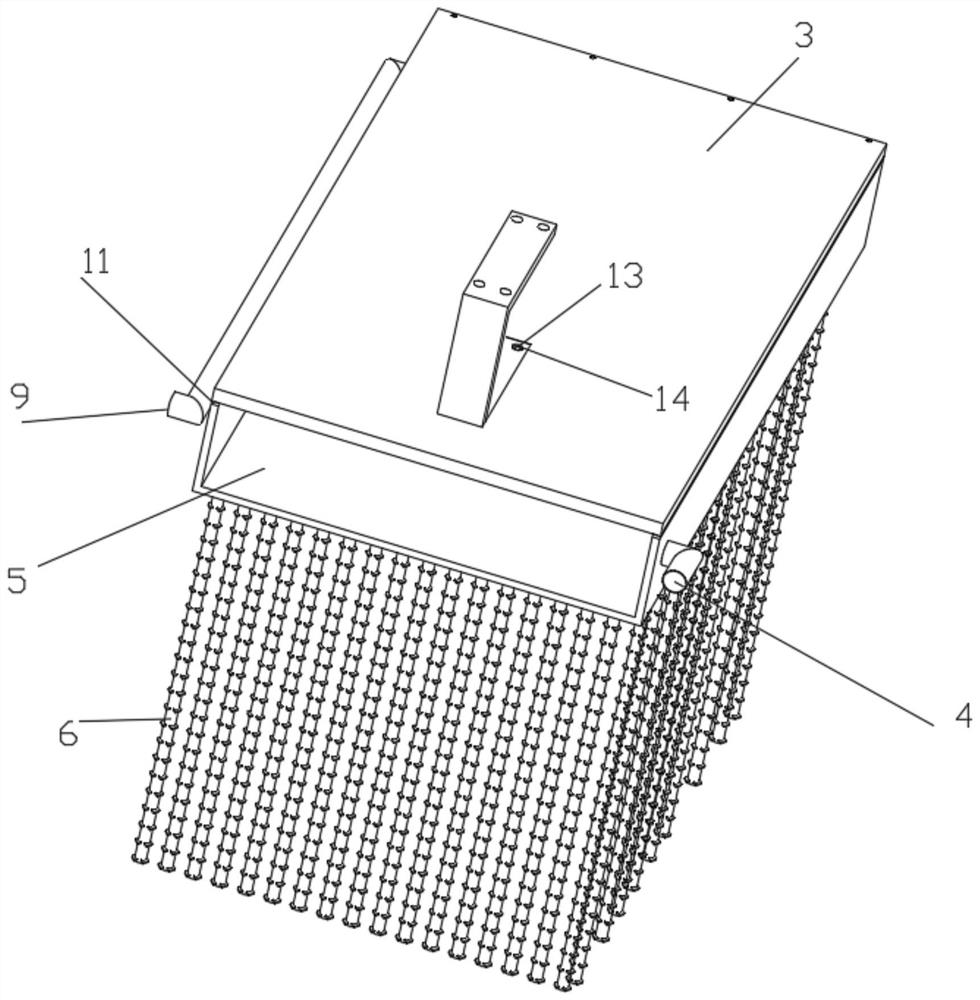

[0032] Such as Figure 1-6A solid needle-type water storage device is shown, including a C-shaped mounting frame 1 and a drainage structure 7. The bottom lateral part of the C-shaped mounting frame 1 is provided with a mounting hole 14, and the mounting hole 14 is rotatably connected with a third fixing hole. Bolt 13, the bottom of the third fixing bolt 13 is threadedly connected with the cover plate 3, the top of the cover plate 3 is provided with a straight groove 2, the bottom of the C-shaped mounting frame 1 is installed in the straight groove 2, and the bottom of the third fixing bolt 13 is connected with the straight groove 2. The bottom of the groove 2 is threaded, the bottom of the cover plate 3 is connected with a cooling structure, and the matrix at the bottom of the cooling structure is evenly fixed and connected with a fixed pin 6. The fixed pin 6 is made of a light-weight aluminum alloy with thermal conductivity, and the diameter of the fixed pin 6 is less than It...

Embodiment 2

[0034] Embodiment 2 is a further improvement to Embodiment 1.

[0035] Such as Figure 1-6 A solid needle-type water storage device shown includes a C-shaped mounting frame 1 and a drain structure 7. The bottom lateral part of the C-shaped mounting frame 1 is provided with a mounting hole 14, and a third mounting hole 14 is rotatably connected to it. Fixing bolts 13, the bottom of the third fixing bolt 13 is threadedly connected with a cover plate 3, the bottom of the cover plate 3 is connected with a cooling structure, the matrix at the bottom of the cooling structure is evenly fixed and connected with fixing pins 6, and the right end of the C-shaped mounting frame 1 is set on the right side. There is a drainage structure 7 for fixing the needle 6 to receive water. The drainage structure 7 includes a knocking structure, a first straight plate 74, a top plate 75, a sliding plate 76, a support rod 77, a first bearing 78, a first drive motor 79, a first An L-shaped plate 710, a...

Embodiment 3

[0037] Embodiment 3 is a further improvement to Embodiment 1.

[0038] Such as Figure 1-6 A solid needle-type water storage device shown includes a C-shaped mounting frame 1 and a drain structure 7. The bottom lateral part of the C-shaped mounting frame 1 is provided with a mounting hole 14, and a third mounting hole 14 is rotatably connected to it. Fixing bolts 13, the bottom of the third fixing bolt 13 is threadedly connected with a cover plate 3, the bottom of the cover plate 3 is connected with a cooling structure, the cooling structure includes an outlet pipe 4, a water tank 5, a second fixing bolt 8, an intermediate pipe 9, and a water inlet pipe 10 and gasket 11, the top of the water tank 5 is fixedly connected with a gasket 11, the water tank 5 is connected to the cover plate 3 through the gasket 11, and the water tank 5 and the cover plate 3 are threadedly connected with a second fixing bolt 8 through a threaded hole. Adjacent water tanks 5 are fixedly connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com