Preparation method of sandwich-shaped heterostructured MOF having multiple amino functional groups used for efficiently separating C2H2/CH4

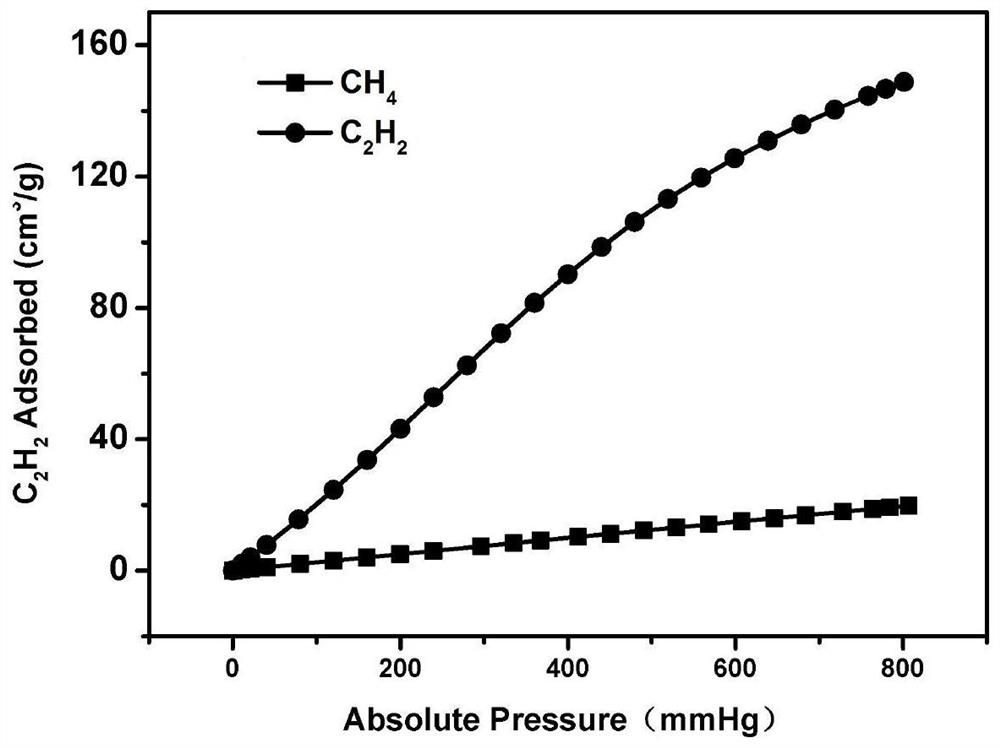

A polyamino-functional, C2H2 technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve good application prospects, simple steps, and improved gas selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1: 0.059g Liuheshui zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 0.033g terephthalic acid, 0.011g 1,4-diazabicyclooctane were placed in a 10ml DMF beaker and ultrasonically dissolved for 10 minutes, and then moved to a polytetrafluoroethylene reactor at 120°C for reaction In two days, transparent seed crystal A was obtained;

[0028] S2: Filter the transparent MOF crystal A obtained in the previous step, and then move the crystal A to dichloromethane (CH 2 Cl 2 ) in the solution for 60 minutes for solvent exchange, filtered, and vacuum activated at 30°C to obtain activated MOF seed crystal A;

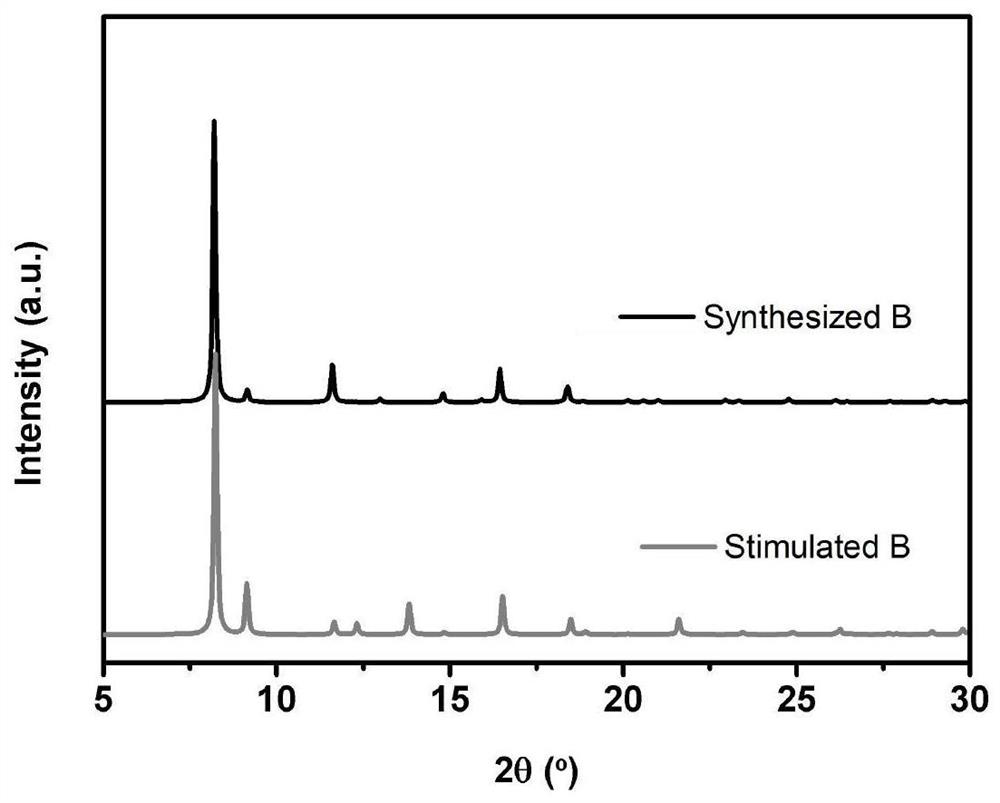

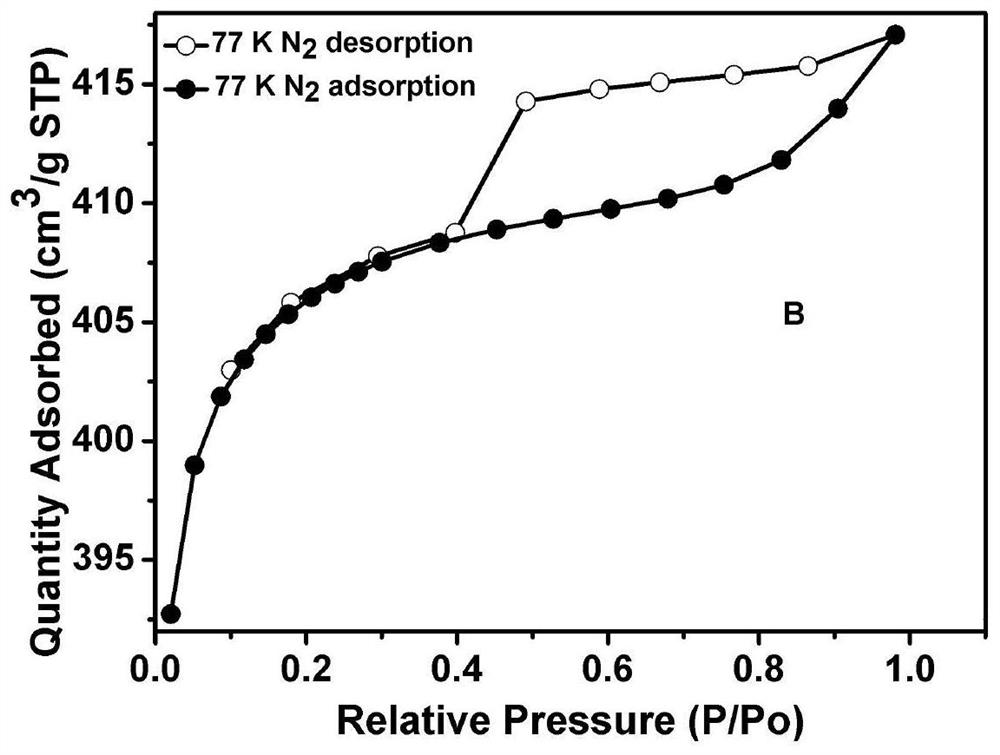

[0029] S3: 0.059g Liuheshui zinc nitrate (Zn(NO 3 ) 2 ·6H 2(2), 0.041g 2,3,5,6-tetraaminoterephthalic acid, 0.011g 1,4-diazabicyclooctane were added into a 8ml DEF beaker and ultrasonically dissolved for 3 minutes, then it was transferred To a polytetrafluoroethylene reactor, add 0.01 mmol of the activated MOF seed crystal A obtained in the previous step, and react at 120°C for t...

Embodiment 2

[0033] S1: 0.059g Liuheshui zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 0.033g terephthalic acid, 0.011g 1,4-diazabicyclooctane were placed in a 10ml DMF beaker and ultrasonically dissolved for 10 minutes, and then moved to a polytetrafluoroethylene reactor at 120°C for reaction Two days later, the activated MOF seed crystal A was obtained;

[0034] S2: The transparent crystal A obtained in the previous step is filtered, and then the crystal A is moved to dichloromethane (CH 2 Cl 2 ) in the solution for 60 minutes for solvent exchange, filtered, and vacuum activated at 30°C to obtain activated MOF seed crystal A;

[0035] S3: 0.059g Liuheshui zinc nitrate (Zn(NO 3 ) 2 ·6H 2 (2), 0.041g 2,3,5,6-tetraaminoterephthalic acid, 0.022g 1,4-diazabicyclooctane were added into a 8ml DEF beaker and ultrasonically dissolved for 3 minutes, then it was transferred To a polytetrafluoroethylene reactor, add 0.01 mmol of the activated MOF seed crystal A obtained in the previous step, and react...

Embodiment 3

[0038] S1: 0.059g Liuheshui zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 0.033g terephthalic acid, 0.011g 1,4-diazabicyclooctane were placed in a 10ml DMF beaker and ultrasonically dissolved for 10 minutes, and then moved to a polytetrafluoroethylene reactor at 120°C for reaction Two days later, the activated MOF seed crystal A was obtained;

[0039] S2: The transparent crystal A obtained in the previous step is filtered, and then the crystal A is moved to dichloromethane (CH 2 Cl 2 ) in the solution for 60 minutes for solvent exchange, filtered, and vacuum activated at 30°C to obtain activated MOF seed crystal A;

[0040] S3: 0.059g Liuheshui zinc nitrate (Zn(NO 3 ) 2 ·6H 2 (2), 0.041g 2,3,5,6-tetraaminoterephthalic acid, 0.006g 1,4-diazabicyclooctane were added into a DEF beaker with 8ml and ultrasonically dissolved for 3 minutes, then it was removed To a polytetrafluoroethylene reactor, add 0.01 mmol of the activated MOF seed crystal A obtained in the previous step, and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com