Chicken feed processing assembly line

An assembly line and chicken feed technology, which is applied to feed, heating devices, and dry solid materials, etc., can solve the problems of feed not being separated and filtered, feed drying speed reduced, and drying degree uneven, so as to improve the screening effect and improve Effect of drying speed and improvement of quality uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

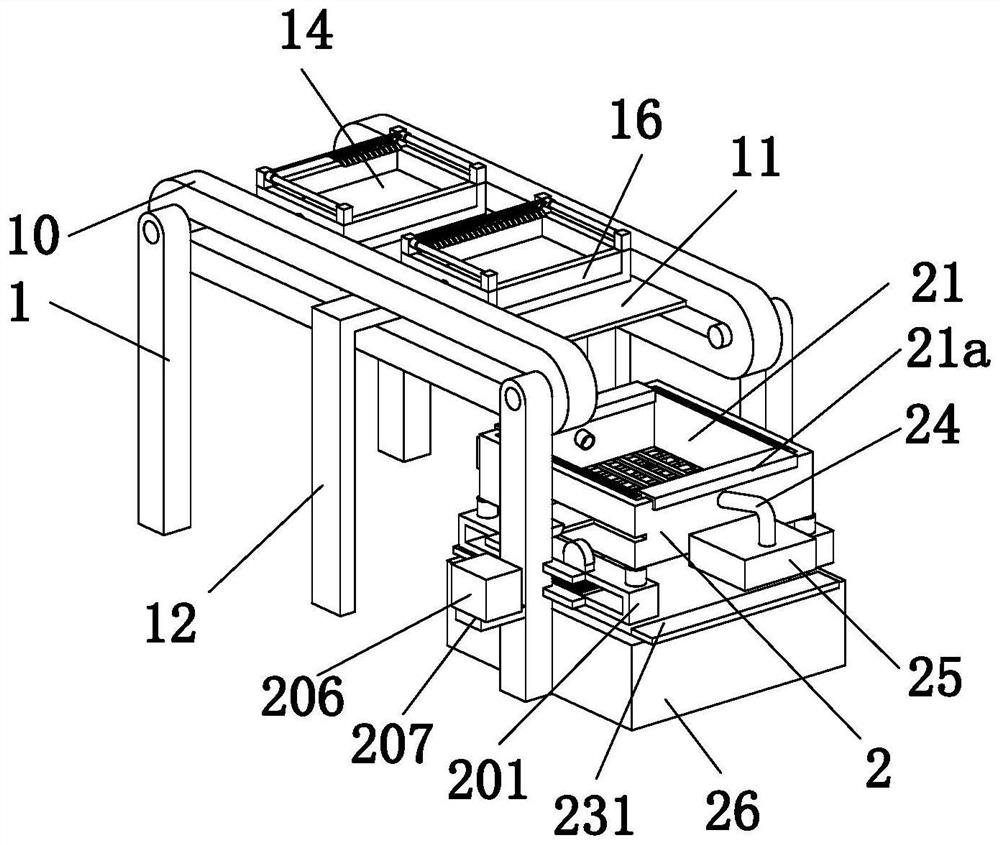

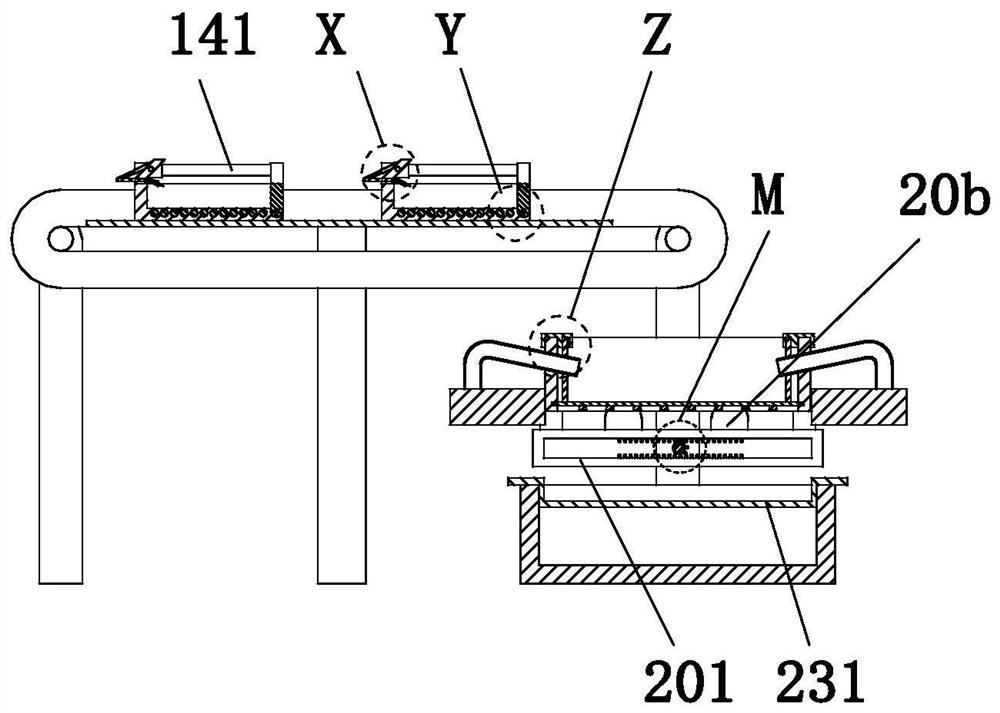

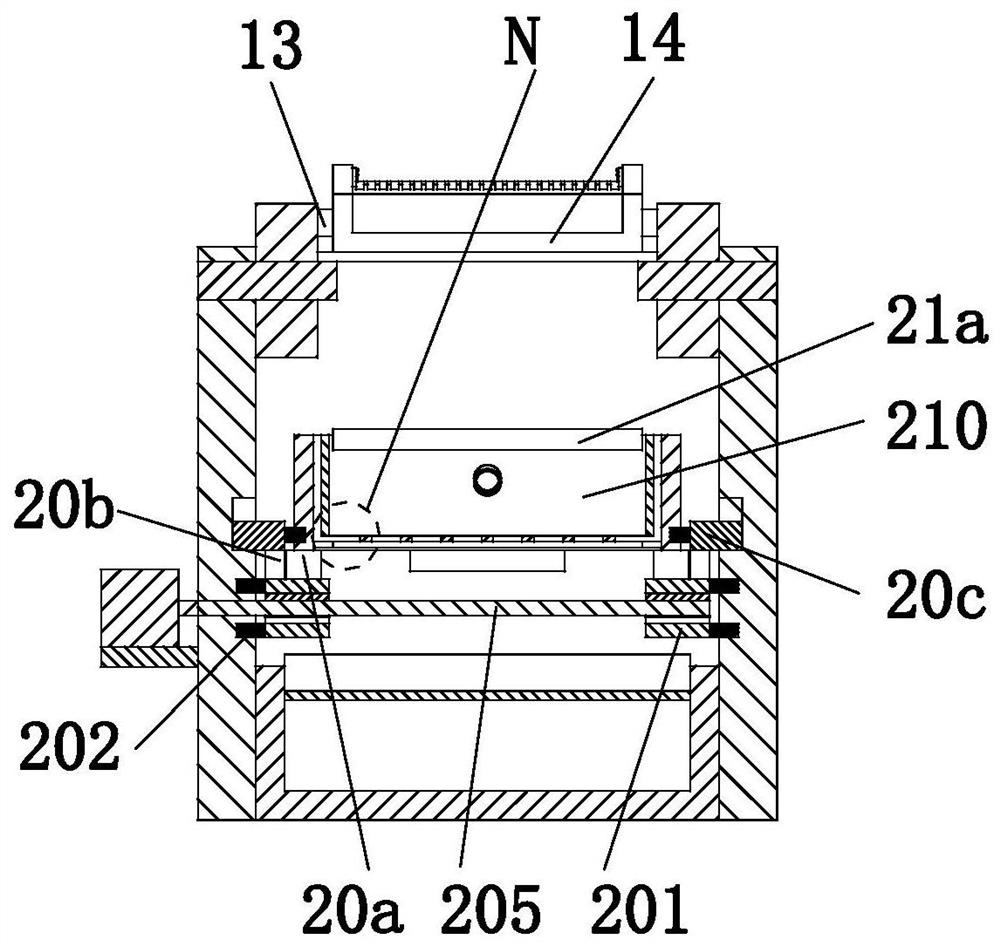

[0033] Such as Figure 1 to Figure 10 As shown, a chicken feed processing line includes an initial drying mechanism 1 and an air-drying mechanism 2. The lower end of the initial drying mechanism 1 is installed on the existing working ground, and the air-drying mechanism 2 is arranged on the right lower end of the initial drying mechanism 1.

[0034] Described preliminary drying mechanism 1 comprises belt conveyor 10, support plate 11, column 12, connecting shaft 13, drying basket 14, electric heating tube 15, dividing plate 16, connecting spring 17 and semicircle block 18, belt conveyor 10 is symmetrically installed on the existing working ground front and back, and a support plate 11 is arranged between the belt conveyors 10, and a column 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com