Net rack type soil test automatic sample separation device

A technology of geotechnical testing and net frame, which is applied in the direction of measuring devices, sampling, and analyzing materials, etc., can solve the problems of cutting speed, force size and stability, difficulty in controlling, affecting test samples, and low test efficiency, so as to improve geotechnical technology The effect of automation level, ensuring sample quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

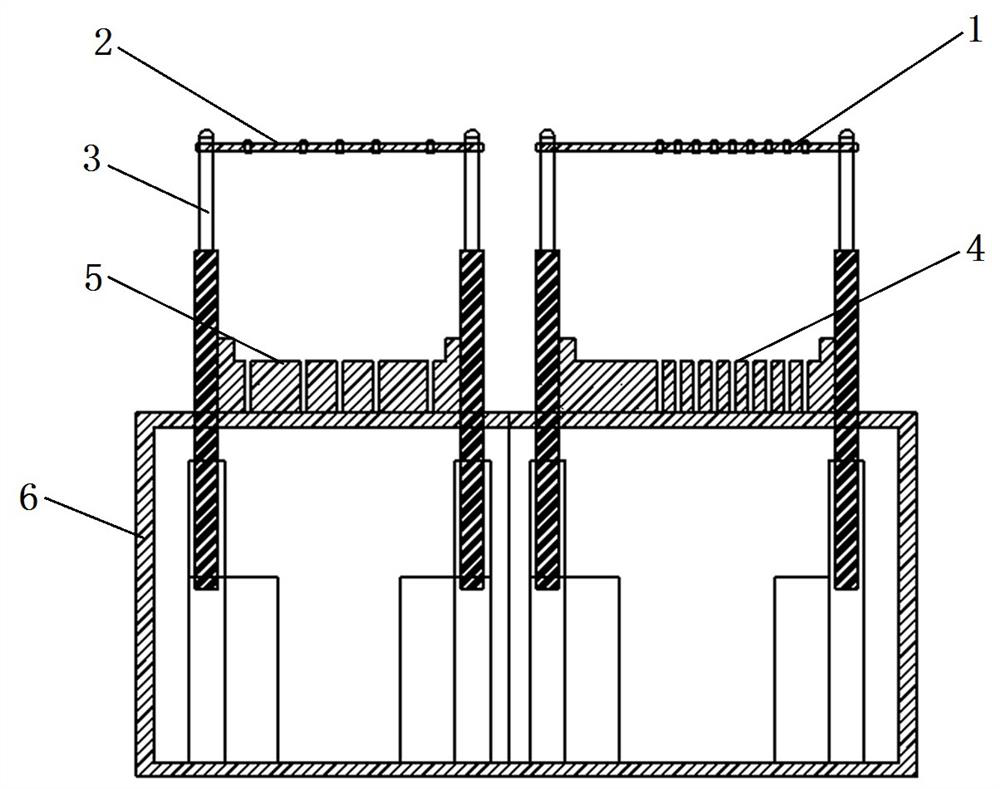

[0044] see Figure 1 to Figure 4 , a grid-type geotechnical test automatic sampling device, including steel wire cutting soil grid, electric push rod 3, combined support, control cabinet 6. The steel wire soil cutting grid frame is arranged on the top of the control cabinet 6 and is horizontally installed on the piston ends of several electric push rods 3 erected, and the fixed end of the electric push rod 3 is installed on the control cabinet 6. The combined support is installed on the top of the control cabinet 6 and corresponds up and down with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com