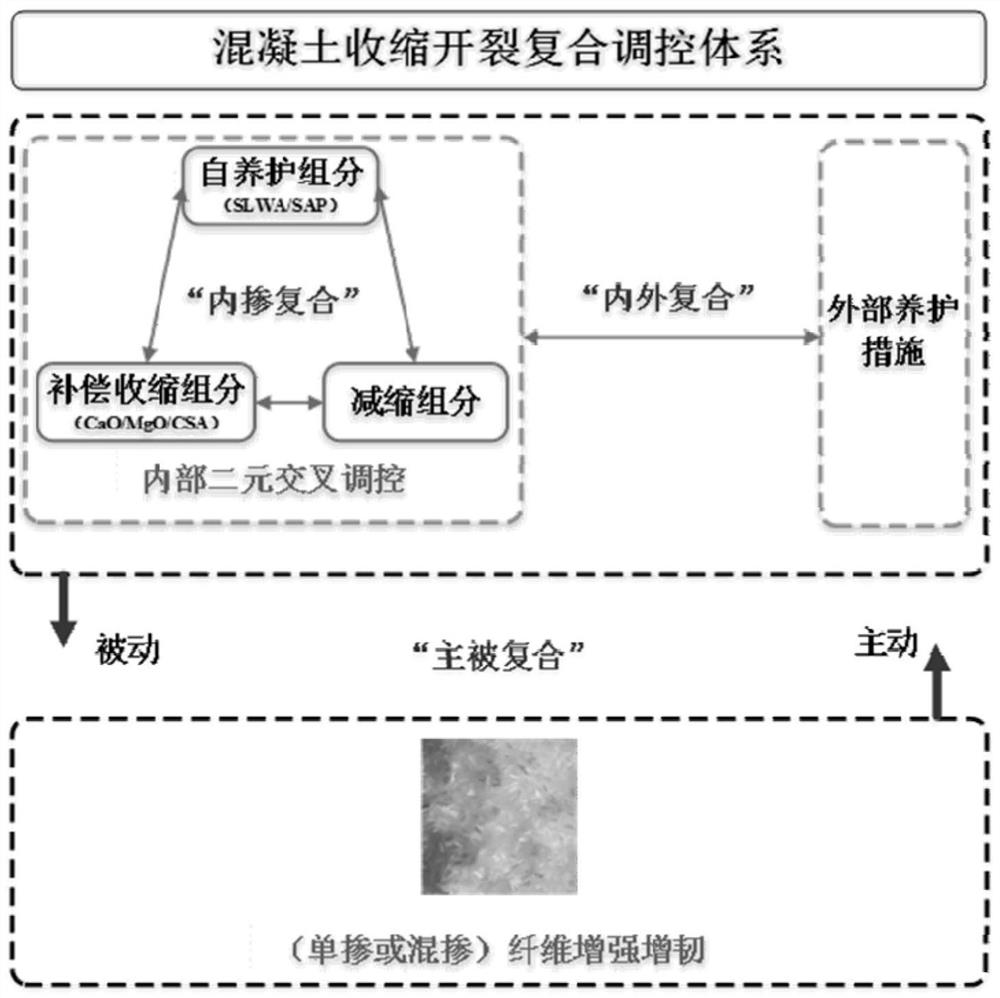

Concrete Shrinkage Crack Composite Regulation System and Regulation Method

A shrinkage cracking, concrete technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of low shrinkage cracking control efficiency, limited application scope, poor anti-cracking performance and durability of concrete, etc. Remarkable control effect, overcoming the effects of small control application range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

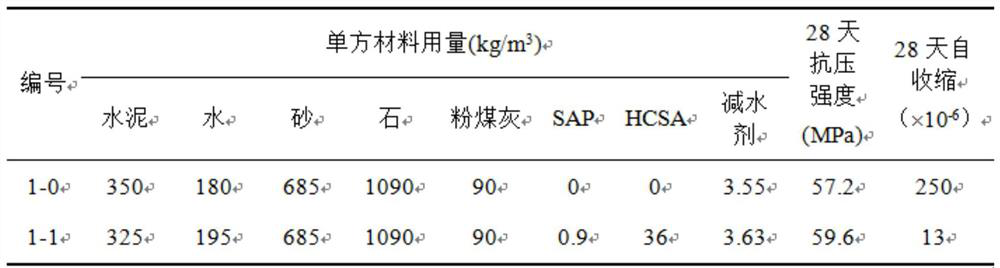

[0060] Example 1: C50 large-volume concrete is regulated by self-curing components and shrinkage-compensating components.

[0061] The self-curing component used in Example 1 is acrylic acid-acrylamide cross-linked superabsorbent copolymer (SAP), without pre-absorbing water, and the shrinkage compensating component is calcium sulfoaluminate-calcium oxide expansion agent (HCSA), and the concrete mix ratio , 28-day compressive strength (cured under the same conditions, the size of the test piece is 100mm×100mm×100mm, the same below) and 28-day self-shrinkage results are shown in Table 1, where the mix ratio numbered 1-0 is the base mix ratio, and Composite control is adopted, and the 1-1 mix ratio is the mix control ratio of the self-curing component and the compensating shrinkage component. When testing concrete shrinkage, keep the concrete specimen in a sealed state, that is, the measured concrete shrinkage is autogenous shrinkage.

[0062] In the mix ratio of Table 1, the co...

Embodiment 2

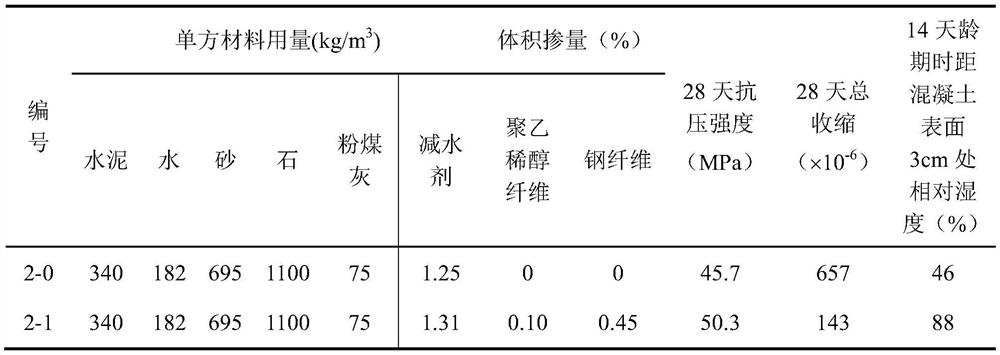

[0066] Example 2: C40 concrete in the dry and windy environment of Northwest China, adopting external maintenance measures and passive components for compound regulation.

[0067] The external curing measures used in the embodiment two are styrene-acrylic emulsion system external curing agent, and the effective curing time of the styrene-acrylic emulsion external curing agent is greater than 14 days. Curing agent; the passive component is a mixture of polyvinyl alcohol fiber (length 25mm, diameter 15μm) and steel fiber (length 30mm, diameter 1.2mm). The concrete mix ratio, 28-day compressive strength and 28-day total shrinkage results are shown in Table 2, where the number 2-0 mix ratio is the base mix ratio, no compound control is used, and the 2-1 mix ratio is the use of external curing measures Mixing ratio of compound regulation with passive components. When testing concrete shrinkage, keep the concrete specimen in a dry state on the upper surface. The measured concrete s...

Embodiment 3

[0071] Example 3: C50 concrete in perennial high-temperature and high-humidity (annual average temperature 25-30°C, RH≥85%) remote sea island and reef environment, using composite control of shrinkage compensating components and shrinkage reducing components.

[0072] The shrinkage compensating component used in embodiment three is calcium sulfoaluminate-calcium oxide expansion agent (HCSA), and the shrinkage reduction component used is polyol ether organic shrinkage reducer (SRA), concrete mix ratio, 28-day compressive strength and The 28-day total shrinkage results are shown in Table 3, wherein the number 3-0 mix ratio is the base mix ratio without compound control, and the 3-1 mix ratio is the mix ratio that uses the compound control of the compensating shrinkage component and the shrinkage reducing component . When testing concrete shrinkage, keep the concrete specimen in a dry state on the upper surface. The measured concrete shrinkage is the total shrinkage (ie, the sum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com