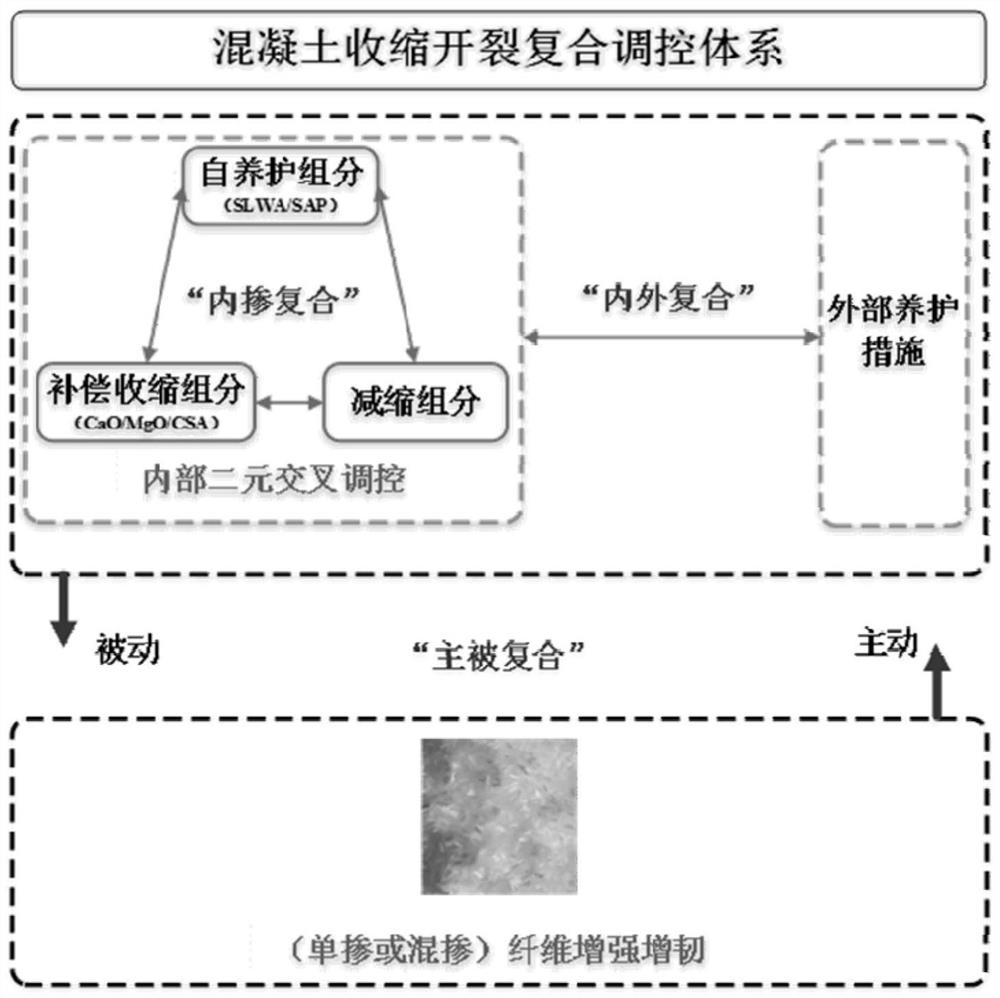

Concrete shrinkage cracking composite regulation and control system and regulation and control method

A shrinkage cracking and concrete technology, applied in construction, building material processing, building construction, etc., can solve problems such as limited application scope, low shrinkage cracking control efficiency, and poor concrete cracking resistance and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

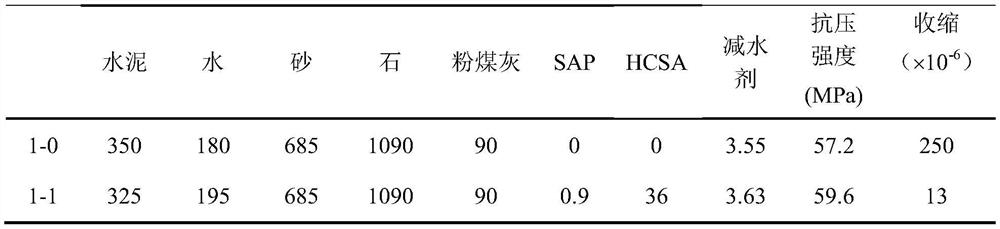

[0060] Example 1: C50 large-volume concrete is regulated by self-curing components and shrinkage-compensating components.

[0061] The self-curing component used in Example 1 is acrylic acid-acrylamide cross-linked superabsorbent copolymer (SAP), without pre-absorbing water, and the shrinkage compensating component is calcium sulfoaluminate-calcium oxide expansion agent (HCSA), and the concrete mix ratio , 28-day compressive strength (cured under the same conditions, the size of the test piece is 100mm×100mm×100mm, the same below) and 28-day self-shrinkage results are shown in Table 1, where the mix ratio numbered 1-0 is the base mix ratio, and Composite control is adopted, and the 1-1 mix ratio is the mix control ratio of the self-curing component and the compensating shrinkage component. When testing concrete shrinkage, keep the concrete specimen in a sealed state, that is, the measured concrete shrinkage is autogenous shrinkage.

[0062] In the mix ratio of Table 1, the co...

Embodiment 2

[0067] Example 2: C40 concrete in the dry and windy environment of Northwest China, adopting external maintenance measures and passive components for compound regulation.

[0068] The external curing measures used in the embodiment two are styrene-acrylic emulsion system external curing agent, and the effective curing time of the styrene-acrylic emulsion external curing agent is greater than 14 days. Curing agent; the passive component is a mixture of polyvinyl alcohol fiber (length 25mm, diameter 15μm) and steel fiber (length 30mm, diameter 1.2mm). The concrete mix ratio, 28-day compressive strength and 28-day total shrinkage results are shown in Table 2, where the number 2-0 mix ratio is the base mix ratio, no compound control is used, and the 2-1 mix ratio is the use of external curing measures Mixing ratio of compound regulation with passive components. When testing concrete shrinkage, keep the concrete specimen in a dry state on the upper surface. The measured concrete s...

Embodiment 3

[0072] Example 3: C50 concrete in perennial high-temperature and high-humidity (annual average temperature 25-30°C, RH≥85%) remote sea island and reef environment, using composite control of shrinkage compensating components and shrinkage reducing components.

[0073] The shrinkage compensating component used in embodiment three is calcium sulfoaluminate-calcium oxide expansion agent (HCSA), and the shrinkage reduction component used is polyol ether organic shrinkage reducer (SRA), concrete mix ratio, 28-day compressive strength and The 28-day total shrinkage results are shown in Table 3, wherein the number 3-0 mix ratio is the base mix ratio without compound control, and the 3-1 mix ratio is the mix ratio that uses the compound control of the compensating shrinkage component and the shrinkage reducing component . When testing concrete shrinkage, keep the concrete specimen in a dry state on the upper surface. The measured concrete shrinkage is the total shrinkage (ie, the sum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com