Tunnel construction method for short-tube-joint immersed tube

An immersed tube tunnel and construction method technology, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve problems such as high requirements for continuous supply capacity of concrete, long and large volume of immersed tubes, and difficulty in loading barges on immersed tubes , to achieve the effect of reducing configuration requirements and application environment requirements, reducing water depth requirements, and improving prefabrication efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

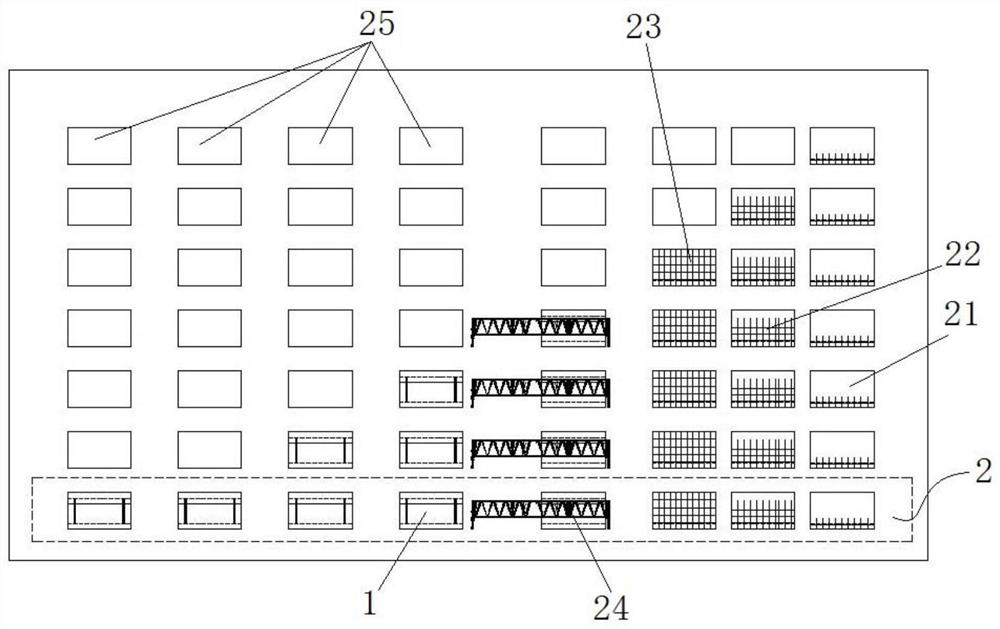

[0044] Such as Figure 1-5 As shown, in this embodiment, a construction method for a short-section immersed-pipe tunnel is provided, which mainly includes the following steps:

[0045] S10. Immersed tube prefabrication:

[0046] The immersed tube 1 is prefabricated in line 2 type, including four parts: steel bar binding, formwork installation, concrete pouring and outfitting; wherein, the concrete pouring is a one-time molding to realize the non-layered and divided parts of the immersed tube 1. section and without construction joints, to reduce the risk of cracking of the immersed tube 1, the length of the immersed tube 1 after forming is 20-30m. In this embodiment, the length of the immersed tube 1 is 22m, so that the immersed tube The size control of the tunnel pipe section meets the self-floating requirements of the single-section immersed pipe 1 at the same time, reducing the difficulty of installation and construction.

[0047] Further, there are several assembly lines ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com