Gold foil dicing device

A technology of dicing and gold foil, applied in metal processing and other directions, can solve the problems of cumbersome, time-consuming, and low efficiency of square blocks, and achieve the effect of improving efficiency and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

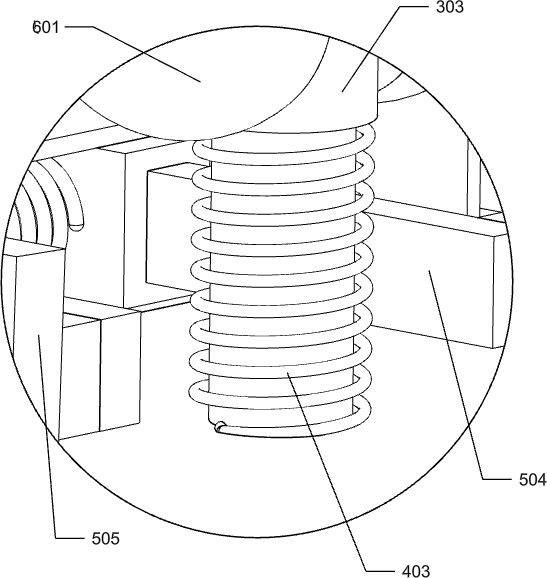

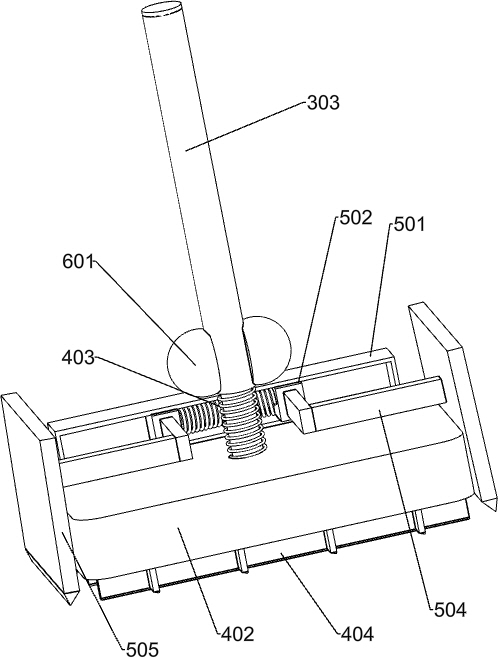

[0025] A gold leaf dicing device such as Figure 1-5 As shown, it includes a mounting frame 1, a placement plate 2, a swing mechanism 3 and a buffer mechanism 4. A placement plate 2 is connected between the tops of the mounting frame 1. The number of placement plates 2 is one, and a swing is installed on the rear side of the top of the placement plate 2. Mechanism 3, a buffer mechanism 4 is connected to the bottom of the swing mechanism 3.

[0026] When the worker needs to cut the gold leaf, the worker needs to put a piece of gold leaf on the sponge placement block body 7 first. The rotation will drive the buffer mechanism 4 to move downward, and the downward movement of the buffer mechanism 4 will cut the gold foil on the sponge placement block body 7, and then the worker needs to rotate the swing mechanism 3 clockwise, and the swing mechanism 3 will move upward to reset, and the swing mechanism The upward movement of 3 will drive the buffer mechanism 4 to move upward and re...

Embodiment 2

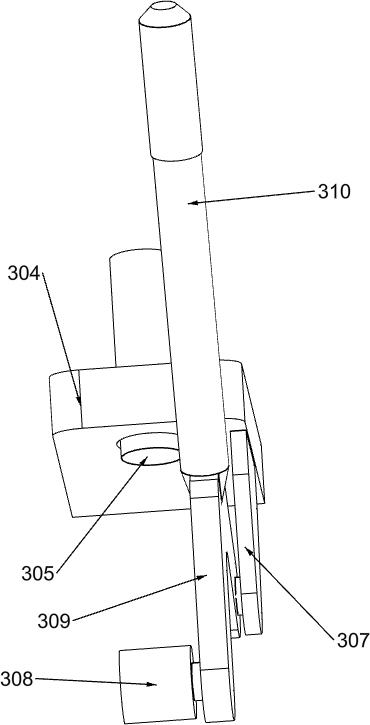

[0028] In a preferred embodiment of the present invention, as Figure 1-8 As shown, the swing mechanism 3 includes a mounting plate 301, a first guide sleeve 302, a first slide bar 303, a second guide sleeve 304, a second slide bar 305, a slide plate 306, an arc plate 307, a roller 308, and a Y-shaped pressing plate 309 And the pressure handle 310, the mounting plate 301 is welded in the middle of the top rear side of the mounting frame 1, the number of the mounting plate 301 is one, the first guide sleeve 302 is installed on the lower part of the front side of the mounting plate 301, the number of the first guide sleeve 302 is one, The first guide sleeve 302 is slidingly provided with a first slide bar 303, the number of the first slide bar 303 is one, and the upper part of the front side of the mounting plate 301 is fixedly connected with a second guide sleeve 304, and the number of the second guide sleeve 304 is One, the second slide bar 305 is provided slidingly in the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com