Working table for manufacturing clothes

A workbench and workbench technology, applied to workbenches, manufacturing tools, etc., can solve problems such as lowering work efficiency, inconvenient space occupation, and environmental pollution, so as to reduce work intensity, improve practicability, and stabilize the workbench Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

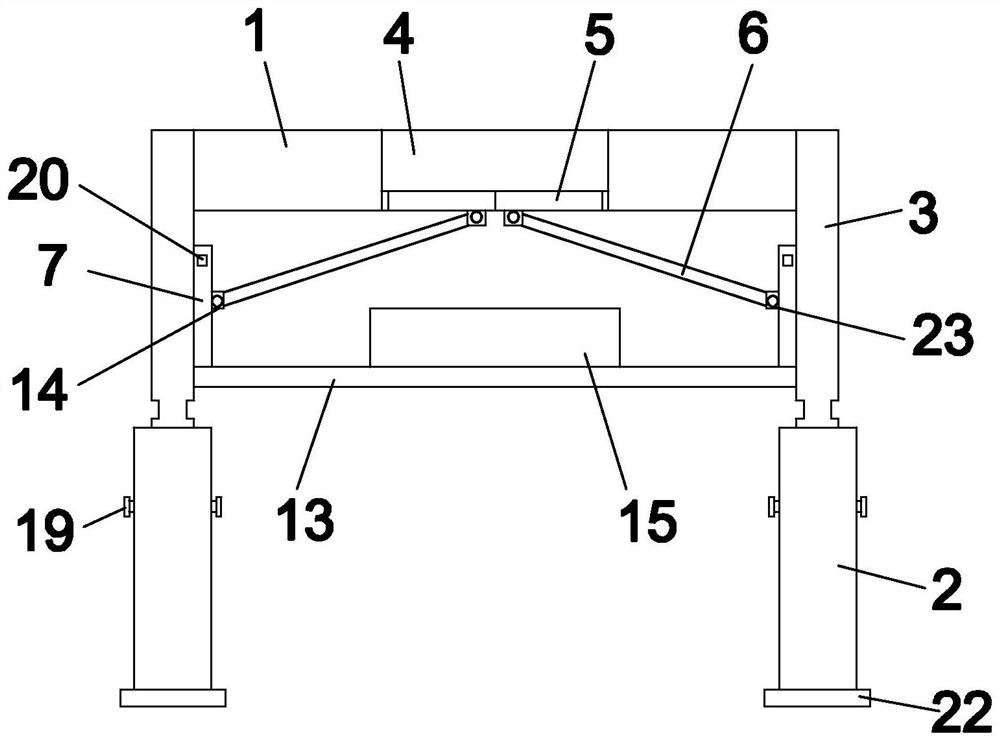

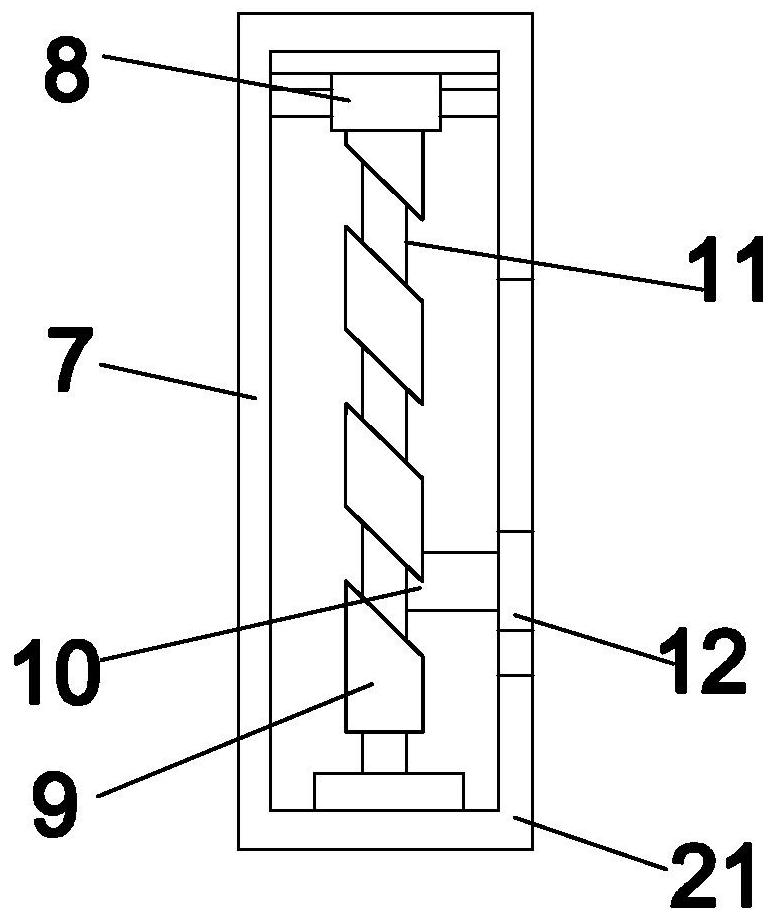

[0022] see Figure 1-3 According to an embodiment of the present invention, a workbench for making clothes includes a work platform 1, a support frame 2 is fixed on both sides of the work platform 1, and one end of the support frame 2 passes through the support frame 2 3 and Extending to the inside of the support frame 2, the working platform 1 is provided with a storage tank 4, and the bottom of the storage tank 4 is symmetrically provided with a chip baffle 5, and one end of the chip baffle 5 is connected to the inner wall of the storage tank 4 Through the movable connection of the hinge, the bottom of the chip baffle 5 is fixed with a connecting block 23, and the movable frame 6 is movably connected on the connecting block 23, and the movable frame 6 is far away from the end of the connecting block 23 and the slider 14. Flexible connection, the slider 14 side is provided with an adjustment seat 7, the adjustment seat 7 is fixedly connected with the support frame 1, the insi...

Embodiment 2

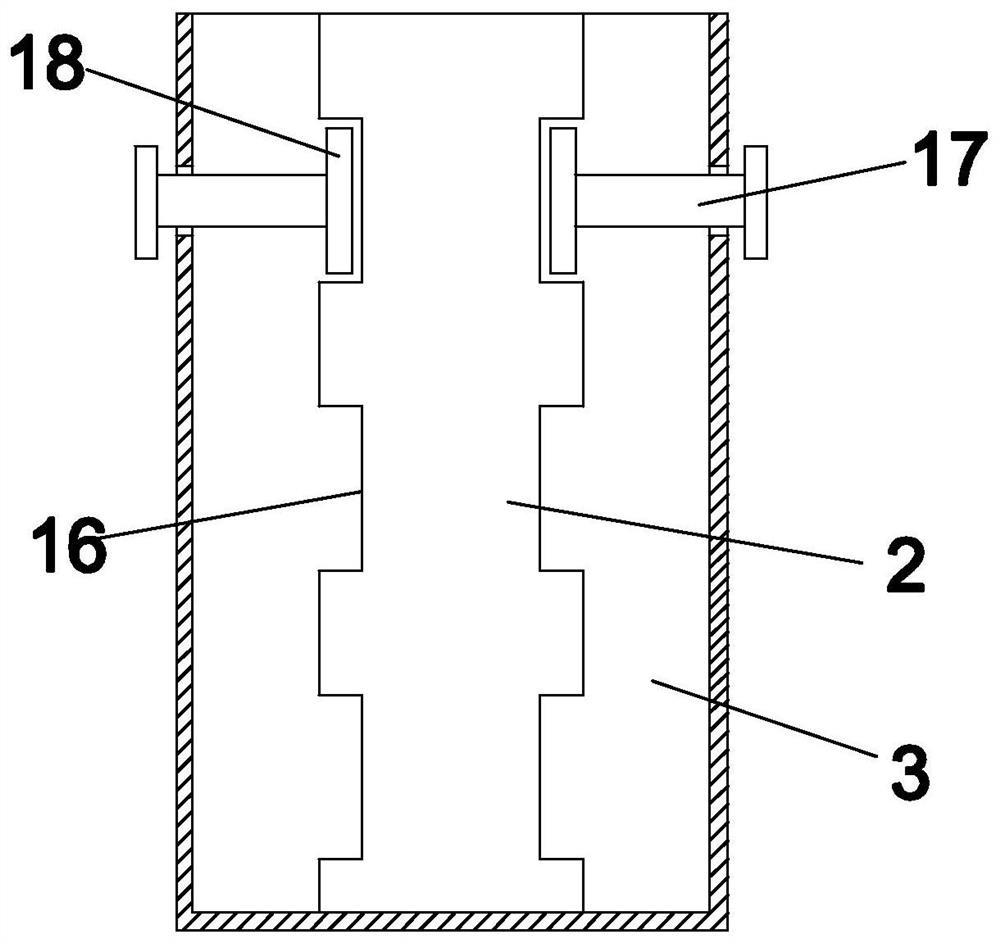

[0024] see Figure 1-3 , for the support frame two 3, the bottom of the support frame two 3 is provided with a rubber pad 22, by being provided with the rubber pad 22, it plays the role of anti-skid and wear resistance, making the workbench more stable. For the support frame one 2, the two sides of the support frame one 2 are symmetrically provided with draw-in grooves 16, and the two sides of the support frame two 3 are symmetrically provided with threaded holes, and the internal threads of the threaded holes are connected with threaded rods 17, One end of the threaded rod 17 is connected to a clamping block 18 , and the clamping block 18 is matched with the clamping slot 16 . As for the threaded rod 17 , an adjustment knob 19 is provided at the end of the threaded rod 17 away from the block 18 . For the adjustment seat 7 , a control switch 20 is installed on the surface of the adjustment seat 7 , and the control switch 20 is electrically connected with the motor 8 . For th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com