Geometry-Shaping Microwave Resonators

A resonator and microwave technology, used in resonators, waveguide-type devices, circuits, etc., can solve problems such as electromagnetic compatibility of external circuits, reduce the complexity of processing and assembly, expand the range of parasitic resonance frequencies, and improve processing. The effect of increased flexibility and process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

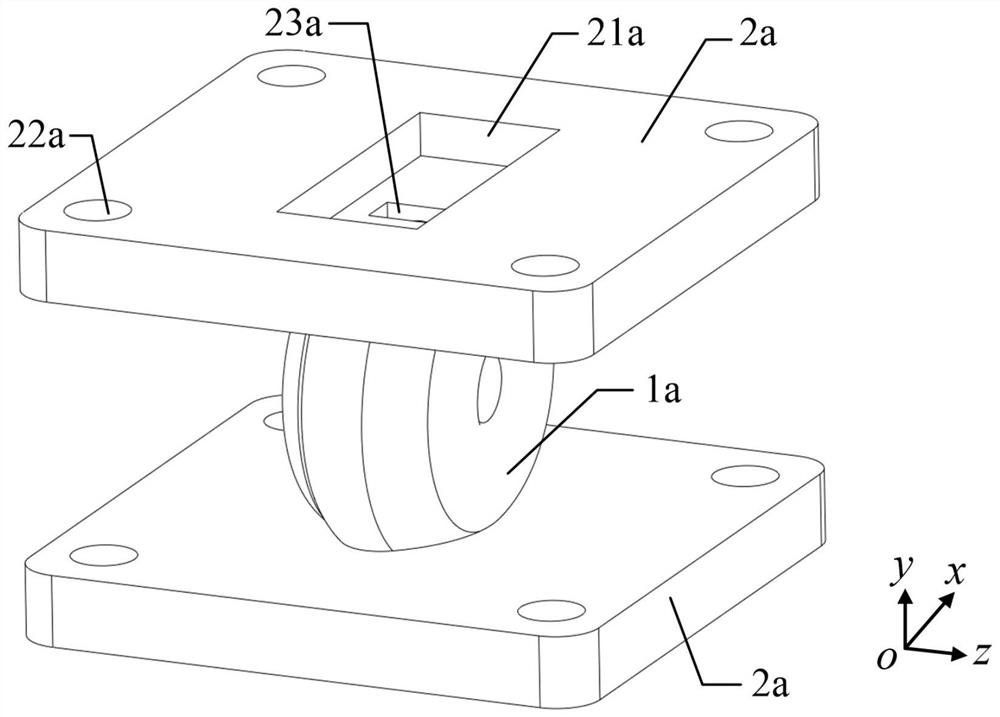

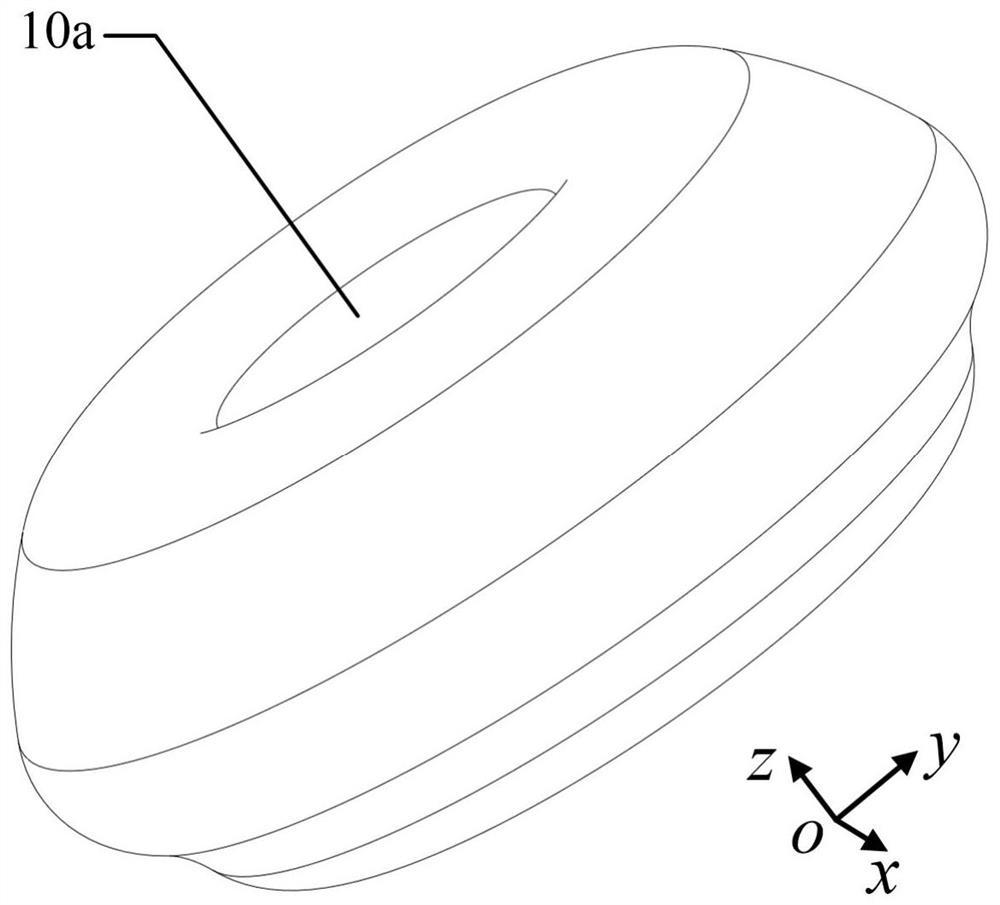

[0040] see figure 1 and figure 2 , figure 1 A three-dimensional structure diagram of a geometrically shaped microwave resonator provided in Embodiment 1 of the present invention. In Embodiment 1 of the present invention, the geometrically shaped microwave resonator includes a metal shell 1a and two waveguide flanges 2a, two coupling windows 23a are symmetrically opened on the metal shell 1a, and the two waveguide flanges 2a They are respectively arranged at two coupling windows 23a, and the waveguide flange 2a is provided with a feeding rectangular waveguide 21a communicating with the coupling window 23a. The setting of the two feeding rectangular waveguides 21a and the two coupling windows 23a can realize the The plastic resonant cavity 10a inside the body 1a performs two-port weak coupling feeding. Wherein, the plastic resonant cavity 10a is filled with air, and the metal shell 1a is made of metal, or is made of other insulating materials coated with a metal layer on the...

Embodiment 2

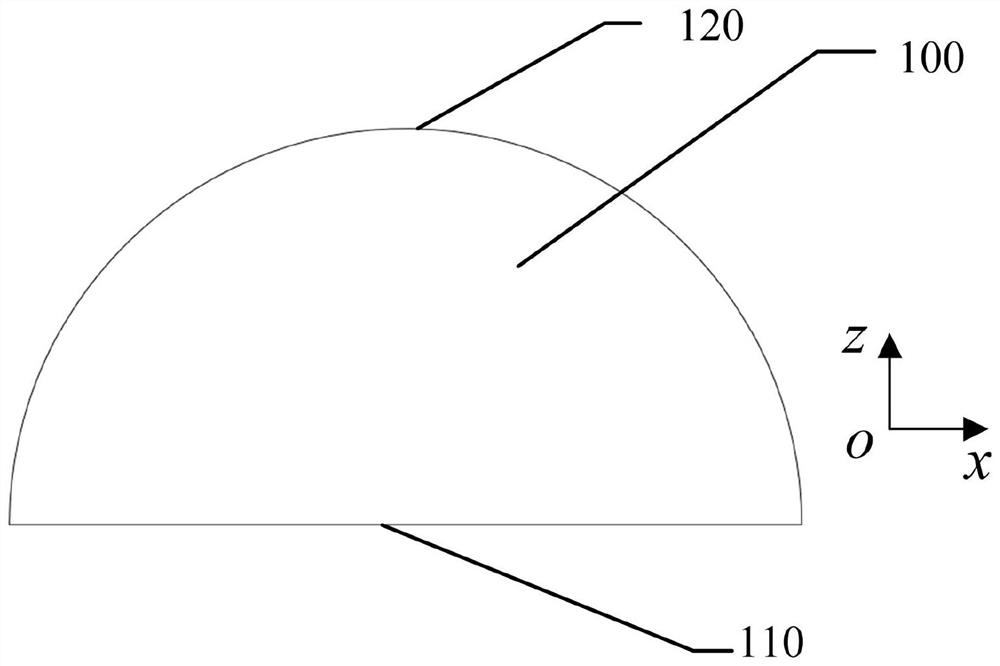

[0052] see Figure 6 and Figure 7 , Figure 6 A perspective view of a geometrically shaped microwave resonator provided in Embodiment 2 of the present invention, Figure 7 A cross-sectional view of the plastic resonant cavity 10b provided in Embodiment 2 of the present invention. The difference between the second embodiment and the first embodiment is that the size of the shaped resonant cavity 10b in the second embodiment is scaled down in the direction of the y axis, so that the cross section of the shaped resonant cavity 10a on the xoy plane is elliptical, namely The shaped resonant cavity 10b in the second embodiment can be equivalently considered to be shaped by an elliptical hemispherical cavity. The ratio of the short axis to the long axis of the elliptical hemispherical cavity is 0.5 to 1, and the shorter the short axis of the elliptical hemispherical cavity, the lower the unloaded Q value. In the direction of the ox axis, the dimensions of the irregular resonant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com