Printed matter defect detection method and device based on artifact elimination

A defect detection and printed matter technology, applied in measurement devices, optical testing of defects/defects, image enhancement, etc., can solve problems such as the effect of affecting printed matter detection, the time-consuming and laborious defect data pictures, and the algorithm not distinguishing between true and false defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further describe the technical solution of the present invention in detail, this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific steps.

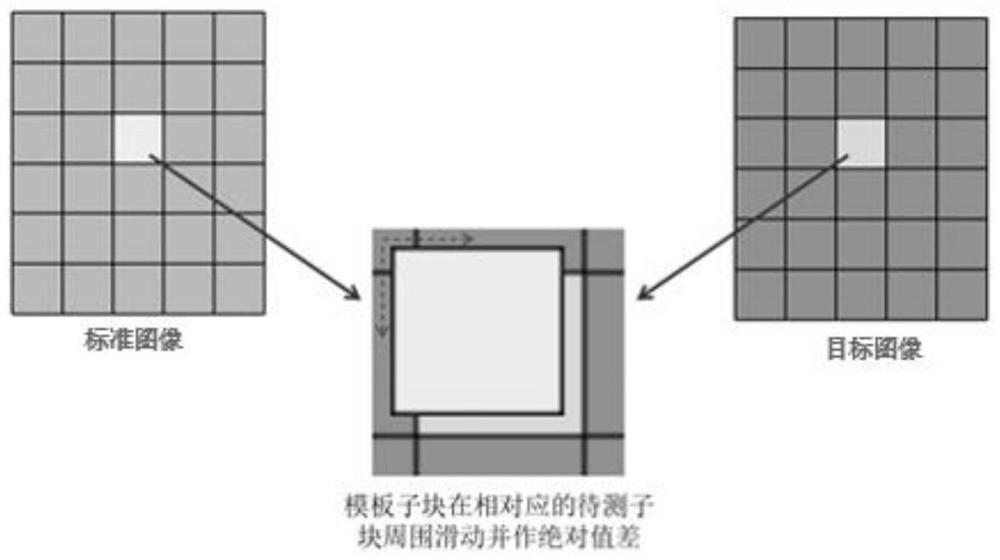

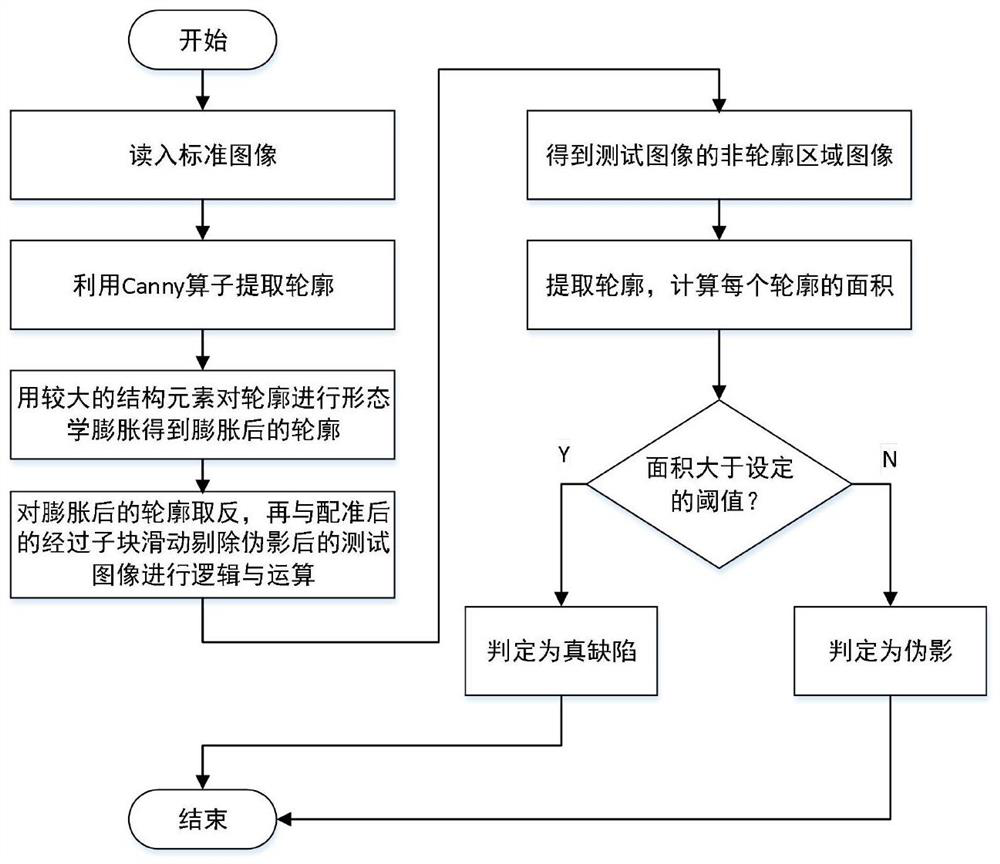

[0044] Such as figure 1 It is a schematic flow chart of an embodiment of the defect detection method of the present invention, and the specific implementation steps are as follows:

[0045] (1) Making a standard image: the embodiment first adopts a CMOS industrial camera with a resolution of 12 million to collect a template image on site, and set the template region ROI for the template image through the web interface template , search area ROI search and clipping region ROI crop , to extract template region ROI template Get the standard image G; set the number of template feature points (feature_num), template rotation angle step (angle_step), template rotation angle upper limit (angle_upper) and lower limit (angle_lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com