Metallographic corrosion method for simultaneously displaying austenitic stainless steel and aluminide coating organization structure on surface of austenitic stainless steel

A technology for simultaneously displaying austenitic stainless steel, applied in the direction of testing metal structures, preparation of test samples, and testing metals. The coating interface is distinct, the imaging effect is remarkable, and the outline is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

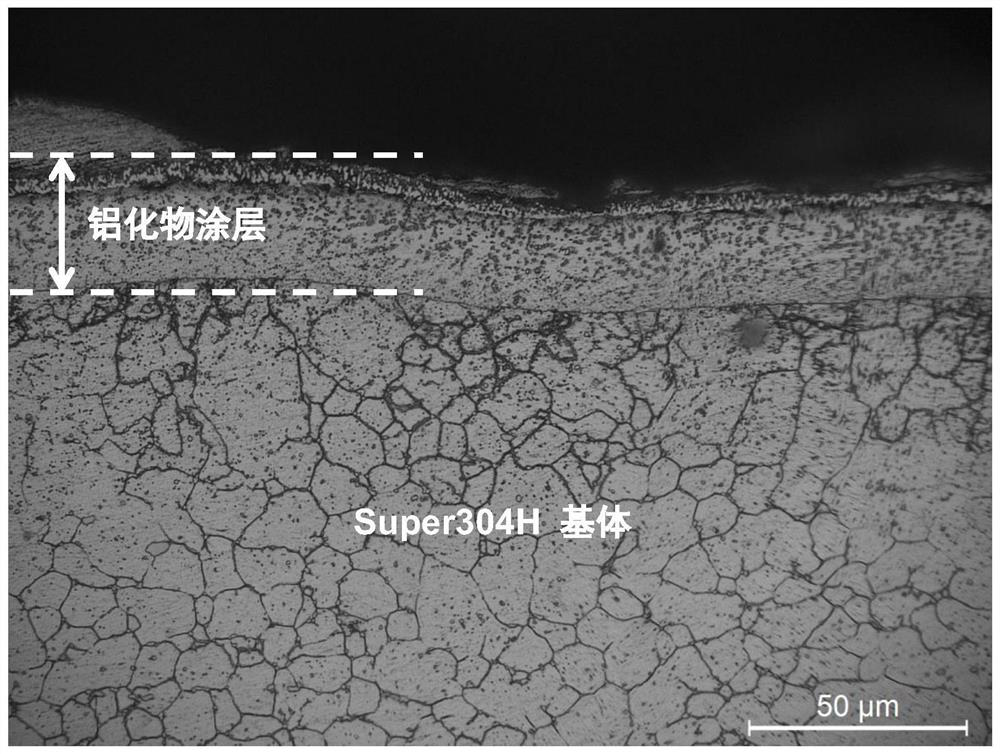

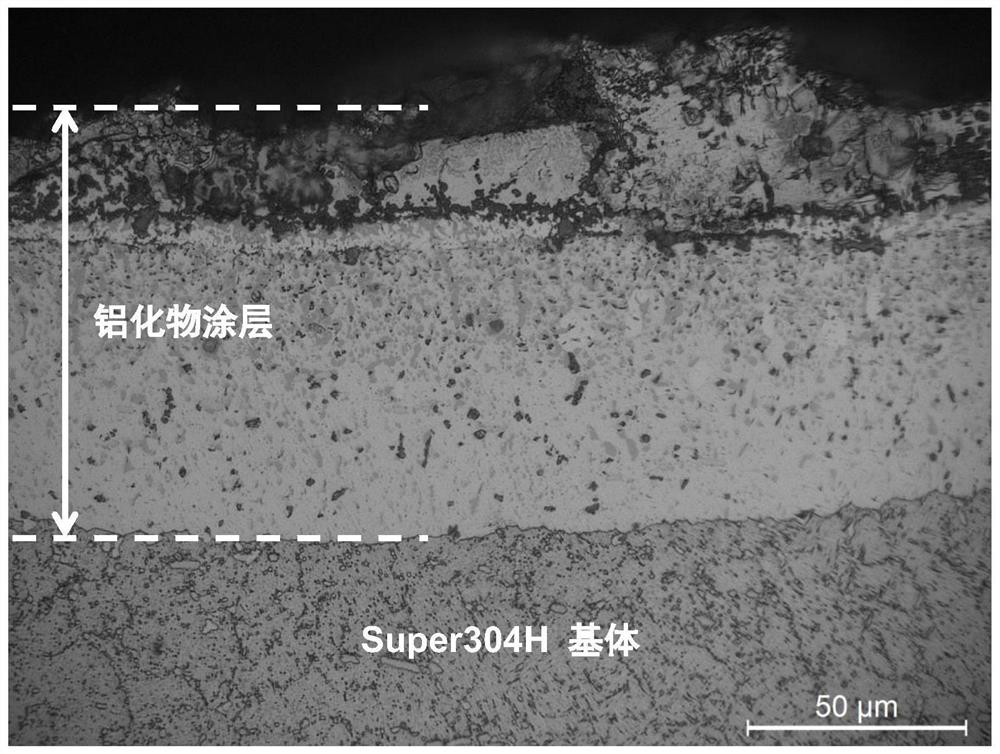

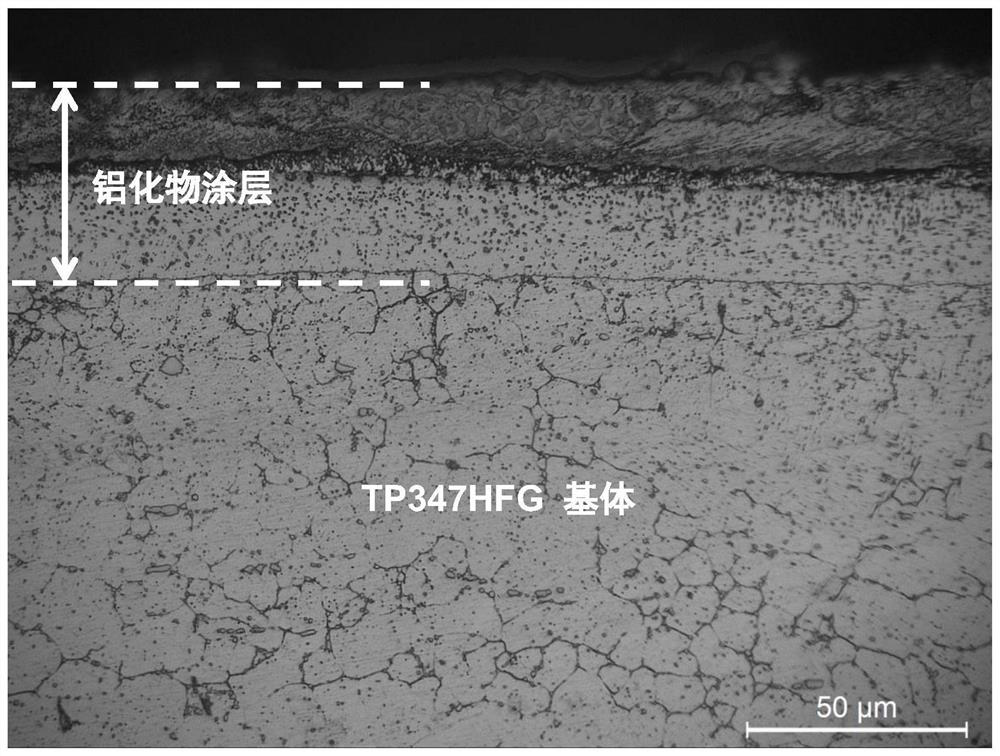

[0032] The present invention takes the aluminide coating samples on the surface of austenitic stainless steel Super304H and TP347HFG in the original state, service state and long-term service as examples to illustrate the embodiments of the present invention.

[0033] A metallographic corrosion method for simultaneously displaying the microstructure of austenitic stainless steel and its surface aluminide coating according to the present invention comprises the following steps:

[0034] Step 1: Preparation of metallographic etchant

[0035] Measure 40-55% hydrochloric acid (mass concentration is 38%), 37-48% ultrapure water and 8-12% glycerol respectively according to the volume percentage, and mix them to obtain the liquid phase. Add 7-16g of copper sulfate and 2-6g of ferric chloride to the phase, respectively weigh the corresponding proportions of copper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com