LED energy-saving lamp tube with external breakage-proof structure

A technology of LED energy-saving lamps and lamp tubes, which is applied to parts of lighting devices, damage prevention measures of lighting devices, semiconductor devices of light-emitting elements, etc., and can solve the problems of easily broken lamp tubes and poor heat dissipation effect of shatterproof lamp tubes , to achieve the effect of good anti-shattering effect, stable protection and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

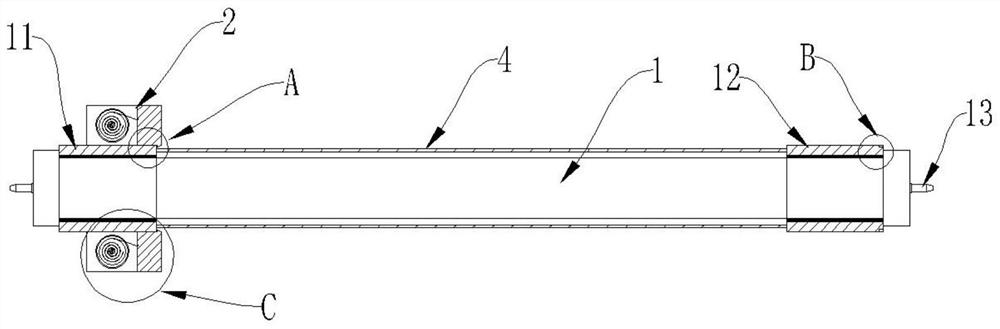

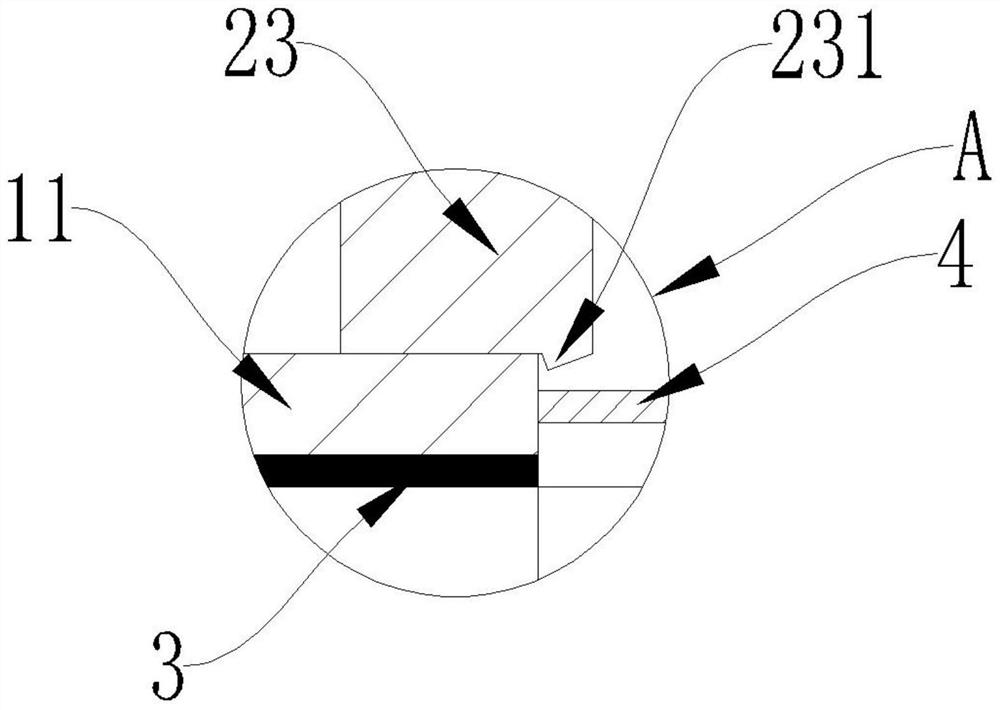

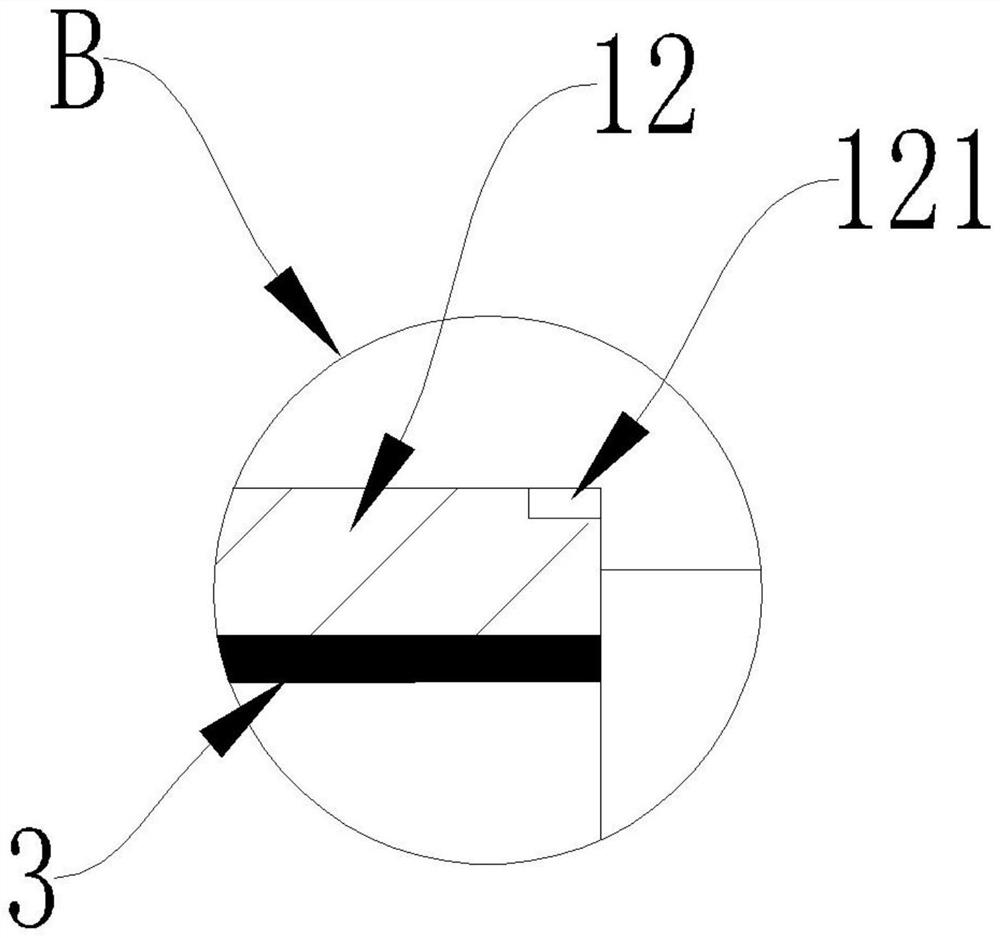

[0074] Further, as figure 1 with Figure 11 As shown, the diameter of the outer ring of the protection wire hiding part 22 is equal to the diameter of the outer ring of the protection wire tensioning part 23 .

[0075] In this embodiment, the outer diameters of the protection line hiding part 22 and the protection line stretching part 23 are the same, and the protection line hiding part 22 needs to accommodate the automatic winding structure 221 and the protection line 21 , so the thickness is greater than that of the protection line stretching part 23 . When the protection line 21 is crimped in the protection line hiding part 22 , the protection line stretching part 23 is in close contact with the protection line hiding part 22 . With such arrangement, it is convenient for the user to grasp the protective thread stretching member 23 when the protective thread 21 needs to be stretched and stretched.

Embodiment 2

[0077] Such as Figure 12 As shown, the protection line hiding part 22 is provided with an annular accommodation cavity 222 on the side close to the protection line stretching part 23. When the protection line 21 is crimped in the protection line hiding part 22, the protection line The wire stretching member 23 is clamped in the annular accommodating cavity 222 .

[0078] Compared with Embodiment 1, in this embodiment, an annular accommodation cavity 222 is provided on the side of the protection line hiding part 22 close to the protection line tensioning part 23, and the outer diameter of the protection line tensioning part 23 is smaller than or equal to the inner diameter of the annular accommodation cavity 222 ; When the protection line 21 is crimped in the protection line hiding part 22, the protection line stretching part 23 is located in the annular accommodation cavity 222. Such arrangement can make the structure of the protection assembly 2 more compact. In order to f...

Embodiment 3

[0080] Such as Figure 13 As shown, the protective wire 21 includes an inner protective wire 211 and an outer protective wire 212, and the automatic winding structure 221 includes a first automatic winding structure 223 and a second automatic winding structure 224;

[0081] Both ends of the inner protection line 211 are respectively connected to the first automatic winding structure 223 and the protection line stretcher 23;

[0082] The outer protection line 212 is respectively connected to the second automatic winding structure 224 and the protection line tension member 23;

[0083] The second automatic thread winding structure 224 is located on the side of the first automatic thread winding structure 223 away from the center of the protection thread hiding part 22 .

[0084] Equivalently, there are two layers of protection lines 21 (inner protection line 211 and outer protection line 212) in a protection component 2, wherein the inner protection line 211 is close to the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com